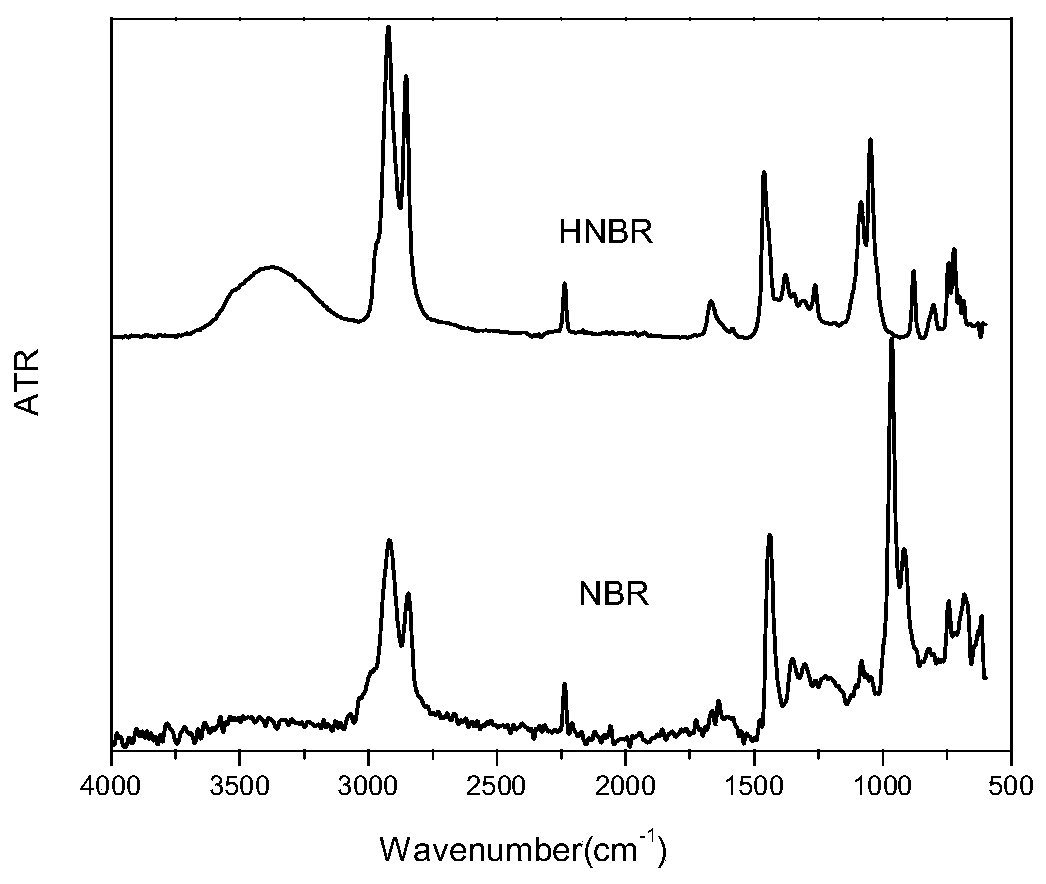

Preparation of a magnetic carbon nanotube-supported rhodium catalyst and its application in selective hydrogenation of nitrile rubber

A magnetic carbon nanotube, catalyst catalyzed nitrile technology, applied in physical/chemical process catalysts, chemical/physical processes, chemical instruments and methods, etc., can solve the problem of HNBR production cost increase, hydrogenation selectivity is not as good as rhodium, HNBR performance Reduce and other problems, to achieve the effect of good recovery and recycling performance, good selectivity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of magnetic carbon nanotube supported rhodium catalyst in the present embodiment is as follows:

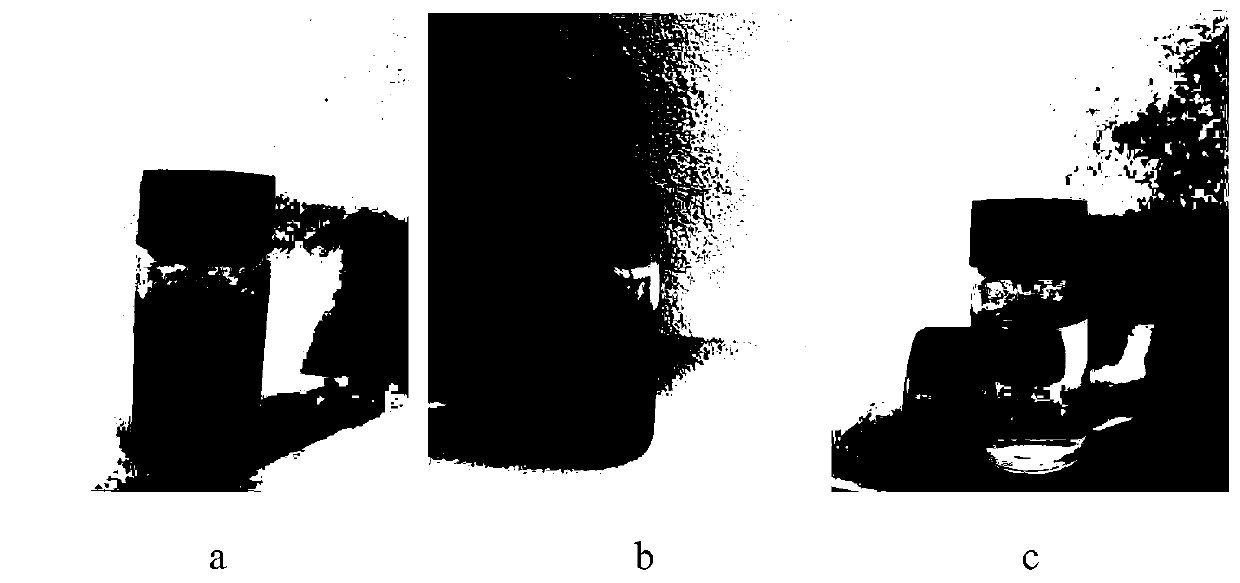

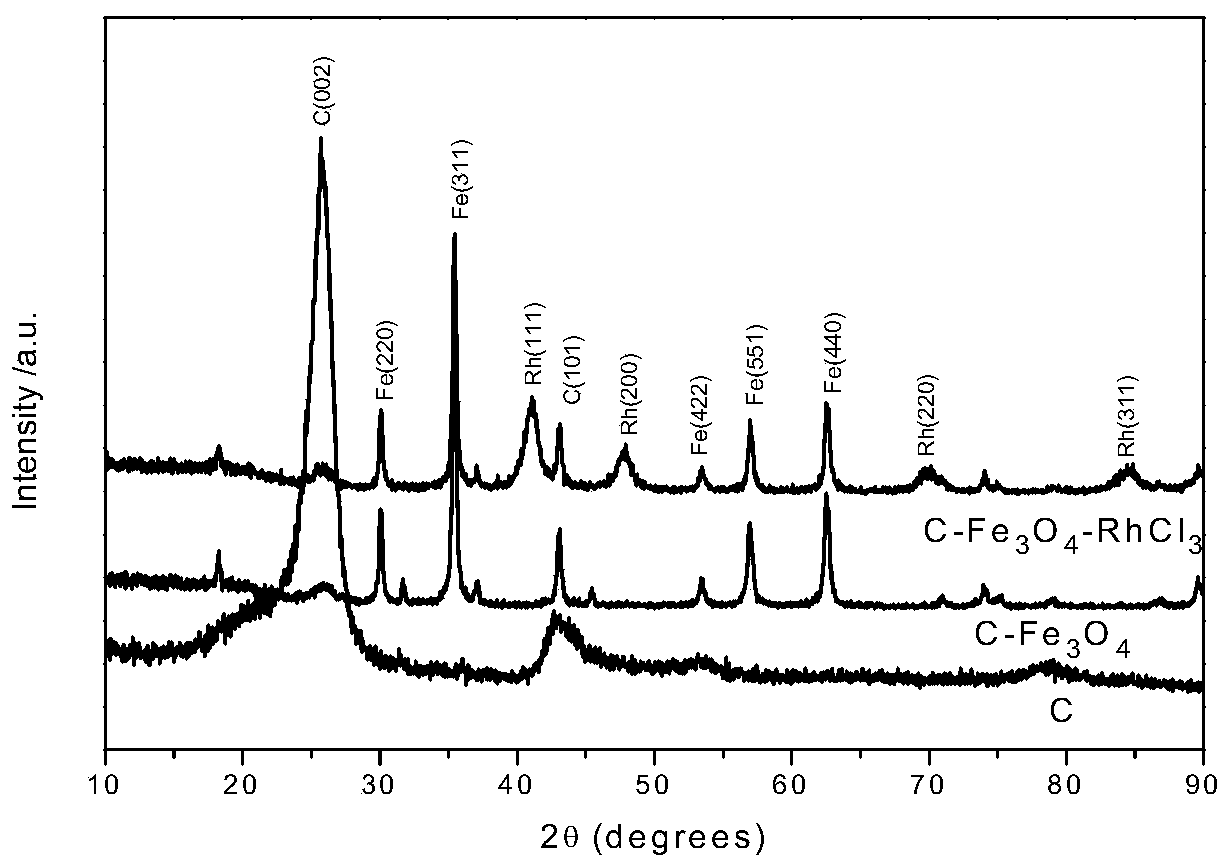

[0028] Step 1: Preparation of magnetic carbon nanotubes

[0029] Take 0.3g of carbon nanotubes in 75ml of ethylene glycol and sonicate for 5 hours, then add 2.0g of ferric chloride and 4.2g of sodium acetate to the above solution, stir magnetically for 2 hours, homogenize, place in a hydrothermal reaction kettle, and put in water at 200°C After thermal reaction for 8 hours, after the completion of the reaction, magnetic separation removes unmagnetized carbon nanotubes to obtain magnetic carbon nanotubes (C-Fe 3 o 4 ).

[0030] Step 2: Preparation of magnetic carbon nanotube-supported rhodium catalyst

[0031] Take 0.4g of C-Fe prepared in step 1 3 o 4 Ultrasonic disperse in ethanol solvent for 3 hours, then add 100mg rhodium trichloride, react at 120°C for 30 minutes, cool to room temperature after the reaction, and magnetically separate to obtai...

Embodiment 2

[0035] The reaction time of hydrogenating NBR was set to 2h, 4h, 6h, 8h, 10h, 12h respectively, and other preparation parameters remained unchanged, in order to study the influence of different catalytic hydrogenation time on the hydrogenation degree of NBR. The experimental results are shown in Table 1.

[0036] Table 1 Effect of different catalytic hydrogenation time on NBR hydrogenation degree

[0037] Time(h) 2 4 6 8 10 12 HD(%) 69.32 80.63 94.26 98.17 98.25 98.54

[0038] It can be seen from Table 1 that with the increase of time, the hydrogenation degree of NBR is constantly increasing, but a good effect has been achieved at about 8h.

Embodiment 3

[0040] The reaction pressure of hydrogenated NBR in Example 1 was changed to 1MPa, 2MPa, 3MPa, 4MPa, 5MPa, and other preparation parameters were kept unchanged to study the influence of different reaction pressures on the hydrogenation degree of NBR. The experimental results are shown in Table 2.

[0041] Table 2 The influence of different reaction pressures on the hydrogenation degree of NBR

[0042] Pressure (MPa) 1 2 3 4 5 HD(%) 68.85 83.38 87.56 98.17 98.25

[0043] It can be seen from Table 2 that with the increase of hydrogenation pressure, the hydrogenation degree of NBR is constantly increasing, but it has achieved good results at around 4MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com