Ammonia-spraying mixing system utilizing external filtration type dust remover air purifying chamber structure

A hybrid system and clean gas chamber technology, applied in the field of flue gas purification, can solve problems such as short mixing length, increased system operating resistance, and low flue gas flow rate, so as to reduce system operating energy consumption, avoid system resistance increase, and system The effect of a small increase in resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

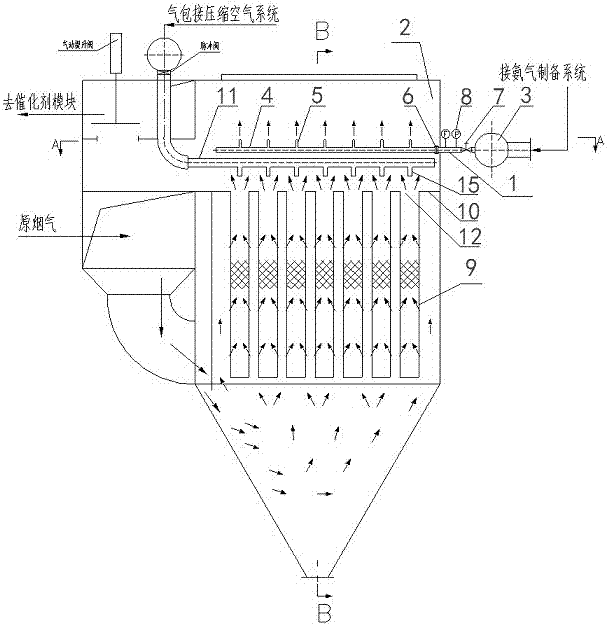

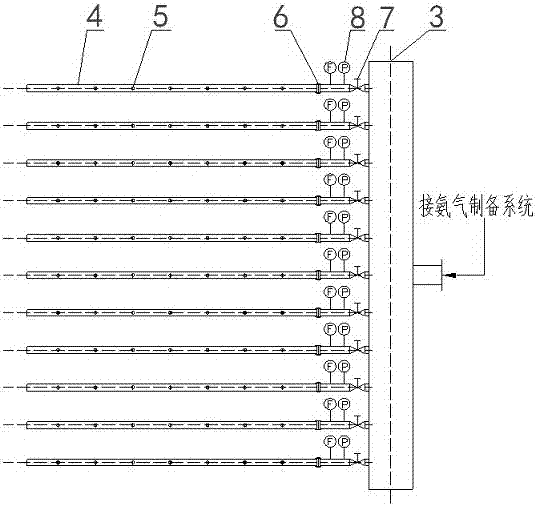

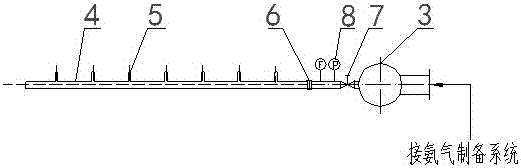

[0064] Such as image 3 , Figure 4 and Figure 5 As shown, a plurality of ammonia gas branch pipes 4 share one ammonia gas main pipe assembly 3, and the ammonia gas main pipe assembly 3 is externally connected to the ammonia gas preparation system; the ammonia gas branch pipe 4 installed in the clean gas chamber 2 is connected to the ammonia gas main pipe assembly by a flange 6 3. Each ammonia branch pipe 4 is correspondingly equipped with a flow regulating valve 7 and a detection instrument group 8 to control the flow of ammonia gas in each branch pipe; in the clean air chamber 2, a plurality of filter elements 9 share a dust-cleaning compressed air injection pipe 11. Each blowing pipe 11 is equipped with a plurality of compressed air nozzles 15; on the back of each blowing pipe 11, an ammonia gas branch pipe 4 is installed correspondingly, and each ammonia gas branch pipe 4 is equipped with a plurality of ammonia gas nozzles 5; Each ammonia gas nozzle 5 corresponds to one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com