Black water coupling processing apparatus and method

A processing device and black water technology, applied in the field of coal chemical industry, can solve the problems of large consumption of circulating water, fouling of gasification and black water systems, and high difficulty in layout, so as to alleviate clogging and wear problems, reduce cooling water consumption, and avoid The effect of corrosion risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

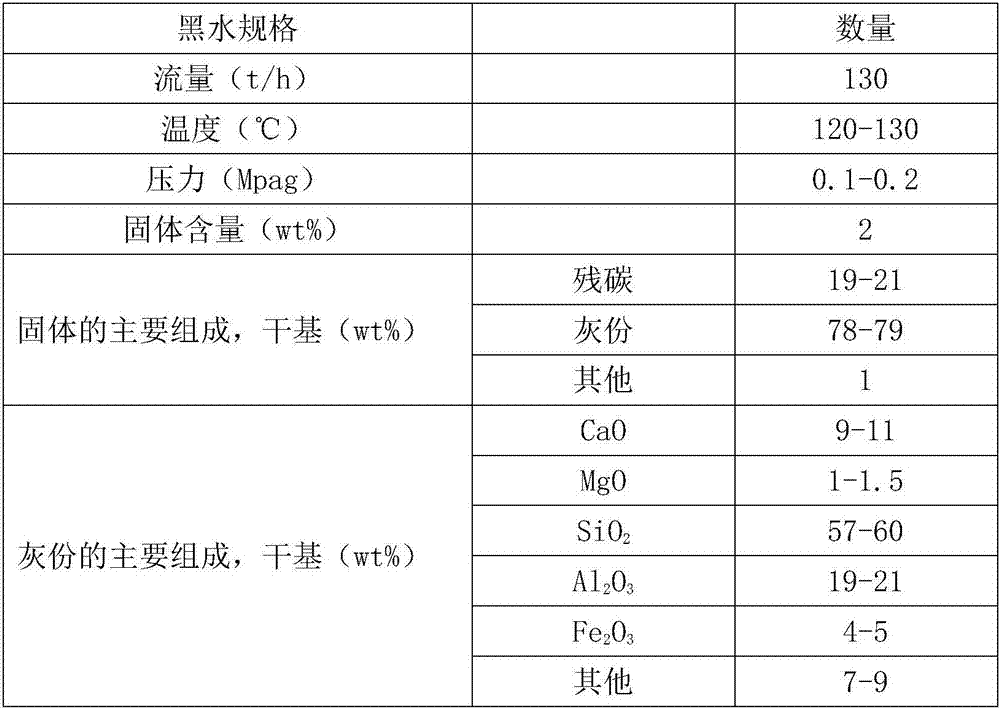

[0024] The black water treated in this example comes from a chilled gasification process with a raw coal single furnace feed rate of 1500t / d and a gasification pressure of 6.5Mpag. The specifications of the black water are shown in Table 1:

[0025] The specification of the black water that table 1 embodiment 1 processes

[0026]

[0027]

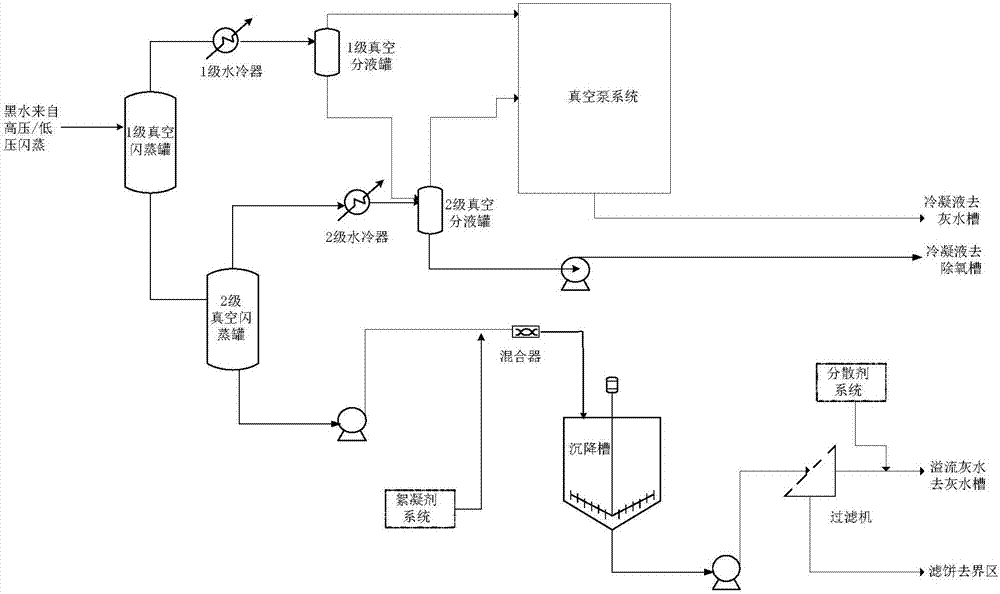

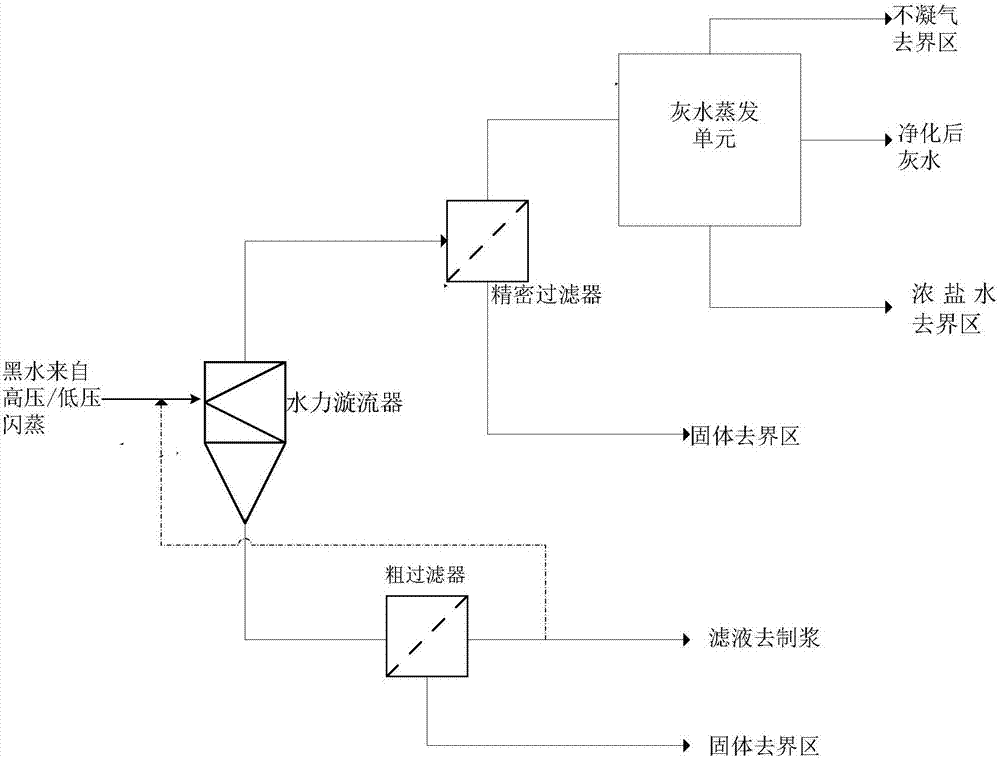

[0028] The black water treatment device mainly includes two process units connected in series: a solid-liquid separation unit and a gray water evaporation unit. Among them, the solid-liquid separation unit mainly includes a hydrocyclone, a coarse filter and a precision filter. The lower part of the hydrocyclone is a conical container.

[0029] Black water treatment process, please refer to figure 2 As shown, the black water from the high pressure / low pressure flash enters the hydrocyclone along the tangential direction at a certain speed, and obtains rotational motion, which generates a large centrifugal force. Under the action of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com