A low-pressure ammonia synthesis process for co-production of methanol

A technology of ammonia synthesis and ammonia synthesis tower, which is applied in the field of ammonia synthesis, can solve the problems of low utilization rate of nitrogen and hydrogen, low net value of exported ammonia, etc., achieve the effect of reducing energy consumption, increasing the net value of exported ammonia, and ensuring the smooth operation of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

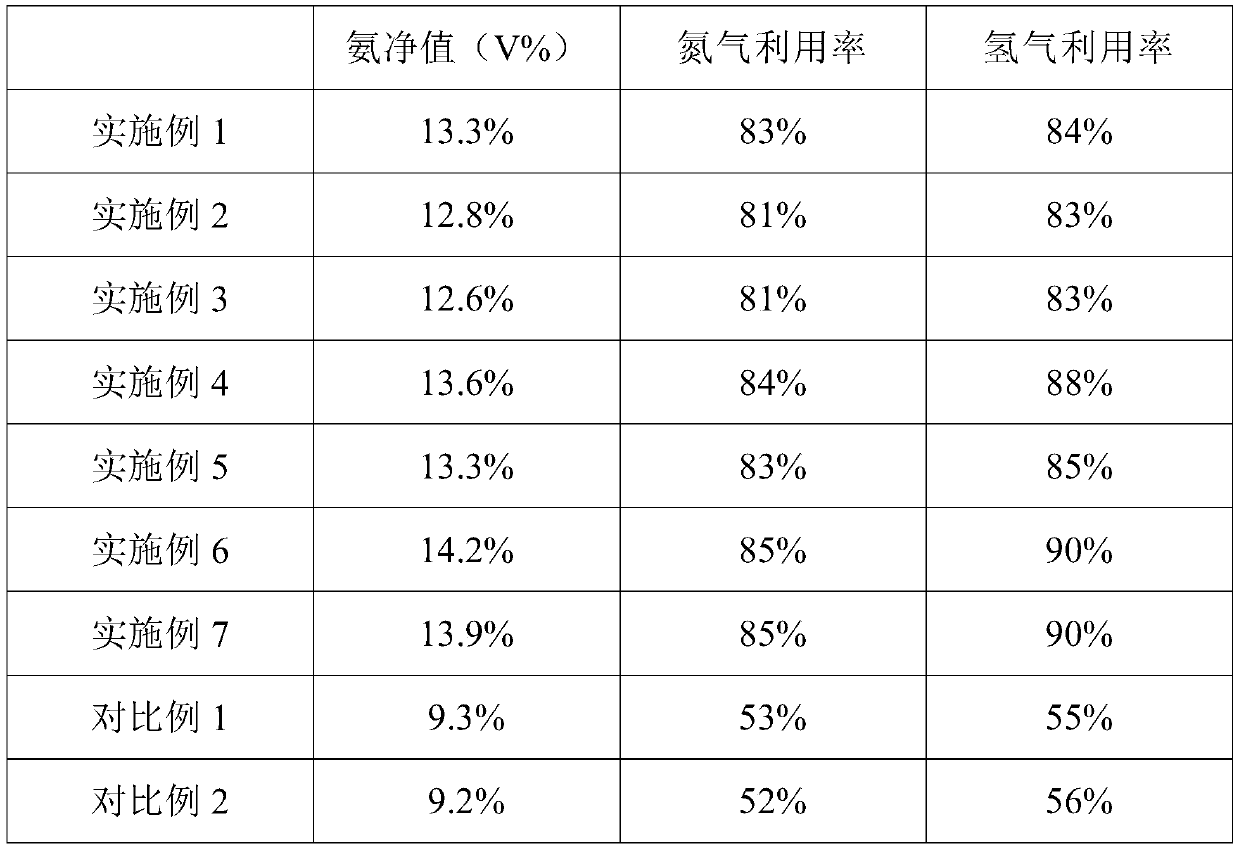

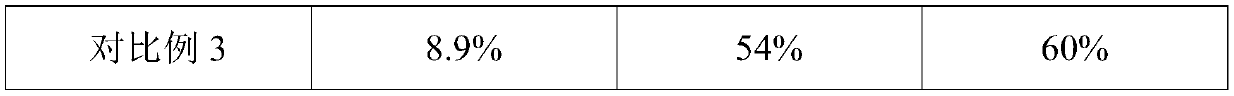

Embodiment 1

[0058] The present embodiment provides a low-pressure ammonia synthesis process for the co-production of methanol, comprising the following steps:

[0059] 1) Carry out cryogenic air separation to air to obtain nitrogen and oxygen, and the oxygen and natural gas are subjected to pure oxygen autothermal conversion to obtain CO and H 2 The mixed gas; moreover, containing CO and H 2 The mixed gas is passed into the waste heat boiler to recover heat, and high-pressure steam is obtained, which is used to pressurize the raw gas for synthesizing ammonia; then, the CO and H-containing 2 The mixed gas is divided into two streams, one is under the action of a copper-based catalyst to synthesize methanol at 210°C and 6 MPa, the other is separated by electrolysis of water to obtain hydrogen; finally, the mixed gas is separated by electrolysis of water, Obtain hydrogen; mix the hydrogen and nitrogen to form synthetic ammonia raw material gas, wherein S2 <10ppm, the molar ratio of hydrogen...

Embodiment 2

[0070] The present embodiment provides a low-pressure ammonia synthesis process for the co-production of methanol, comprising the following steps:

[0071] 1) Carry out cryogenic air separation to air to obtain nitrogen and oxygen, and the oxygen and natural gas are subjected to pure oxygen autothermal conversion to obtain CO and H 2 The mixed gas; moreover, containing CO and H 2 The mixed gas is passed into the waste heat boiler to recover heat, and high-pressure steam is obtained, which is used to pressurize the raw gas for synthesizing ammonia; then, the CO and H-containing 2 The mixed gas is divided into two streams, one is under the action of a copper-based catalyst to synthesize methanol at 250°C and 5 MPa, the other is separated by electrolysis of water to obtain hydrogen; finally, the mixed gas is separated by electrolysis of water, Obtain hydrogen; mix the hydrogen and nitrogen to form synthetic ammonia raw material gas, wherein S2 <10ppm, the molar ratio of hydrogen...

Embodiment 3

[0082] The present embodiment provides a low-pressure ammonia synthesis process for the co-production of methanol, comprising the following steps:

[0083] 1) Carry out cryogenic air separation to air to obtain nitrogen and oxygen, and the oxygen and natural gas are subjected to pure oxygen autothermal conversion to obtain CO and H 2 The mixed gas; moreover, containing CO and H 2 The mixed gas is passed into the waste heat boiler to recover heat, and high-pressure steam is obtained, which is used to pressurize the raw gas for synthesizing ammonia; then, the CO and H-containing2 The mixed gas is divided into two streams, one is under the action of copper-based catalyst to synthesize methanol at 230°C and 5.5MPa, and the other is subjected to electrolytic water separation to obtain hydrogen; finally, the electrolytic water separation is carried out on the mixed gas , to obtain hydrogen; the hydrogen and nitrogen are mixed to form synthetic ammonia raw material gas, wherein S2 <1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com