Master batch for degradable mulching films and preparation method of master batch

A technology for degrading mulch and masterbatch, which is applied in the field of color masterbatch, can solve the problems of different requirements for mulch, restrictions on popularization and application, and difficulty in degradation, etc., and achieve good mechanical properties and water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

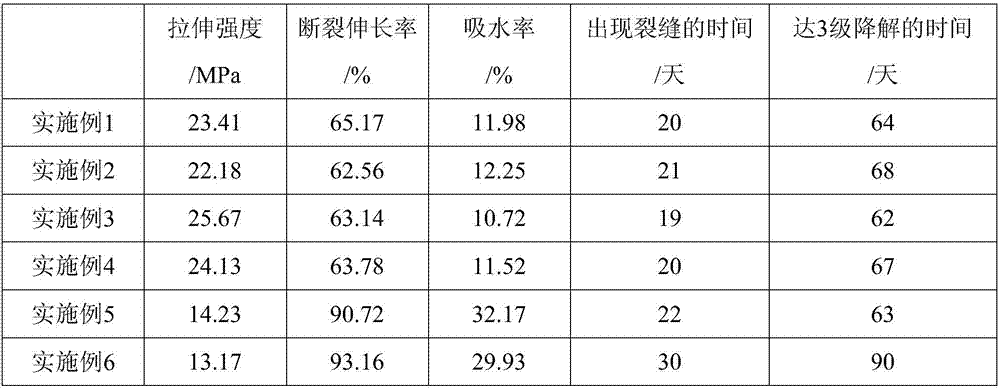

Examples

Embodiment 1

[0020] A kind of color masterbatch for degradable mulching film, the raw material includes by weight: 40 parts of ethylene-vinyl acetate copolymer, 8 parts of polycarbonate, 4 parts of polyvinyl alcohol, 2 parts of polylactic acid, 0.8 part of sodium alginate, large 0.5 parts of soybean oil, 3 parts of cellulose, 2 parts of vegetable starch, 1 part of titanium dioxide, 3 parts of dispersant, 2 parts of compatibilizer, 1 part of plasticizer, and 2 parts of pigment.

[0021] The content of vinyl acetate in the ethylene-vinyl acetate copolymer is 15%.

[0022] The vegetable starch is corn starch.

[0023] The cellulose is hydroxypropylmethylcellulose.

[0024] The polycarbonate is aromatic polycarbonate.

[0025] The plasticizer is ethylene glycol.

[0026] The dispersant is stearic acid.

[0027] The preparation method of the above-mentioned degradable mulch masterbatch comprises the following steps:

[0028] Step 1, mix ethylene-vinyl acetate copolymer, polycarbonate, poly...

Embodiment 2

[0031] A kind of color masterbatch for degradable mulching film, the raw material includes by weight: 43 parts of ethylene-vinyl acetate copolymer, 11 parts of polycarbonate, 6 parts of polyvinyl alcohol, 3 parts of polylactic acid, 1.4 parts of sodium alginate, large 0.8 parts of soybean oil, 5 parts of cellulose, 4 parts of vegetable starch, 2 parts of titanium dioxide, 6 parts of dispersant, 3 parts of compatibilizer, 2 parts of plasticizer, and 4 parts of pigment.

[0032] The content of vinyl acetate in the ethylene-vinyl acetate copolymer is 12%.

[0033] The vegetable starch is a mixture of wheat starch and sweet potato starch, and the weight ratio of wheat starch and sweet potato starch is 1:1.

[0034] The cellulose is hydroxyethyl cellulose.

[0035] The polycarbonate is aromatic polycarbonate.

[0036] The plasticizer is ethylene glycol.

[0037] The dispersant is magnesium stearate.

[0038] The preparation method of the above-mentioned degradable mulch masterb...

Embodiment 3

[0042] A kind of color masterbatch for degradable mulching film, the raw material includes by weight: 48 parts of ethylene-vinyl acetate copolymer, 16 parts of polycarbonate, 7 parts of polyvinyl alcohol, 5 parts of polylactic acid, 1.7 parts of sodium alginate, large 0.9 parts of soybean oil, 7 parts of cellulose, 5 parts of vegetable starch, 4 parts of titanium dioxide, 7 parts of dispersant, 5 parts of compatibilizer, 3 parts of plasticizer, and 8 parts of pigment.

[0043] The content of vinyl acetate in the ethylene-vinyl acetate copolymer is 14%.

[0044] The vegetable starch is rice starch.

[0045] The cellulose is hydroxypropylmethylcellulose.

[0046] The polycarbonate is aromatic polycarbonate.

[0047] The plasticizer is a mixture of sorbitol and glycerin, and the weight ratio of sorbitol and glycerin is 1:2.

[0048] The dispersant is stearic acid.

[0049] The preparation method of the above-mentioned degradable mulch masterbatch comprises the following steps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com