Preparation method of conductive adhesive and conductive adhesive

A technology of conductive glue and conductive balls, applied in the direction of conductive adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of conductive adhesive conduction, cyanide gold plating toxicity, complex process, etc., to achieve Enhanced electrical conductivity, reduced cost, and ease of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to further explain the technical means adopted by the present invention and its effects, the following describes in detail the preferred embodiments of the present invention and the accompanying drawings.

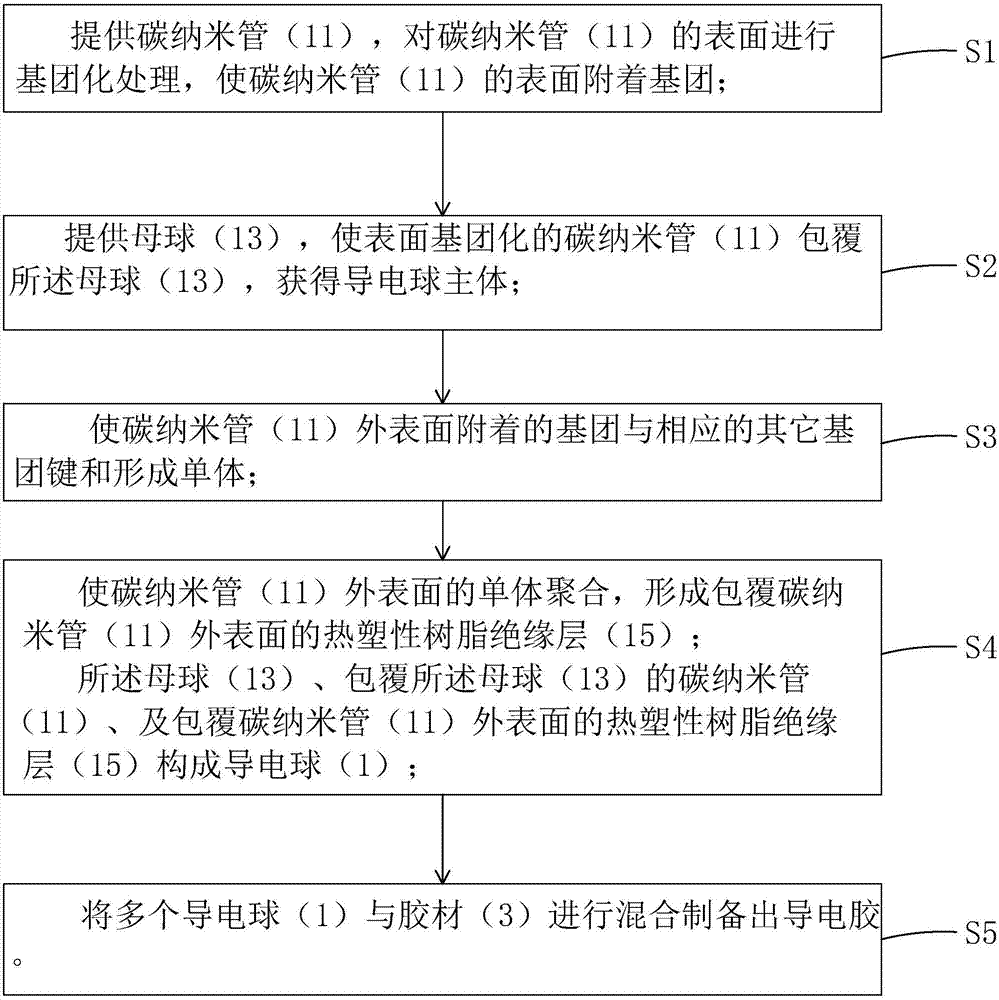

[0044] See figure 1 , The present invention first provides a method for preparing conductive adhesive, including the following steps:

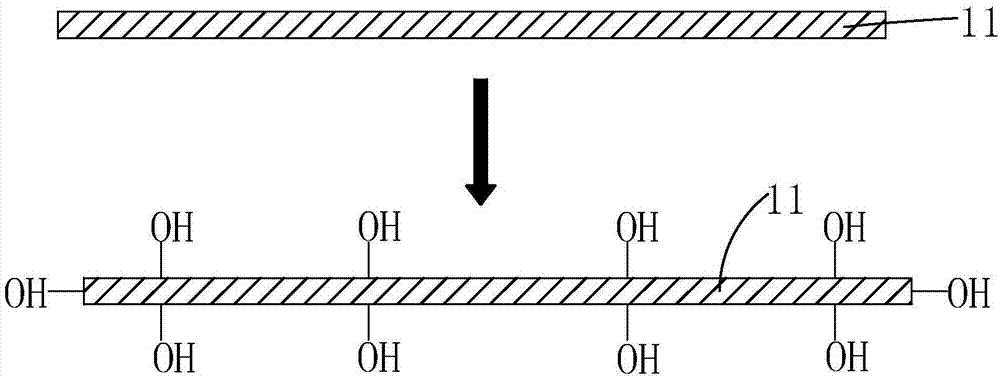

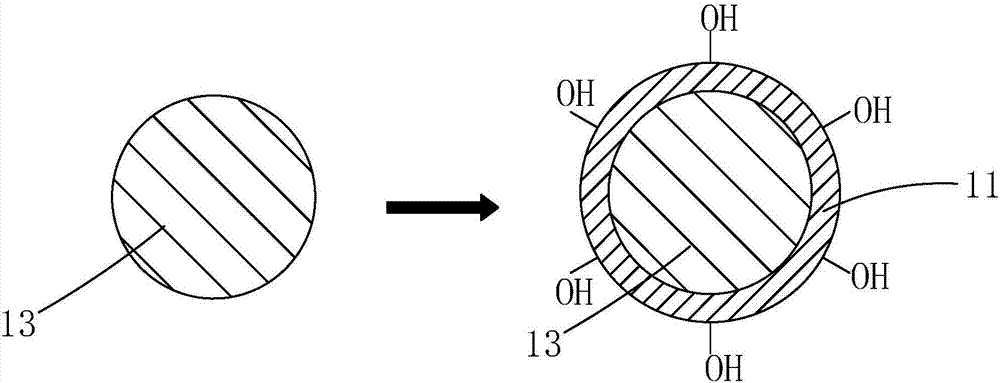

[0045] Step S1, such as figure 2 As shown, carbon nanotubes 11 are provided, and the surface of the carbon nanotubes 11 is grouped to attach groups to the surface of the carbon nanotubes 11.

[0046] Specifically, in the step S1, the surface of the carbon nanotube 11 is hydroxylated, carboxylated, aminated, or acylated, so that the surface of the carbon nanotube 11 is attached with a hydroxyl group (-OH) and a carboxyl group (-COOH). , Amino (-NH2), or acyl (RM(O)-, where M is carbon (C)), etc.

[0047] Taking the step S1 to perform hydroxylation treatment on the surface of the carbon nanotube 11 to make the surface of the carbon n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com