Preparation technology of ceramic dielectric resonator for TM communication

A technology of ceramic dielectric and preparation process, which is applied to waveguide-type devices, electrical components, circuits, etc., can solve the problems of high manufacturing cost, high energy consumption and high temperature, and achieve low cost of raw materials, fine and uniform grains, and improved performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Describe the present invention in detail with specific embodiment below in conjunction with accompanying drawing:

[0027] Environmentally friendly microwave dielectric ceramics for the L-band, the manufacturing raw materials contain ingredients: barium oxide (BaO) titanium dioxide (TiO 2 ), zinc oxide (ZnO) and niobium pentoxide (Nb 2 o 5 ) and trace doping additive components; it is characterized in that: the trace additive also contains the proportioning and manufacturing method of manganese oxide (MnO), copper oxide (CuO) trace additive, and table 1 provides each embodiment The data, table 2 provides the performance of each embodiment.

[0028] Table 1:

[0029]

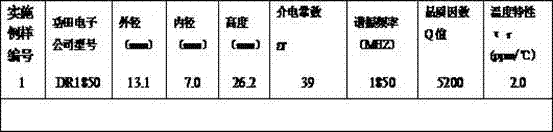

[0030] Table 2: Main performance of resonators of various specifications in TM mode

[0031]

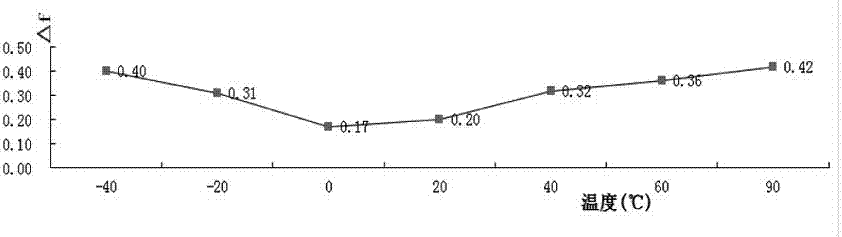

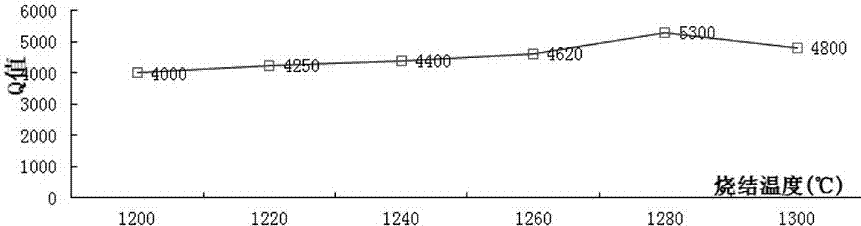

[0032] Figure 1~2 By summarizing the changing trend of formula and properties, it is convenient to adjust the formula and obtain microwave dielectric ceramics with required properties.

[0033] figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| q value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com