Ru-Fe-Cu-La-Ti composite catalytic wet oxidation treatment method

A technology for catalytic wet oxidation and treatment methods, which is applied in the fields of oxidized water/sewage treatment, chemical instruments and methods, chemical elements of heterogeneous catalysts, etc., can solve problems such as poor selectivity, loss, catalyst deactivation, etc. High performance, excellent mechanical strength and wear resistance, simple and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

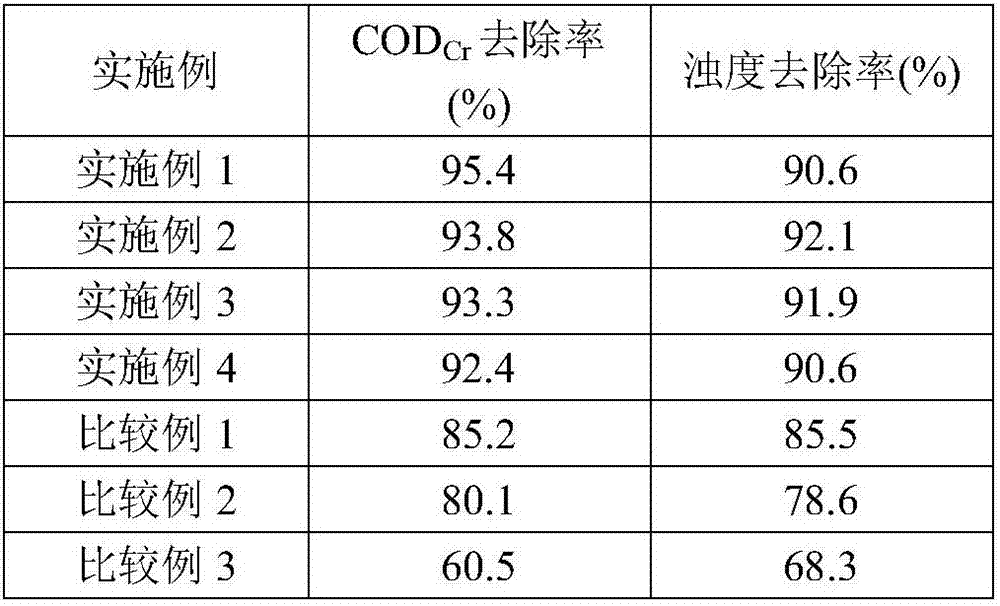

Examples

Embodiment 1

[0042] A preparation method of a Ru-Fe-Cu-La-Ti composite catalytic wet oxidation catalyst, comprising the steps of:

[0043] 1) Pretreatment of the carrier

[0044] (1) 100 meshes of gac 100g are treated with aspartic acid 20g and beaten as carrier core;

[0045] (2) adding activated carbon after aspartic acid treatment in the gelling process of amorphous silica-alumina;

[0046] (3) The amino acid is decomposed and carbonized by roasting, and the amorphous silicon-alumina is promoted to tightly wrap the activated carbon.

[0047] 2) Preparation of impregnating liquid: the selected components are configured into 70 parts by weight of impregnating liquid; the Ru(OH) 3 , Fe 2 (SO 4 ) 3 、CuSO 4 , LaCl 3 ·6H 2 O, TiO 2 , Silica sol are respectively 2g, 4g, 3g, 5g, 3g, 8g dissolved in 45g distilled water according to the quality, then drop dilute nitric acid to make Ru(OH) 3 Dissolve completely and prepare impregnating solution;

[0048] 3) Impregnation: Put 30 parts by...

Embodiment 2

[0052] A preparation method of a Ru-Fe-Cu-La-Ti composite catalytic wet oxidation catalyst, comprising the steps of:

[0053] 1) Pretreatment of the carrier

[0054] (1) 100 meshes of gac 100g are treated with aspartic acid 22g and beaten, as the carrier core;

[0055] (2) adding activated carbon after aspartic acid treatment in the gelling process of amorphous silica-alumina;

[0056] (3) The amino acid is decomposed and carbonized by roasting, and the amorphous silicon-alumina is promoted to tightly wrap the activated carbon.

[0057] 2) Preparation of impregnating liquid: the selected components are configured into 70 parts by weight of impregnating liquid; the Ru(OH) 3 , Fe 2 (SO 4 ) 3 、CuSO 4 , LaCl 3 ·6H 2 O, TiO 2 , Silica sol are respectively 4g, 2g, 3g, 4g, 4g, 8g dissolved in 45g distilled water according to the quality, then drop dilute nitric acid to make Ru(OH) 3 Dissolve completely and prepare impregnating solution;

[0058] 3) Impregnation: Put 30 par...

Embodiment 3

[0062] A preparation method of a Ru-Fe-Cu-La-Ti composite catalytic wet oxidation catalyst, comprising the steps of:

[0063] 1) Pretreatment of the carrier

[0064] (1) 100 meshes of gac 100g are treated with aspartic acid 24g and beaten, as the carrier core;

[0065] (2) adding activated carbon after aspartic acid treatment in the gelling process of amorphous silica-alumina;

[0066] (3) The amino acid is decomposed and carbonized by roasting, and the amorphous silicon-alumina is promoted to tightly wrap the activated carbon.

[0067] 2) Preparation of impregnating liquid: the selected components are configured into 70 parts by weight of impregnating liquid; the Ru(OH) 3 , Fe 2 (SO 4 ) 3 、CuSO 4 , LaCl 3 ·6H 2 O, TiO 2 , Silica sol are respectively 3g, 3g, 5g, 4g, 3g, 7g dissolved in 45g distilled water according to the quality, then drop dilute nitric acid to make Ru(OH) 3 Dissolve completely and prepare impregnating solution;

[0068] 3) Impregnation: Put 30 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com