Ozone oxidation and cracking excitation combined flue gas desulphurization denitration integrated apparatus and method

A technology of ozone oxidation, desulfurization and denitrification, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of high cost and high temperature requirements, and achieve the effects of strong safety, high degree of automation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

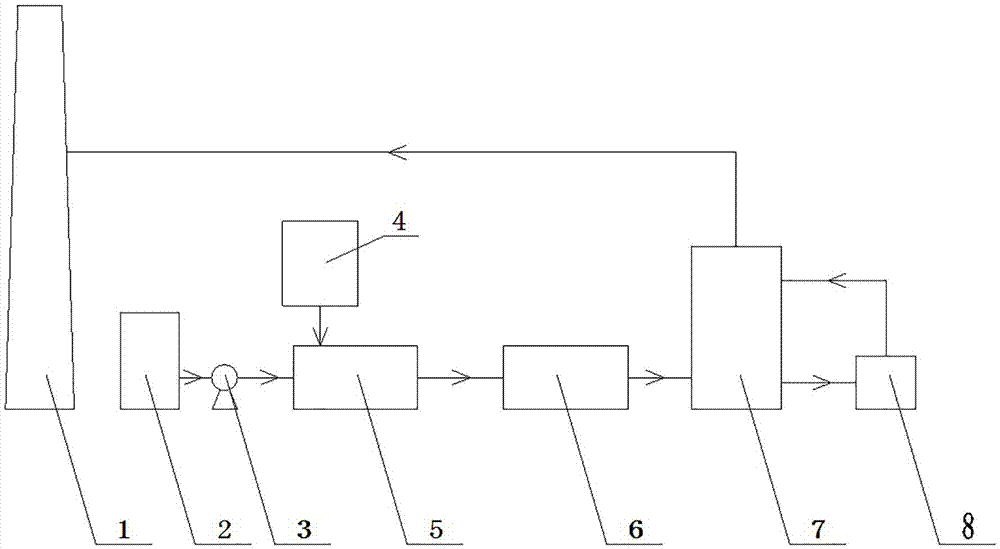

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

[0028] like figure 1 Shown: the present invention comprises chimney 1, ozone source 2, fan 3, boiler 4, oxidation reactor 5, cracking excitation device 6, washing tower 7, sewage treatment device 8; The ozone that ozone source 2 produces is transported to oxidation by fan 3 Reactor 5, the flue gas produced by the boiler 4 is sent to the oxidation reactor 5, and the oxidation reaction occurs in the oxidation reactor 5, and about half of the NO is oxidized to NO 2 , and then the internal energy of the flue gas molecules is increased by the cracking excitation device 6, and the activated flue gas is sent to the scrubber 7, and the scrubbing liquid removes NO, NO 2 Conversion to nitrate and nitrite, SO 2 converted into sulfate; the generated waste water is transported to the sewage treatment device 8 for treatment, the alkaline circulating liquid is returned to the washi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com