Pusher of discharging cooler for producing potassium sulphate chemical fertilizer by using Mannheim furnace

A Mannheim furnace and feeder technology, applied in potash fertilizers, inorganic fertilizers, treatment of discharged materials, etc., can solve the problems of unclear corrosion mechanism, increase production cost, feeder corrosion, etc., and improve electrochemical resistance. Corrosion and resistance to physical abrasion, improved service life, extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

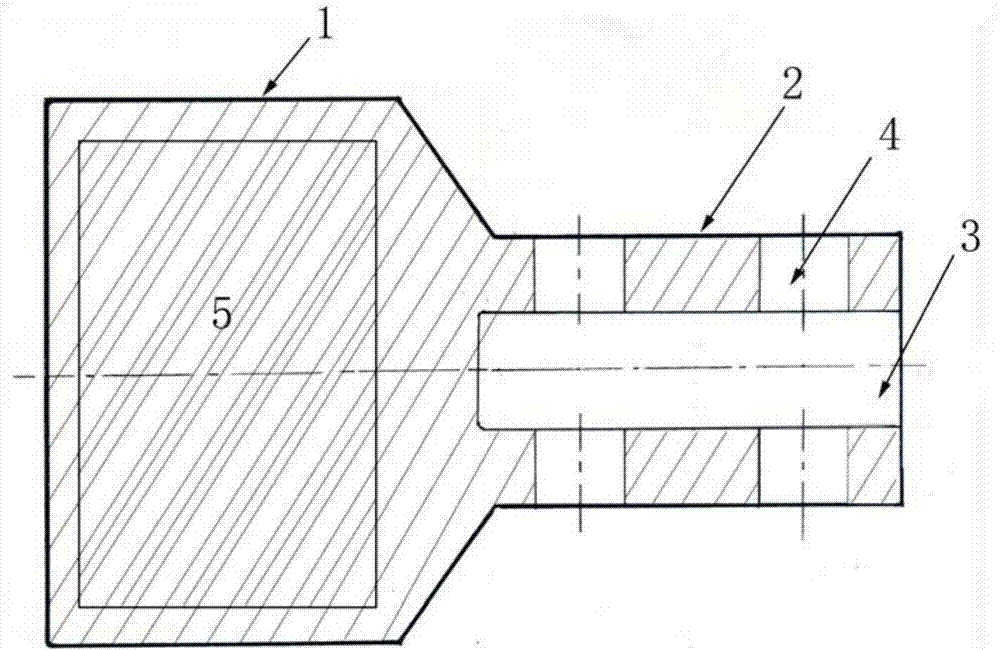

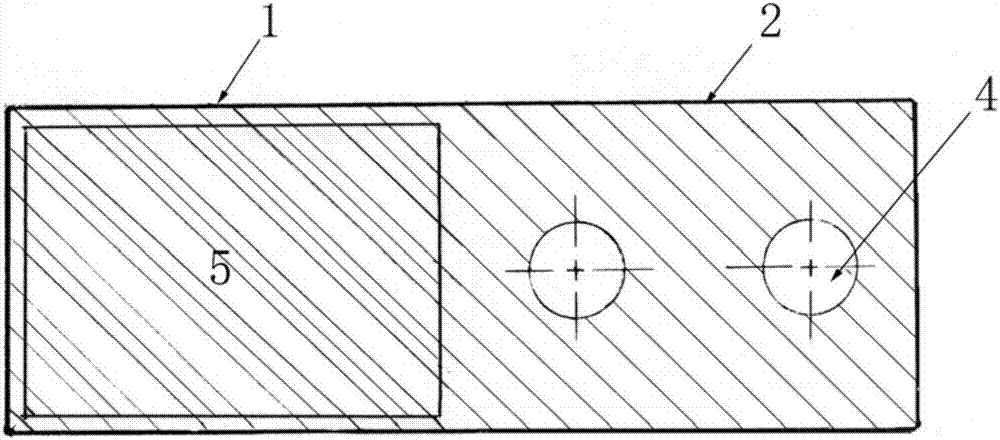

[0031] The present invention is described in detail below in conjunction with accompanying drawing and embodiment.

[0032] The present invention is the pusher of the discharge cooler for the production of potassium sulfate chemical fertilizer in Mannheim furnace, and its use process is: prepare potassium sulfate chemical fertilizer in Mannheim furnace, potassium sulfate is sent into after Mannheim furnace outlet Cooling in the discharge cooler, the potassium sulfate is pushed out by the pusher in the discharge cooler, and then sent out by the conveyor belt for crushing and packaging, which becomes the finished product of potassium sulfate.

[0033] The preparation process of the pusher of the present invention is as follows: according to the design drawing, according to its shape and size, at first make a silicate ceramic workpiece (silicon carbide ceramic block) that can meet the performance of the design technical index, and cast it The intact casting is cast in corrosion-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com