Method for simultaneously preparing high maltose syrup and protein using potatoes

A high maltose syrup and potato technology, applied in the field of food processing, can solve the problems of high ash content, low protein yield, low protein content and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

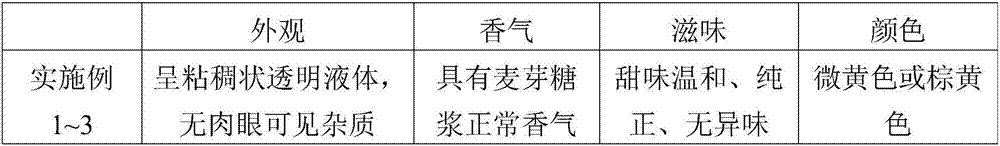

Examples

Embodiment 1

[0036] (1) Raw material selection and pre-treatment: Choose potatoes that have not germinated, rotten and moldy, wash and peel the potatoes with a washing and peeling machine, and then put them into a collection tank containing hot water at 70°C for 30 minutes. After soaking, filter them The watered potatoes are transported to the dicing machine.

[0037] (2) Crush and sieve: Turn on the dicing machine and cut the delivered potatoes into a cross-sectional area of 4-16cm 2 The long strip shape, simultaneously open the two-stage crushing and the inert gas nitrogen in the crushing chamber, monitor the oxygen concentration in real time to adjust the nitrogen flow rate, and transport the diced potatoes to the feed port of the crusher, pulverizer, and sieving machine in sequence, and finally Potato slurry after impurity removal and sieving is obtained.

[0038] (3) Standardization: adjust the potato slurry concentration to 20%, pH value to 4.5, add 0.5‰ of α-amylase (enzyme activ...

Embodiment 2

[0044] (1) Raw material selection and pre-treatment: Choose potatoes that have not germinated, rotten and moldy, wash and peel the potatoes with an all-in-one cleaning and peeling machine, and then put them into a collection tank containing 80°C hot water for 10 minutes. After soaking, filter them The watered potatoes are transported to the dicing machine.

[0045] (2) Crush and sieve: Turn on the dicing machine and cut the delivered potatoes into a cross-sectional area of 4-16cm 2 The long strip shape, simultaneously open the two-stage crushing and the inert gas nitrogen in the crushing chamber, monitor the oxygen concentration in real time to adjust the nitrogen flow rate, and transport the diced potatoes to the feed port of the crusher, pulverizer, and sieving machine in sequence, and finally Potato slurry after impurity removal and sieving is obtained.

[0046] (3) Standardization: adjust the potato slurry concentration to 30%, pH value to 5.5, add 0.2‰ of α-amylase (en...

Embodiment 3

[0052] (1) Raw material selection and pre-treatment: Choose potatoes that have not germinated, rotten and moldy, wash and peel the potatoes with a cleaning and peeling machine, and then put them into a collection tank containing hot water at 75°C for 20 minutes. After soaking, filter them The watered potatoes are transported to the dicing machine.

[0053] (2) Crush and sieve: Turn on the dicing machine and cut the delivered potatoes into a cross-sectional area of 4-16cm 2 The long strip shape, simultaneously open the two-stage crushing and the inert gas nitrogen in the crushing chamber, monitor the oxygen concentration in real time to adjust the nitrogen flow rate, and transport the diced potatoes to the feed port of the crusher, pulverizer, and sieving machine in sequence, and finally Potato slurry after impurity removal and sieving is obtained.

[0054] (3) Standardization: adjust the potato slurry concentration to 25%, pH value to 5.0, add 0.3‰ of α-amylase (enzyme acti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com