Determination method for lead content in polydimethylsiloxane and emulsion thereof

A technology of polydimethylsiloxane and determination method, which is applied in the field of physical and chemical testing, can solve problems such as cumbersome operation procedures, incomplete digestion, and long reaction time, and achieve the effects of accurate detection results, thorough digestion, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

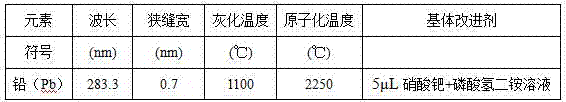

Examples

Embodiment 1

[0027] A method for assaying lead content in polydimethylsiloxane, the steps comprising:

[0028] (1) Sample processing:

[0029] Accurately weigh 0.5g of the polydimethylsiloxane sample to be tested into a polytetrafluoroethylene digestion tank, add 4mL of nitric acid and 4mL of hydrofluoric acid respectively, after microwave digestion (see Table 1 for the digestion conditions), put the acid on the electric heating plate 140 ℃ to 1~2mL of the remaining liquid, transferred to a 25mL plastic volumetric flask, shaken to volume with ultrapure water and ready to be tested.

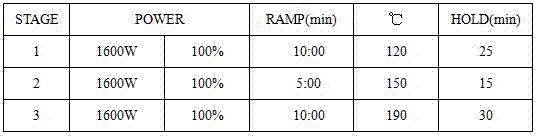

[0030] Table 1 Determination conditions of microwave digestion apparatus

[0031]

[0032] (2) Solution preparation:

[0033] Standard blank solution: prepare 1wt% nitric acid deionized aqueous solution as the standard blank solution;

[0034] Get the lead standard solution in a volumetric flask, make it to volume with a standard blank solution, and prepare a lead standard stock solution of 100mg / L, then...

Embodiment 2

[0056] The assay method of lead content in polydimethylsiloxane emulsion, the step comprises:

[0057] (1) Sample processing:

[0058] Accurately weigh 0.5g of the polydimethylsiloxane emulsion sample to be tested in a polytetrafluoroethylene digestion tank, add 4mL of nitric acid and 4mL of hydrofluoric acid respectively, after microwave digestion (see Table 1 for the digestion conditions), remove the acid on the electric heating plate Rush to 1~2mL of the remaining liquid at 140°C, transfer to a 25mL plastic volumetric flask, dilute with ultrapure water and shake well for testing.

[0059] (2) Solution preparation: the method is the same as (2) in Example 1.

[0060] (3) Measurement by graphite furnace atomic absorption spectrometer: the method is the same as (3) in Example 1.

[0061] The method verification of the present invention

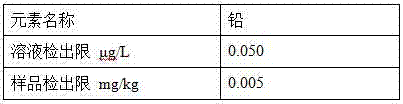

[0062] 1, detection limit: with embodiment 1.

[0063] 2. Repeatability:

[0064] For the polydimethylsiloxane emulsion sample, measure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com