Method for manufacturing livestock fecaluria fermented liquid fertilizer containing less odor and heavy metal by using effective microorganisms

A technology of heavy metals and microorganisms, applied in the preparation of organic fertilizers, organic fertilizers, liquid fertilizers, etc., can solve problems such as unexpectable effects, achieve excellent removal effects and reduce heavy metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

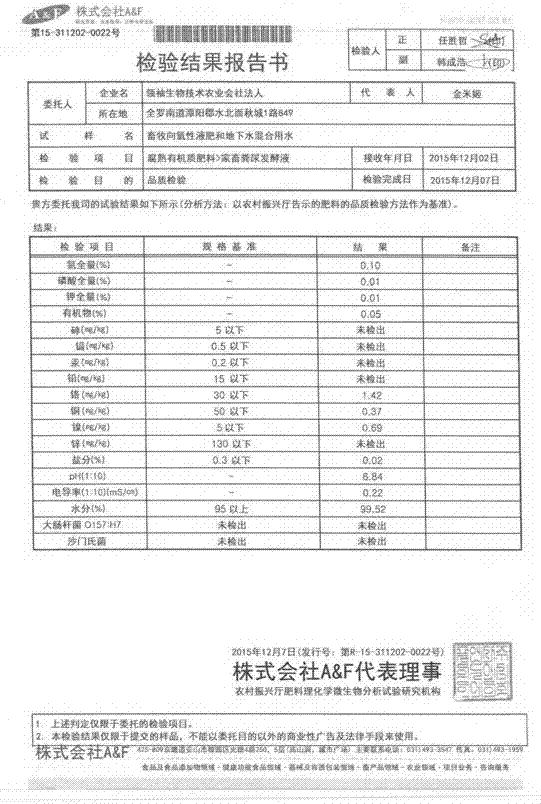

Examples

preparation example Construction

[0018] In order to realize the purpose of the present invention, the present invention provides the preparation method that utilizes the heavy metal content of effective microorganism to obtain the fermented liquid fertilizer that reduces, it is characterized in that, described preparation method comprises the following steps:

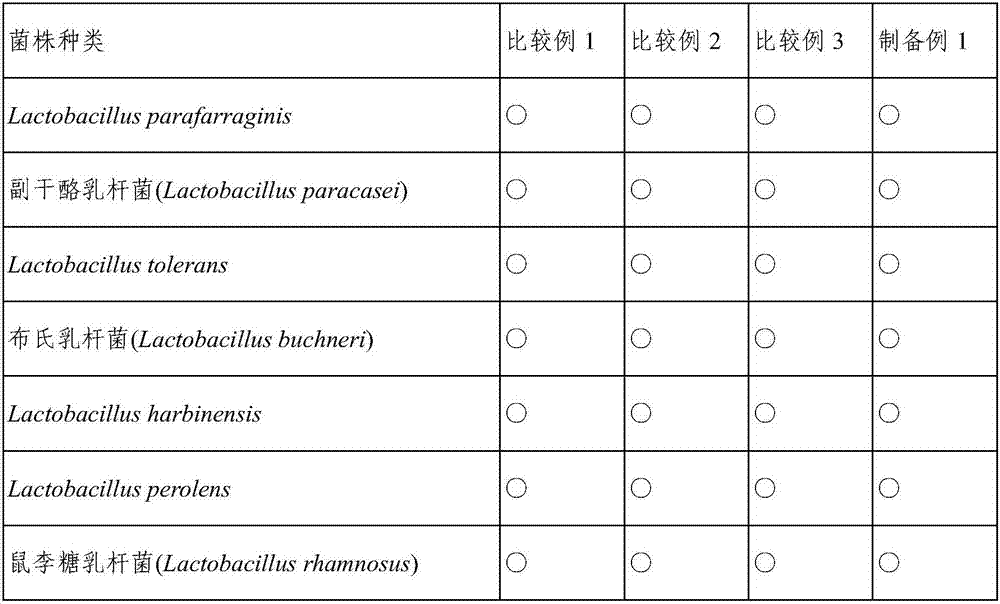

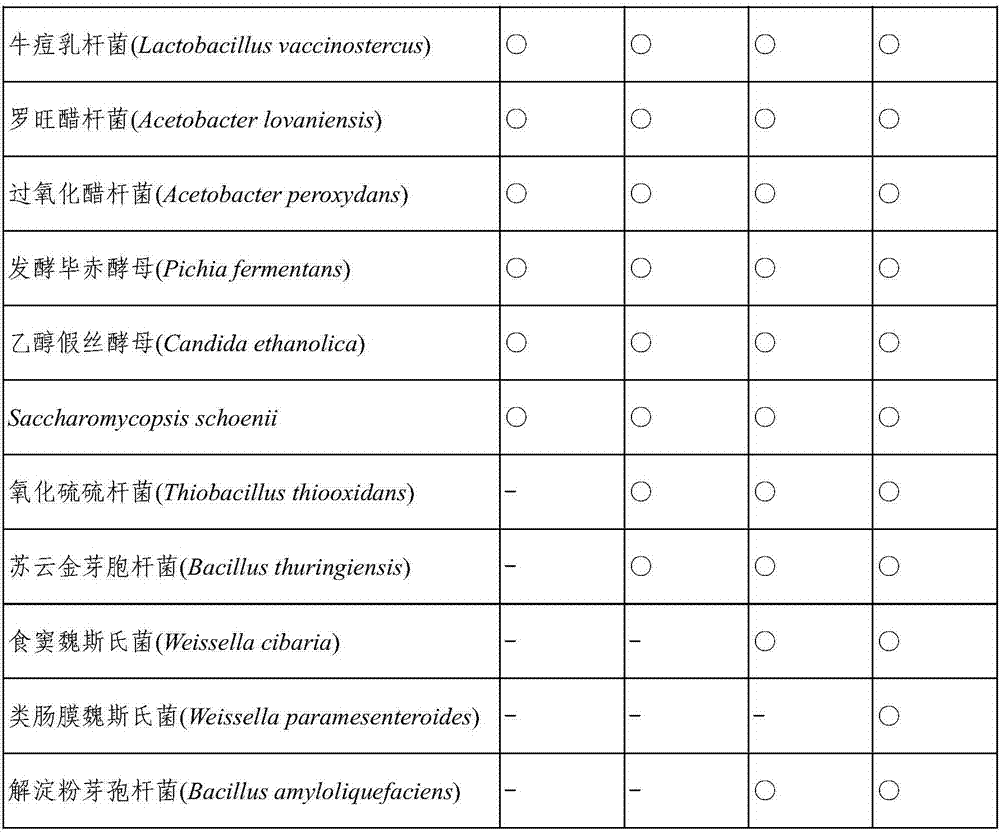

[0019] (a) prepare effective microorganism culture fluid by cultivating effective microorganism mixture, described effective microorganism mixture is made of Lactobacillus parafarraginis, Lactobacillus pa racasei (Lactobacillus pa racasei), Lactobacillus tolerans, Lactobacillus buchneri (Lactobacillus buchneri), Lactobacillus harbinensis, Lactobacillus perolens , Lactobacillus rhamnosus, Lactobacillus vaccinostercus, Acetobacter lovaniensis, Acetobacter peroxydans, Pichia fermentans, Candida ethanol Yeast (Candida ethanolica) and Sacc haromycopsis schoenii;

[0020] (b) adding the effective microbial culture solution and carbon source prepared in the s...

preparation example 1

[0042] Preparation Example 1: Preparation of Effective Microbial Culture Solution

[0043] After mixing effective microorganisms, culture them at a temperature of 25°C for about 120 hours to prepare 1×10 7 The microbial culture fluid of CFU / ml concentration, described effective microorganism is Lactobacillus parafarraginis, Lactobacillus paracasei (Lactobacillus paracasei), Lactobacillus tolerans, Lactobacillus buchneri (Lactobacillus buchneri), Lactobacillus harbinensis, Lactobacillus perolens, Lactobacillus rhamnosus (Lactobacillus rhamnosus), Lactobacillus vaccinostercus, Acetobacter lovaniensis, Acetobacter peroxydans, Pichia fermentans, Candida ethanolica, Saccharomycopsisschoenii, oxidative Thiobacillus thiooxidans, Bacillus thuringiensis, Weissella cibaria, Weissella paramesenteroides and Bacillus amyloliquefaciens.

preparation example 2

[0044] Preparation Example 2: Preparation of fermented liquid fertilizer utilizing effective microbial culture fluid

[0045] (a) In 20 tons of livestock manure, add 20 L of the microbial culture solution prepared in Preparation Example 1 and 15 kg of potato starch at a frequency of once a day, and carry out fermentation at a temperature of 25 to 37° C. for 25 to 35 days and implement solid-liquid separation to obtain a fermented product.

[0046] (b) Add 20 L of the microbial culture solution of Preparation Example 1 and 15 kg of carbon source to 20 tons of livestock manure and ferment for 1 day at a temperature of 25 to 37° C. While adding 20 L of the microbial culture solution of Preparation Example 1, carry out primary fermentation for 5 days, and add 20 L of the microbial culture solution prepared in Preparation Example 1 to the fermented product that has passed through the primary fermentation process once a day , 2 tons of the fermented product prepared in the step (a)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com