A kind of sulfonation process and device of alkyl diphenyl ether

A technology for the sulfonation of alkyl diphenyl ethers, which is applied in the field of sulfonation processes and devices for alkyl diphenyl ethers, can solve the problems of restricting the industrialization process of alkyl diphenyl ether sulfonates, increasing the difficulty of separating sulfonate products, Problems such as low content of effective substances in the product can achieve the effect of shortening the residence time, suppressing side reactions, and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

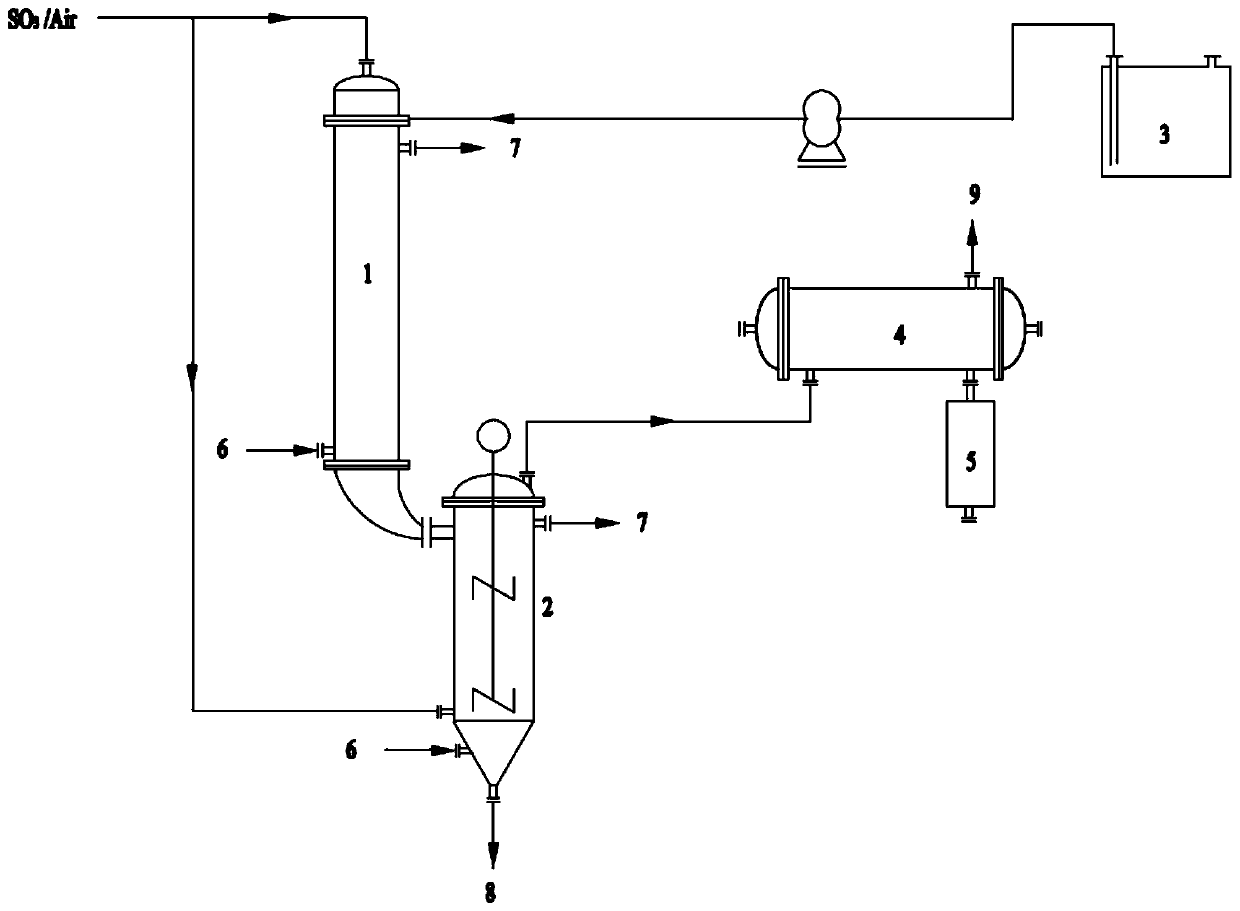

[0020] Realize the object device of the present invention, it comprises membrane type sulfonation reactor 1, tank type sulfonation reactor 2, organic matter / inert solvent storage tank 3, condenser 4 and inert solvent recovery tank 5, it is characterized in that membrane type sulfonation reaction The outlet at the bottom of device 1 is connected to the inlet of tank-type sulfonation reactor 2, the top of membrane-type sulfonation reactor 1 has a mixed gas inlet, and the top of membrane-type sulfonation reactor 1 is connected to organic matter / inert solvent storage tank 3, tank-type The gas outlet of the sulfonation reactor 2 is connected to the condenser 4, the condenser 4 is connected to the inert solvent recovery tank 5, the upper part of the condenser has an exhaust port 9, and the membrane type sulfonation reactor 1 and the tank type sulfonation reactor 2 have cooling Water inlet 6 and cooling water outlet 7.

[0021] Add 500Kg of monododecyl diphenyl ether and 1,2-dichloro...

Embodiment 2

[0023] Add 500Kg of dodecyl diphenyl ether and dichloromethane into the organic matter / inert solvent storage tank 3 according to the ratio of 1:1 (mass ratio) and stir to form an organic mixture, and pump the organic mixture into the membrane sulfur In the reactor 1, while passing SO 3 / air mixture to control the SO in the initial sulfonation reaction process 3 gas concentration (SO 3 The volume ratio of mixed gas) is 2%, gas SO 3 The molar ratio to the organic mixture is 0.8:1, the temperature of the circulating cooling water is 25°C, and the residence time in the membrane sulfonator is 7min. After the preliminary sulfonation reaction, stop feeding SO 3 / air mixture. Put all the products after preliminary sulfonation into the tank type sulfonator 2, and feed SO at the same time 3 / air mixture to control the SO in the sulfonation reaction process 3 gas concentration (SO 3 The volume ratio of mixed gas) is 3%, gas SO 3 The molar ratio with the organic mixture is 2:1, the...

Embodiment 3

[0025] Add 500Kg of isodecyl diphenyl ether and chloroform into the organic matter / inert solvent storage tank 3 according to the ratio of 1:3 (mass ratio) and stir to form an organic mixture, and use a metering pump to pump the organic mixture into the membrane sulfonator 1, while feeding SO 3 / air mixture to control the SO in the initial sulfonation reaction process 3 gas concentration (SO 3The volume ratio of mixed gas) is 4%, gas SO 3 The molar ratio to the organic mixture is 1.5:1, the temperature of the circulating cooling water is 35°C, and the residence time in the membrane sulfonator is 7min. After the preliminary sulfonation reaction, stop feeding SO 3 / air mixture. Put all the products after preliminary sulfonation into the tank type sulfonator 2, and feed SO at the same time 3 / air mixture to control the SO in the sulfonation reaction process 3 gas concentration (SO 3 The volume ratio of mixed gas) is 6%, gas SO 3 The molar ratio to the organic mixture is 2.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com