A kind of silver composite iron oxide fiber and its preparation method and application

A composite iron oxide and fiber technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve the problem of reduced catalytic activity and the inability of simulated enzymes to have both high activity and High stability, high production cost and other problems, to overcome the effects of easy reunion, unfavorable recycling and reuse, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

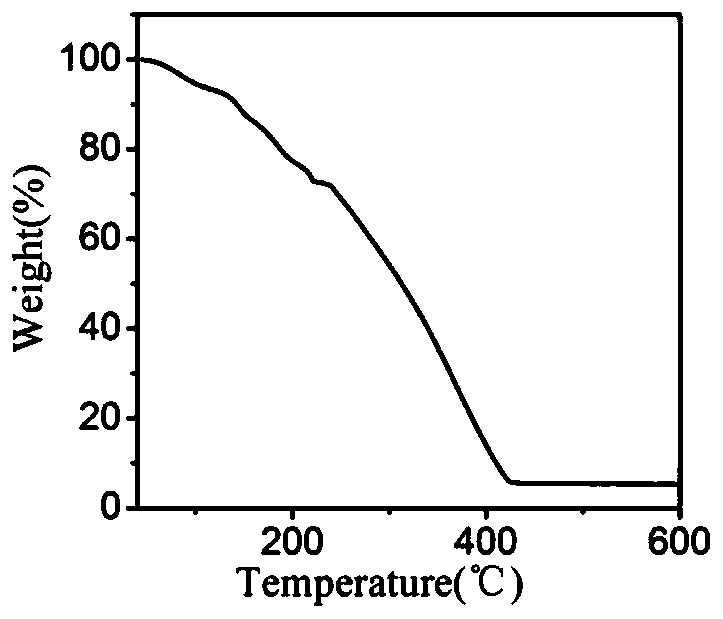

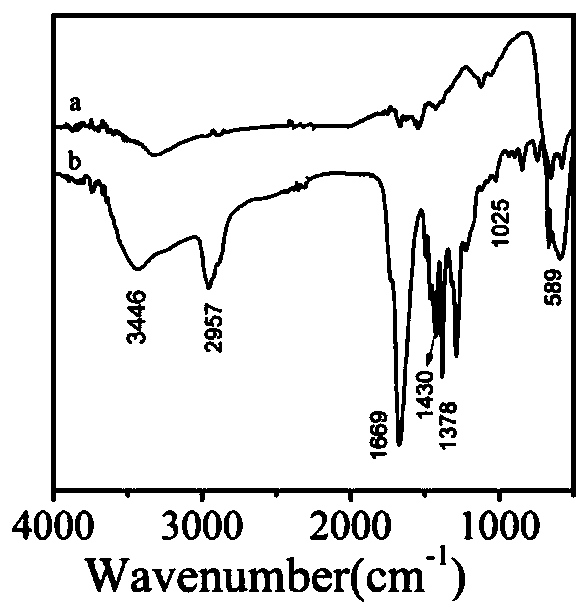

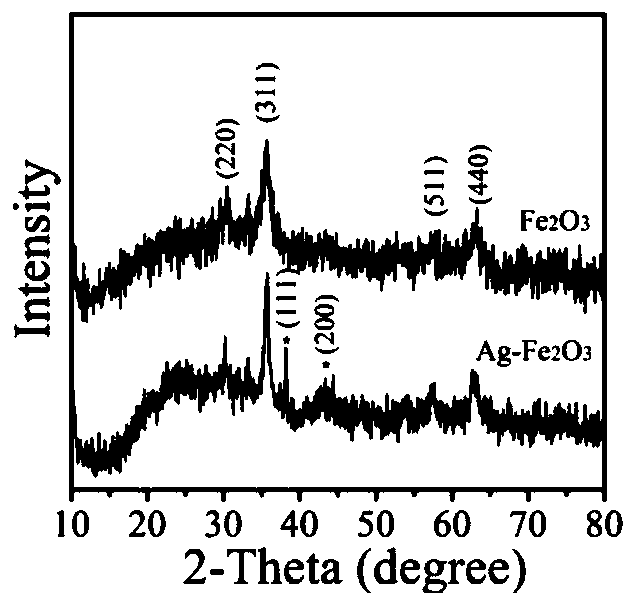

[0051] 1.5g polyvinylpyrrolidone (PVP) was dissolved in 15mL ethanol under magnetic stirring, and after the PVP was completely dissolved, a polymer solution was obtained, and 0.45g Fe(NO 3 ) 3 9H 2 O, 0.015g AgNO 3 , 0.46g citric acid was placed in water to prepare 4.5mL salt solution, the salt solution was added to the polymer solution, and stirred on a constant temperature magnetic stirrer until there were no small bubbles in the solution, and a uniform, yellow-brown solution with a viscosity of 30Pa was obtained. · s precursor sol solution. Inject the precursor sol solution into the needle tube, set the voltage of the electrospinning machine to 20KV, the receiving distance to 20cm, and the advancing speed to 0.002mm / s; collect the prepared gel fiber after spinning and place it at 80°C Dry in the oven for at least 12 hours. The fiber is calcined to remove impurities and organic matter, and the final product obtained is Ag-Fe 2 o 3 The composite fiber, wherein the calci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com