Preparation method of amido functionalized gamma-aluminum oxide thin film

A technology of aluminum oxide and amine-based functions, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of good adsorption performance, achieve high removal rate, efficient method, Good water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Take 5.67g of aluminum isopropoxide and add it to 50ml of deionized water at 70°C under strong stirring, add 0.2ml of glacial acetic acid dropwise, stir for 1 hour, add 0.3g of PVA solution that has been dissolved in 90°C and 10ml of deionized water, and mix. Then continue to stir at room temperature for a period of time to obtain a sol, transfer the sol to a hydrothermal kettle for 6 hours at 150°C, cool to room temperature, and tape-cast the obtained aluminum sol on a polytetrafluoroethylene sheet. After natural drying for 48 hours, it was peeled off, and the obtained sample was heated in a microwave muffle furnace at 1.5°C / min, and calcined at 600°C for 1 hour to obtain γ-Al 2 o 3 film.

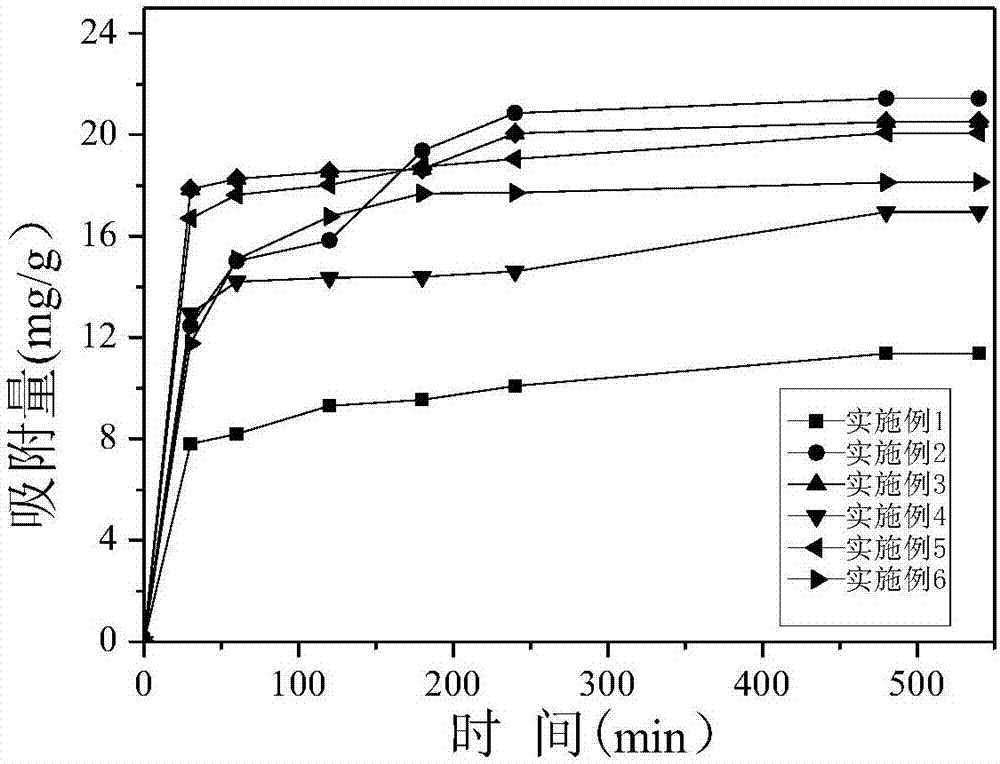

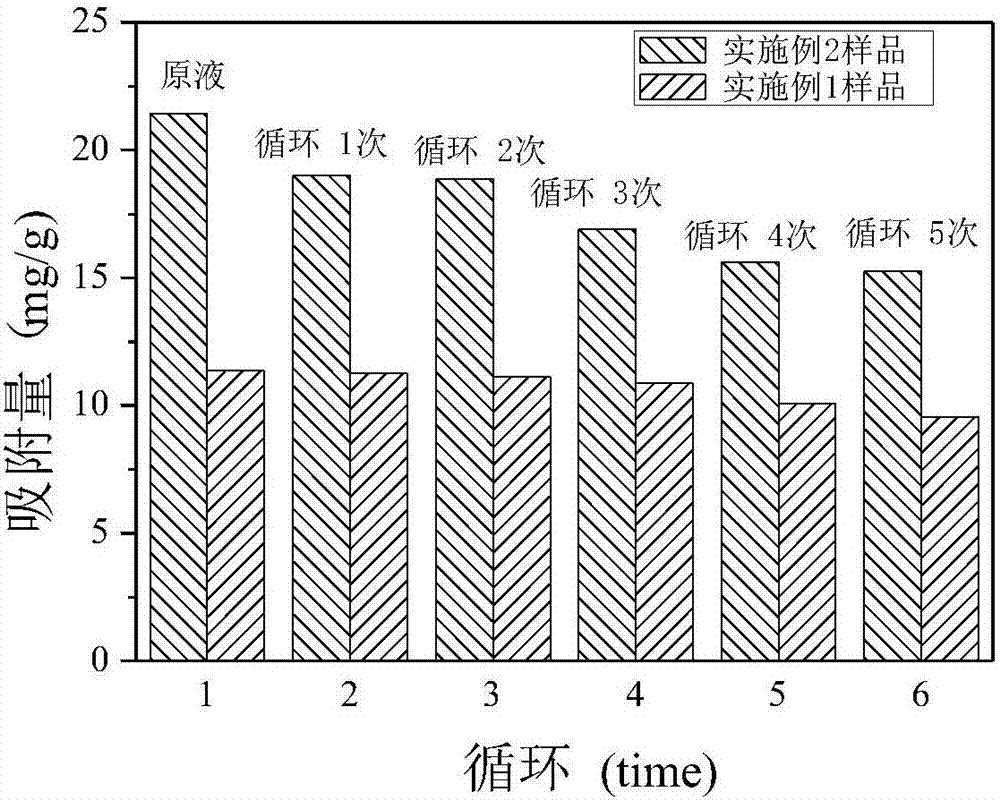

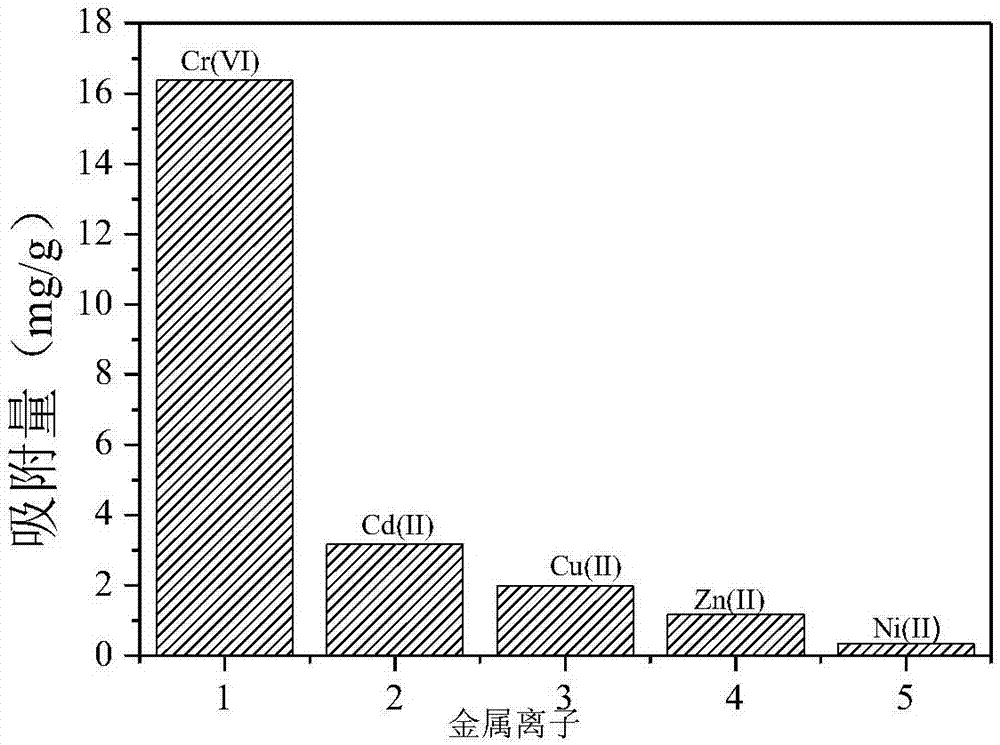

[0033] When absorbing 100ml, 50mg / L Cr(VI) solution, adjust the pH=3 with a hydrochloric acid solution with a concentration of 1mol / L, then add 0.2g of unmodified aluminum oxide film sample, and set the parameters of the constant temperature oscillation box to 25°C, 150r / min. Unm...

Embodiment 2

[0035] Take 5.67g of aluminum isopropoxide and add it to 50ml of deionized water at 70°C under strong stirring, add 0.2ml of glacial acetic acid dropwise, stir for 1 hour, add 0.3g of PVA solution that has been dissolved in 90°C and 10ml of deionized water, and mix. Then continue to stir at room temperature for a period of time to obtain a sol, transfer the sol to a hydrothermal kettle for 6 hours at 150°C, cool to room temperature, and tape-cast the obtained aluminum sol on a polytetrafluoroethylene sheet. After natural drying for 48 hours, it was peeled off, and the obtained sample was heated in a microwave muffle furnace at 1.5°C / min, and calcined at 500°C for 3 hours to obtain γ-Al 2 o 3 film. Take 2g of the film and add it into 100ml of absolute ethanol dissolved in 3ml of 3-aminopropyl-triethoxysilane, shake and dip for 24 hours, wash with 20ml of absolute ethanol three times and dry to obtain the amino-functionalized γ-Al 2 o 3 Film samples.

[0036] When absorbing...

Embodiment 3

[0039] Take 5.67g of aluminum isopropoxide and add it to 50ml of deionized water at 70°C under strong stirring, add 0.2ml of glacial acetic acid dropwise, stir for 1 hour, add 0.3g of PVA solution that has been dissolved in 90°C and 10ml of deionized water, and mix. Then continue to stir at room temperature for a period of time to obtain a sol, transfer the sol to a hydrothermal kettle for 6 hours at 150°C, cool to room temperature, and tape-cast the obtained aluminum sol on a polytetrafluoroethylene sheet. After 48 hours of natural drying, the obtained sample was heated in a microwave muffle furnace at 1.5°C / min, and then calcined at 525°C for 2.5 hours to obtain γ-Al 2 o 3 film. Take 2g of the film and add it to 100ml of absolute ethanol dissolved in 0.5ml of PEI. After immersion for 24h, it is washed with 20ml of absolute ethanol for 3 times and dried to obtain amine-functionalized γ-Al 2 o 3 film.

[0040] When absorbing 100ml, 50mg / L Cr(VI) solution, adjust pH=3 with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com