Removal-type pressure-sensitive adhesive and surface protection film

A re-peelable, adhesive technology, applied in the direction of adhesive types, polyurea/polyurethane adhesives, film/sheet adhesives, etc., can solve problems such as pollution, achieve excellent wettability, The effect of excellent punching workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

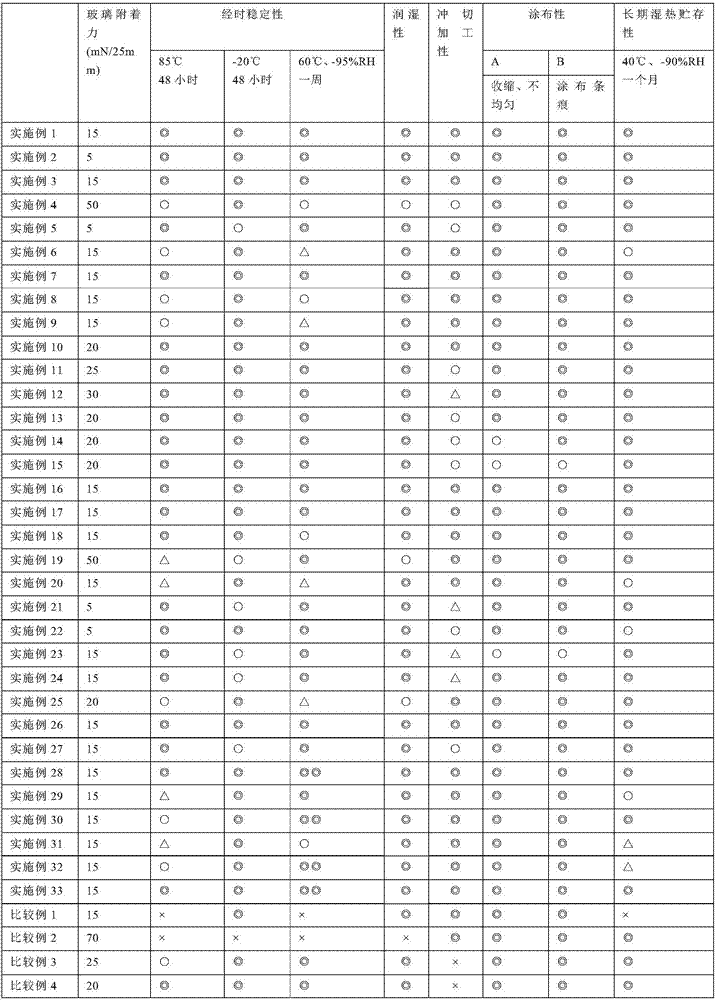

Examples

Embodiment

[0127] Hereinafter, the present invention will be described more specifically by way of examples, but the present invention is not limited to the following examples. Hereinafter, "part" means "mass part" and "%" means "mass%" unless otherwise specified.

[0128] The methods for measuring the weight average molecular weight (Mw) of the resin, the viscosity of the resin, and the hydroxyl value of the resin are as follows.

[0129] (Resin weight average molecular weight (Mw))

[0130] The measurement of the weight average molecular weight was performed under the following conditions. The weight average molecular weight is a polystyrene-equivalent weight average molecular weight determined by gel permeation chromatography (GelPermeation Chromatography, GPC). The measurement conditions are as follows.

[0131] Device: SHIMADZU Prominence (product name, manufactured by Shimadzu Corporation);

[0132] Chromatographic column: three Tosoh TSK-GEL GMHXL (manufactured by Tosoh Corpor...

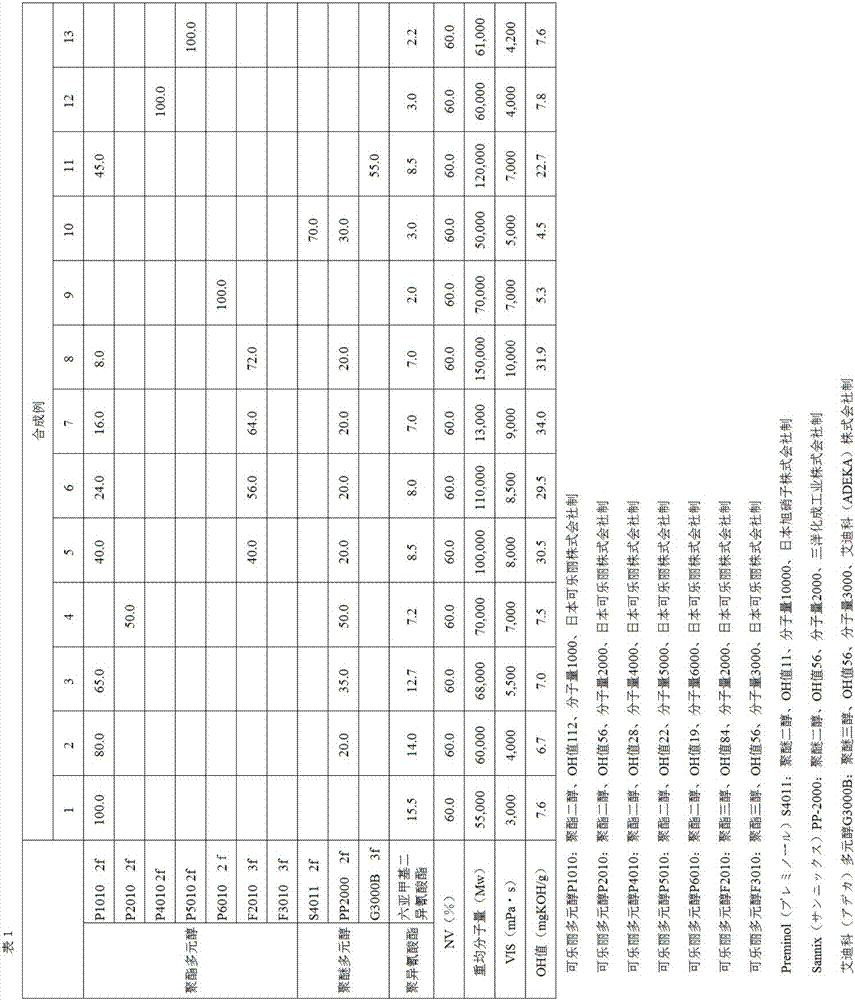

Synthetic example 1

[0150]Under a nitrogen atmosphere, 100 mass parts of polyester polyol P-1010 (difunctional polyester polyol, hydroxyl value 112, number average molecular weight 1000, manufactured by Japan Kuraray Co., Ltd.), 15.5 mass parts of six Methylene diisocyanate (manufactured by Sumitomo Bayer), 77 parts by mass of toluene, 0.25 parts by mass of dibutyltin dilaurate as a catalyst, and 0.01 parts by mass of tin 2-ethylhexanoate were added to the Stirrer, reflux condenser, nitrogen inlet tube, thermometer and dropping funnel in a four-neck flask. The temperature of the flask was gradually raised, and the reaction was carried out at about 90° C. for 2 hours. The reaction was continued while constantly checking whether or not the isocyanate group disappeared by infrared absorption (IR) spectroscopy. After confirming the disappearance of the isocyanate group, it was cooled immediately to complete the reaction. Then, toluene was added so that the non-volatile content (NV) became 60%, and ...

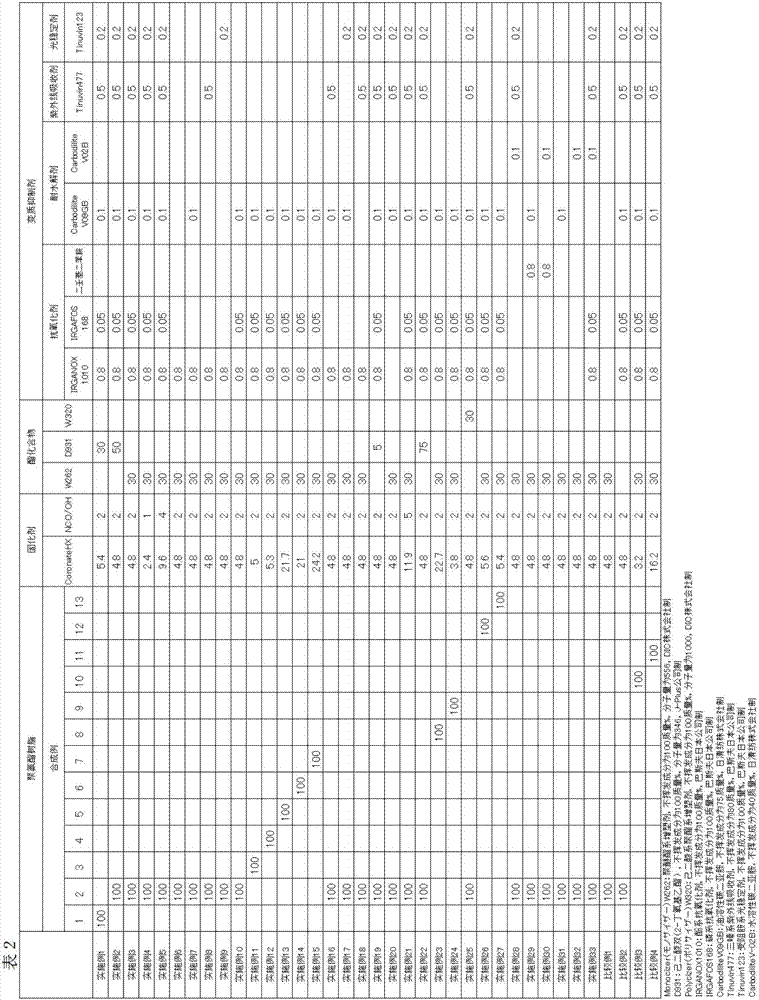

Synthetic example 2~13

[0152] In each of Synthesis Examples 2-13, except having changed the raw material / compounding quantity as shown in Table 1, it carried out similarly to Synthesis Example 1, and obtained the solution of polyurethane resin 2-13. Table 1 describes the solid content (NV) and viscosity (VIS) of the polyurethane resin solution, and the hydroxyl value (OH value) and weight average molecular weight (Mw) of the polyurethane resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com