Biodegradable plastic and preparation method thereof

A biodegradable plastic and biodegradable resin technology, applied in the field of plastic products, can solve the problems of limited compatibility and insufficient mechanical properties, and achieve the effects of increased compatibility, good mechanical properties and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

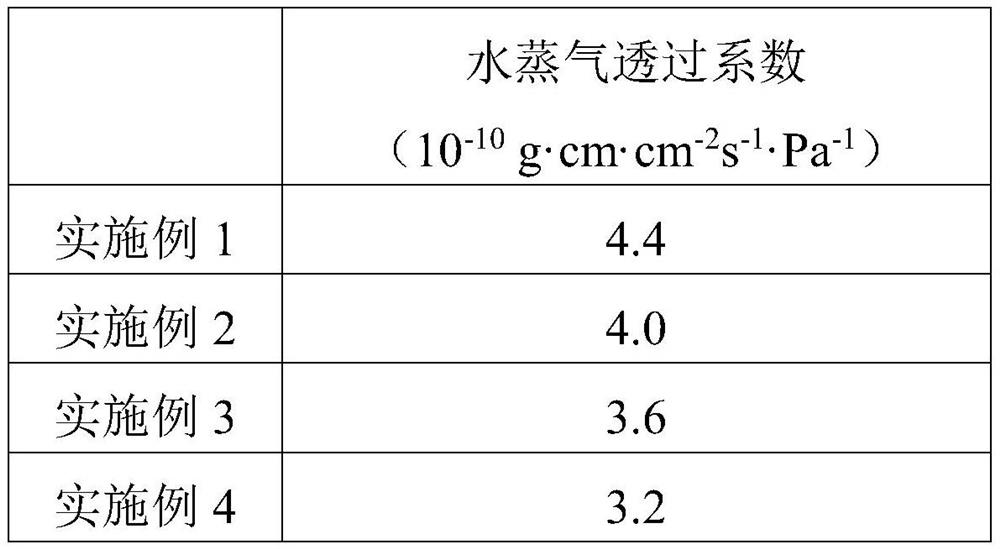

Examples

Embodiment 1

[0040] A method for producing a biodegradable plastic is: weighing 40 g of a biodegradable resin in a 70 ° C drying tank and drying 24h and 20 g of potato starch, 1 g diphenylmethane-4,4'-diisocyanate, 1 g butyl Hydroxy anise ether, 1 g of calcium stearate, 3G PEG600, plasticized granulation in three screw extruders, resulting in biodegradable plastic; extrusion temperature is 160 ° C.

[0041] The biodegradable resin is a mass ratio of 2: 1 (adipate-co-benzothylene terephthalate) and a mixture of polylactic acid.

Embodiment 2

[0043] A method of preparing a biodegradable plastic is: weighing 40 g of biodegradable resin in a 70 ° C drying tank for 24 h and 20g modified potato starch, 1 g diphenylmethane-4,4'-diisocyanate, 1g Butylhydroxynediocene ether, 1 g of calcium stearate, 3G PEG600 is plasticized and granulated in three screw extruders to obtain biodegradable plastic; the extrusion temperature is 160 ° C.

[0044] The biodegradable resin is a mass ratio of 2: 1 (adipate-co-benzothylene terephthalate) and a mixture of polylactic acid.

[0045] The preparation method of modified potato starch includes the steps of:

[0046] (1) 20mL 90 wt% ethanol, 30 ml of water, 15 ml ammonia water in 30 ° C to obtain a solution L 1 ; 50 ml of 90 wt% ethanol solution, 1.0 ml of tetraethyl ester at 30 ° C to give a solution L 2 Reduce solution 2 Add to solution L 1 In 30 ° C, the reaction was stirred at 30 ° C for 2 h, 6 ml of tetraeth ester was added, and then the resulting solid was placed at 60 ° C drying tank af...

Embodiment 3

[0050] The preparation method of biodegradable plastic is: 120 g of a biodegradable resin is placed in a 70 ° C drying tank for 24 h and 20g modified potato starch, 5 g of coconut shell fibers, 1 g diphenylmethane-4, 4 ' - Diisocyanate, 1 g butyl hydroxylholder ether, 1 g of calcium stearate, 3G PEG600 is plasticized and granulated in three screw extruders, resulting in biodegradable plastic; extrusion temperature is 160 ° C.

[0051] The biodegradable resin is a mass ratio of 2: 1 (adipate-co-benzothylene terephthalate) and a mixture of polylactic acid.

[0052] The preparation method of modified potato starch includes the steps of:

[0053] (1) 20mL 90 wt% ethanol, 30 ml of water, 15 ml ammonia water in 30 ° C to obtain a solution L 1 ; 50 ml of 90 wt% ethanol solution, 1.0 ml of tetraethyl ester at 30 ° C to give a solution L 2 Reduce solution 2 Add to solution L 1 In 30 ° C, the reaction was stirred at 30 ° C for 2 h, 6 ml of tetraeth ester was added, and then the resulting so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com