High-heat-stability white light light-emitting glass for borate matrix LED, and preparation method of light-emitting glass

A technology of luminescent glass and thermal stability, applied in luminescent materials, chemical instruments and methods, electrical components, etc., can solve the problems affecting the luminous performance and service life of white LED devices, the influence of the spectral energy distribution of mixed powder, and the accuracy requirements of mixing technology It can achieve the effect of low preparation cost, excellent thermal stability and high transmittance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] According to 84SrO-200B 2 o 3 -2.5Tb 4 o 7 -3Eu 2 o 3 The stoichiometric ratio of 2.5850g SrO, 8.2704gB 2 o 3 , 0.5524g Tb 4 o 7 , 0.3120g Eu 2 o 3 Mix evenly, keep warm at 1250°C for 4 hours, and cool down to room temperature naturally to obtain luminescent glass 84SrO-200B 2 o 3 -2.5Tb 4 o 7 -3Eu 2 o 3 . The luminescent glass emits white light with a chromaticity of (0.359, 0.426).

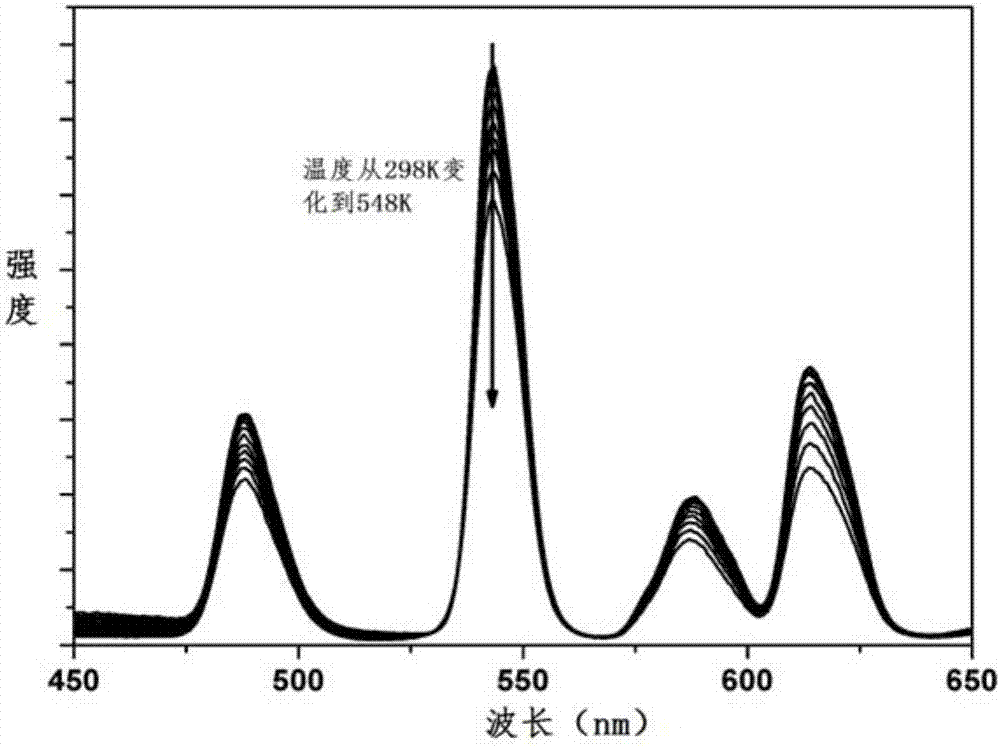

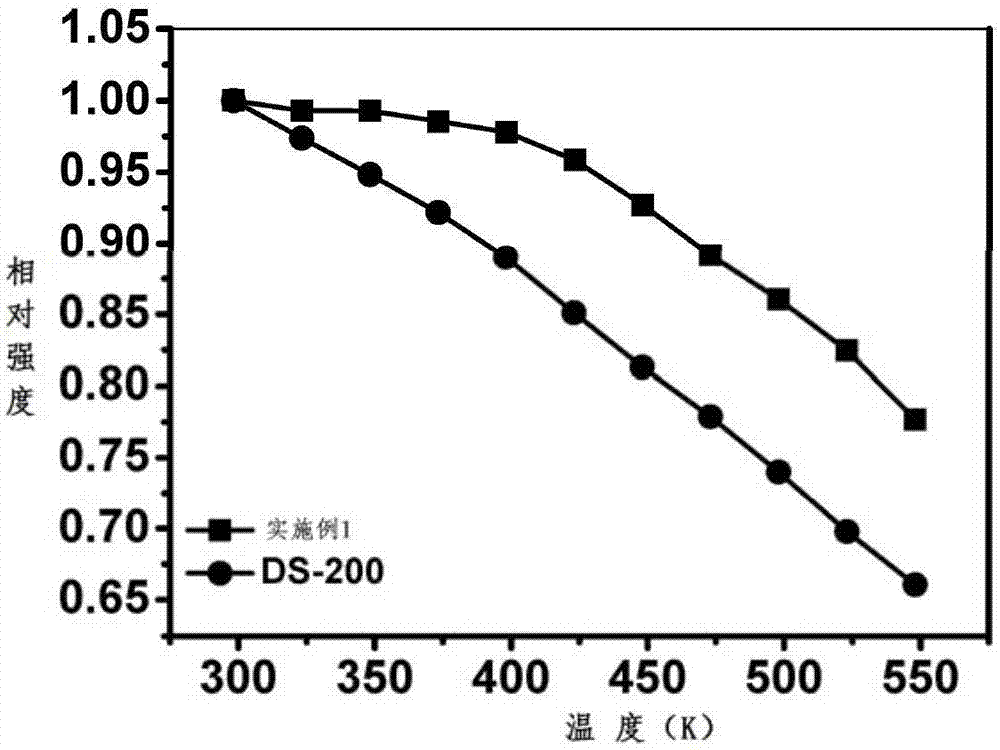

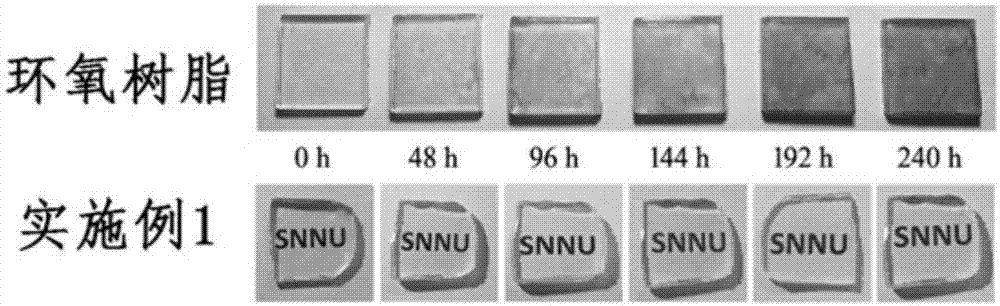

[0020] The inventor tested the thermal stability of the white luminescent glass prepared above, and compared it with the thermal stability of the commercial fluorescent red powder DS-200. The results are shown in figure 1 and figure 2 . From figure 1 and 2 It can be seen that with the increase of temperature, the 84SrO-200B 2 o 3 -2.5Tb 4 o 7 -3Eu 2 o 3 The luminous intensity of the luminescent glass decreases slowly. When the temperature is 548K, the luminous intensity is still 82.5% of the luminous intensity at room temperature, and the thermal stability is b...

Embodiment 2

[0023] According to 88SrO-200B 2 o 3 -2Tb 4 o 7 -2Eu 2 o 3 The stoichiometric ratio of 9.3534g SrO, 8.2704g B 2 o 3 , 0.5524g Tb 4 o 7 , 0.2080g Eu 2 o 3 Mix evenly, keep warm at 1250°C for 4 hours, cool naturally to room temperature, and obtain white light emitting glass 88SrO-200B 2 o 3 -Tb 4 o 7-3Eu 2 o 3 , and its chromaticity is (0.343, 0.430).

Embodiment 3

[0025] According to 86.2SrO-200B 2 o 3 -2.2Tb 4 o 7 -2.5Eu 2 o 3 The stoichiometric ratio of 9.1565g SrO, 8.2704gB 2 o 3 , 0.6076g Tb 4 o 7 , 0.2600g Eu 2 o 3 Mix evenly, keep warm at 1250°C for 4 hours, and cool down to room temperature naturally to obtain white light emitting glass 86.2SrO-200B 2 o 3 -2.2Tb 4 o 7 -2.5Eu 2 o 3 , and its chromaticity is (0.350, 0.429).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com