Diffusion low surface concentration efficiency enhancing technology

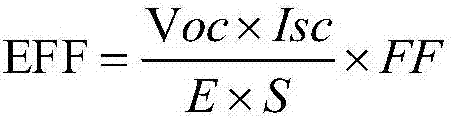

A low-surface, high-concentration technology, applied in sustainable manufacturing/processing, photovoltaic power generation, electrical components, etc., can solve the problems of silicon wafers prone to high temperature, accelerated carrier recombination, electrical loss, etc., to reduce surface recombination, The effect of shortening the oxidation time and reducing the obstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Step 1) Loading and feeding: put the cleaned and dried silicon wafers into the quartz boat, and slowly send the quartz boat full of silicon wafers into the diffusion furnace. The time for feeding the wafers is 600s. Access to N 2 The flow is 10000sccm, N 2 -POCl 3 and O 2 is 0 sccm;

[0026] Step 2) heating up: heating the quartz boat, the heating time is 400s, the temperature is raised to 785°C, N 2 The flow rate is adjusted to 8000sccm, N 2 -POCl 3 and O 2 is 0 sccm;

[0027] Step 3) preoxidation: the O that feeds flow is 2000sccm 2 Perform pre-oxidation, the time is 200s, the temperature is 785°C, N 2 The flow rate is 8000sccm, N 2 -POCl 3 The flow rate is 0sccm;

[0028] Step 4) Diffusion for the first time: the temperature in the furnace is raised to 810°C, O 2 The flow rate is adjusted to 600sccm, and N 2 -POCl 3 And the flow rate is 1200sccm, N 2 The flow rate is 10000sccm, and the diffusion time is 600s;

[0029] Step 5) Advance for the first ti...

Embodiment 2

[0035] Step 1) is the same as embodiment 1;

[0036] Step 2) heating up: heating the quartz boat, the heating time is 400s, the temperature is raised to 775°C, N 2 The flow rate is adjusted to 8000sccm, N 2 -POCl 3 and O 2 is 0 sccm;

[0037] Step 3) preoxidation: the O that feeds flow is 1900sccm 2 Perform pre-oxidation, the time is 180s, the temperature is 775°C, N 2 The flow rate is 8000sccm, N 2 -POCl 3 The flow rate is 0sccm;

[0038] Step 4) Diffusion for the first time: the temperature in the furnace is raised to 805°C, O 2 The flow rate is adjusted to 500sccm, and N 2 -POCl 3 And the flow rate is 1150sccm, N 2 The flow rate is 10000sccm, and the diffusion time is 580s;

[0039] Step 5) Advance for the first time: make the phosphorus on the surface advance into the silicon wafer body, stop feeding O 2 with N 2 -POCl 3 , the furnace temperature is 805°C, N 2 Flow rate is 10000sccm, advance 280s;

[0040] Step 6) The second diffusion: the temperature in t...

Embodiment 3

[0045] Step 1) is the same as embodiment 1;

[0046] Step 2) heating up: heating the quartz boat, the heating time is 400s, the temperature is raised to 795°C, N 2 The flow rate is adjusted to 8000sccm, N 2 -POCl 3 and O 2 is 0 sccm;

[0047] Step 3) preoxidation: the O that feeds flow is 2100sccm 2 Carry out pre-oxidation, the time is 220s, the temperature is 795°C, N 2 The flow rate is 8000sccm, N 2 -POCl 3 The flow rate is 0sccm;

[0048] Step 4) Diffusion for the first time: the temperature in the furnace is raised to 815°C, O 2 The flow rate is adjusted to 700sccm, and the N 2 -POCl 3 And the flow rate is 1250sccm, N 2 The flow rate is 10000sccm, and the diffusion time is 620s;

[0049] Step 5) The first advance: make the phosphorus on the surface advance into the silicon wafer body, stop feeding O 2 with N 2 -POCl 3 , the furnace temperature is 815°C, N 2 Flow rate is 10000sccm, advance 320s;

[0050] Step 6) The second diffusion: the temperature in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com