Graphene material and preparation method, and saggar used for graphene preparation

A technology of graphene and saggers, which is applied in the field of preparing graphene saggers, graphene materials and their preparation, can solve the problems of detrimental battery performance, large number of layers, and low graphene output, so as to achieve convenient collection of products, The effect of high preparation efficiency and high yield

Active Publication Date: 2017-08-29

乌兰察布市大盛石墨新材料股份有限公司

View PDF5 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, graphene produced by these methods has defects

For example, using the chemical redox method, although the thickness of graphene is small and the single-layer rate is high, it will cause great damage to graphene during the oxidation process, resulting in voids and the introduction of other functional groups, a large amount of sulfur, and iron-cobalt. Metal impurities such as nickel and manganese greatly affect the conductivity of graphene, resulting in damage to the performance of the battery when it is subsequently applied to the battery

Using the mechanical exfoliation method, although the electrical conductivity of graphene is high, there are disadvantages of thicker graphene and more layers, and the biggest problem of this method is that the raw materials used are flake graphite, expandable graphite or expanded worms. Graphite, when physically and mechanically stripped by liquid or gas methods, the raw material contains a large amount of sulfur and residual impurities such as iron, cobalt, nickel, manganese, potassium and calcium. The content of impurities greatly exceeds the standard, which will damage the battery. performance

Using CVD vapor deposition method, although the obtained graphene has the characteristics of thin single layer or double layer thickness and high electrical conductivity, but due to the need to use a substrate with a large amount of metallic nickel, the substrate needs to be dissolved and stripped. As a result, the output of graphene is extremely low and cannot be used for large-scale ton-level applications

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment (1

[0064] (1) graphite raw material is provided, and described graphite raw material is graphite ore through purification, pulverization;

[0065] (2) Oxidize the graphite raw material, then place the oxidized graphite in a sagger and reduce it in an inert atmosphere at 1000 degrees Celsius to 1050 degrees Celsius to obtain a graphene material, wherein the material of the sagger is high density graphite.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Login to View More

Abstract

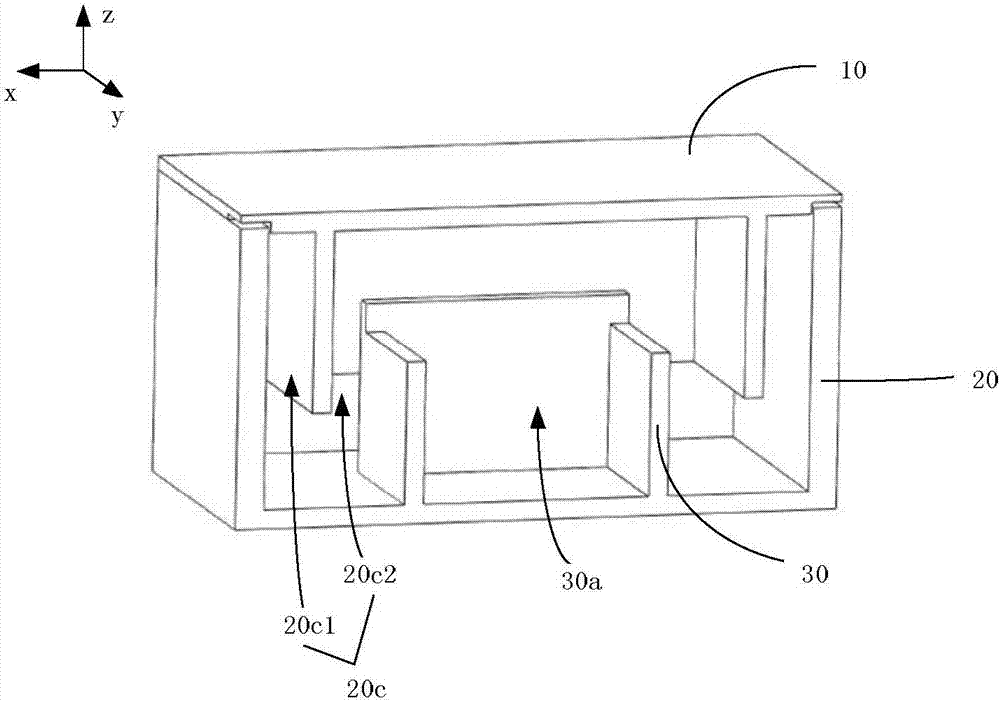

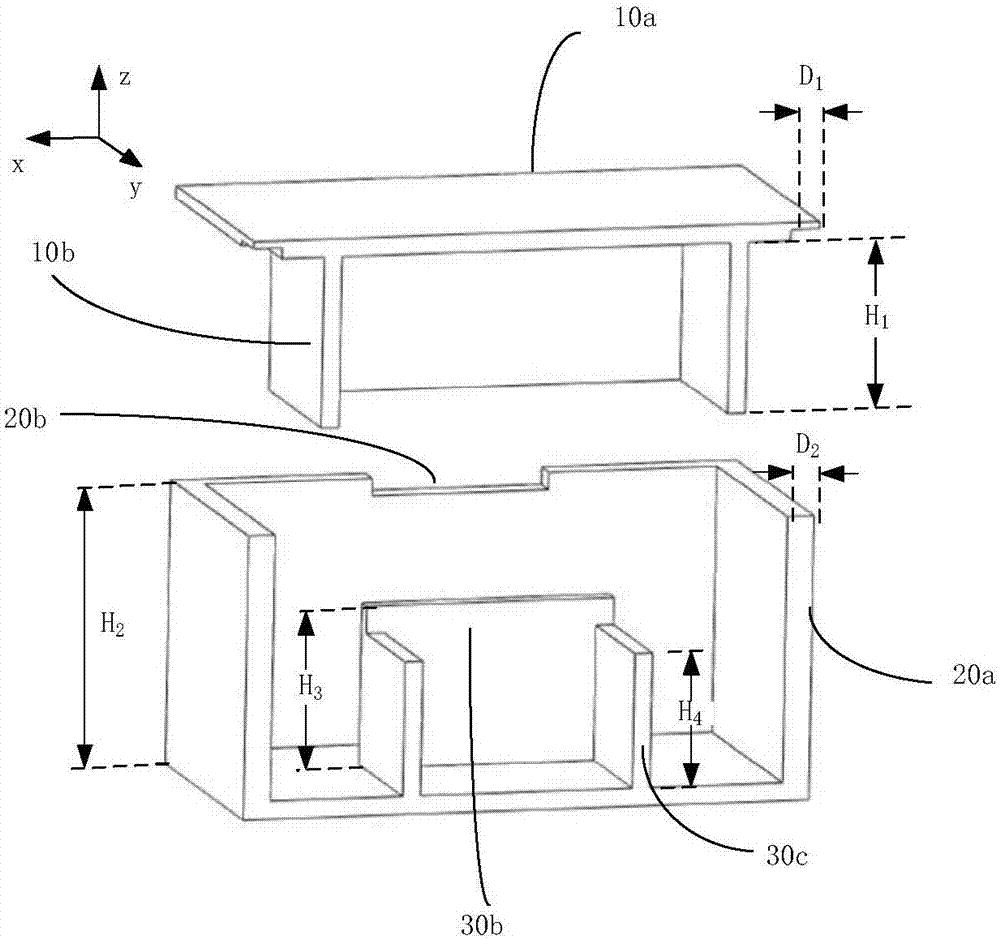

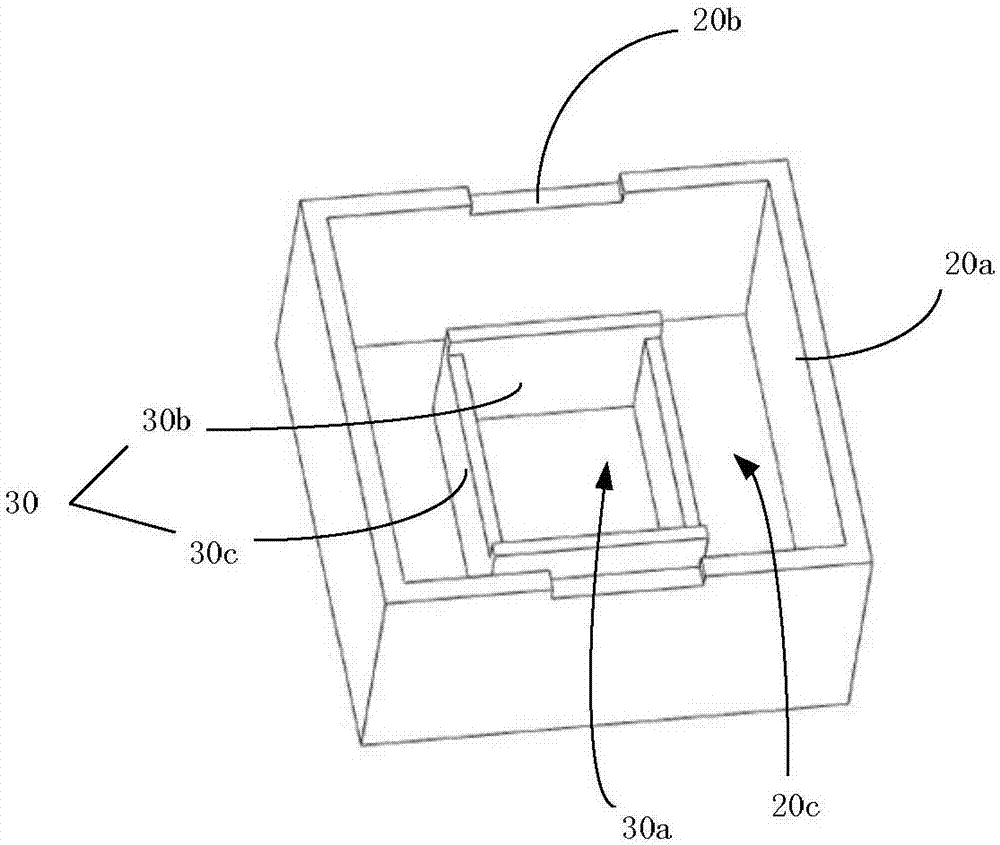

The invention relates to a saggar used for graphene preparation. A material of the saggar is high-density graphite, the saggar comprises a saggar main body and a saggar cover, the top of the saggar main body is opened, the top of the saggar main body is covered by the saggar cover, wherein, the saggar main body comprises an external saggar wall body and an external cavity formed by the external saggar wall body, a gap is arranged on the external saggar wall body, so that the external cavity is communicated with the outside part; an internal saggar is arranged in the saggar main body, the internal comprises an internal saggar wall body and an internal cavity formed by the internal saggar wall body, and the external cavity is communicated with the internal cavity. The invention also provides a method for preparing a graphene material by using the saggar and the graphene material.

Description

technical field [0001] The invention relates to a graphene material, in particular to a sagger for preparing graphene, a graphene material and a preparation method thereof. Background technique [0002] Due to the development of new energy technology, especially electric vehicle technology, there is a huge demand for high-performance power batteries with high capacity and high power density. As a two-dimensional nanomaterial with high conductivity, graphene is considered to be one of the key materials for high-performance conductive agents for power batteries. [0003] Existing methods for preparing graphene include chemical oxidation-reduction methods, mechanical exfoliation methods, CVD vapor deposition methods, and the like. However, the graphene produced by these methods has defects. For example, using the chemical redox method, although the thickness of graphene is small and the single-layer rate is high, it will cause great damage to graphene during the oxidation pro...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C01B32/192H01M4/62

CPCH01M4/625C01B2204/30C01B2204/22C01P2002/72C01P2004/04C01P2002/82Y02E60/10

Inventor 安军伟

Owner 乌兰察布市大盛石墨新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com