A kind of special prepolymerized graphene master batch for thermosetting epoxy resin and preparation method

A technology of epoxy resin and graphene, applied in the field of pre-polymerized graphene masterbatch for thermosetting epoxy resin and preparation, can solve the problem that graphene is difficult to disperse, solvent is difficult to remove, and the performance of graphene epoxy resin composite material is not ideal, etc. problem, to achieve the effect of improving strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

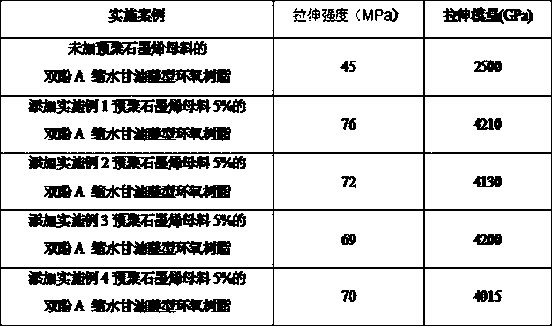

Examples

Embodiment 1

[0030] A special pre-polygraphene masterbatch for thermosetting epoxy resin, made of the following raw materials in parts by weight: 50 parts of graphene, 1 part of surfactant sodium lauryl alcohol polyoxyethylene ether sulfate, bisphenol A type 20 parts of epoxy resin monomer, 1 part of catalyst triphenyl phosphate, 50 parts of organic solvent methyl ethyl ketone, 1 part of latent curing agent boron trinitride ethylamine.

[0031] A kind of preparation method of special pre-polygraphene masterbatch of thermosetting epoxy resin, comprises the following steps:

[0032] (1) Mix graphene and organic solvent evenly, then add surfactant, and ultrasonically disperse for 30-120 minutes to obtain a mixed system;

[0033] (2) Add epoxy resin monomer to the mixing system in step (1), stir and heat up to 70~90°C, add catalyst in 2 times, stir at a uniform speed and dropwise add lye with a concentration of 10%-30%, so that Epoxy resin monomers are pre-polymerized and coated with graphene...

Embodiment 2

[0036] A special pre-polymerized graphene masterbatch for thermosetting epoxy resin, which is made of the following raw materials in parts by weight: 20 parts of redox graphene, 3 parts of surfactant sodium lauryl sulfate, bisphenol F type epoxy resin 40 parts of monomer, 1 part of catalyst tetramethylammonium bromide, 40 parts of organic solvent toluene, 0.5 part of latent curing agent dicyandiamide.

[0037] A kind of preparation method of special pre-polygraphene masterbatch of thermosetting epoxy resin, comprises the following steps:

[0038] (1) Mix graphene and organic solvent evenly, then add surfactant, and ultrasonically disperse for 30-120 minutes to obtain a mixed system;

[0039] (2) Add epoxy resin monomer to the mixing system in step (1), stir and heat up to 70~90°C, add catalyst in 3 times, stir at a constant speed and dropwise add lye with a concentration of 10%-30%, so that Epoxy resin monomers are pre-polymerized and coated with graphene to form a capsule stru...

Embodiment 3

[0042] A special pre-polymerized graphene masterbatch for thermosetting epoxy resin, made by weight of the following raw materials: 50 parts of graphene, 3 parts of surfactant triethanolamine lauryl sulfate, 100 parts of monomer of novolac epoxy resin, The catalyst comprises 2 parts of cetyltrimethylammonium bromide, 100 parts of organic solvent polyethylene glycol, and 1 part of latent curing agent boron trimethylnitride ethylamine.

[0043] A kind of preparation method of special pre-polygraphene masterbatch of thermosetting epoxy resin, comprises the following steps:

[0044] (1) Mix graphene and organic solvent evenly, then add surfactant, and ultrasonically disperse for 30-120 minutes to obtain a mixed system;

[0045] (2) Add epoxy resin monomer to the mixing system in step (1), stir and heat up to 70~90°C, add catalyst in 4 times, stir at a constant speed and dropwise add lye with a concentration of 10%-30%, so that Epoxy resin monomers are pre-polymerized and coated w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com