Alkaline cleaner and preparation method thereof

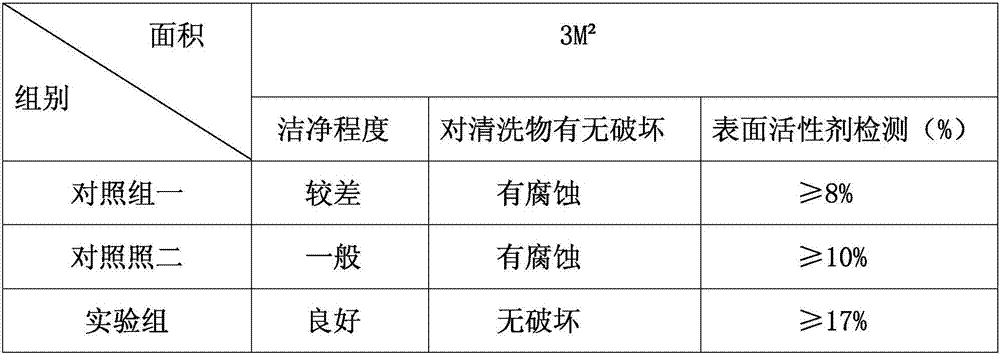

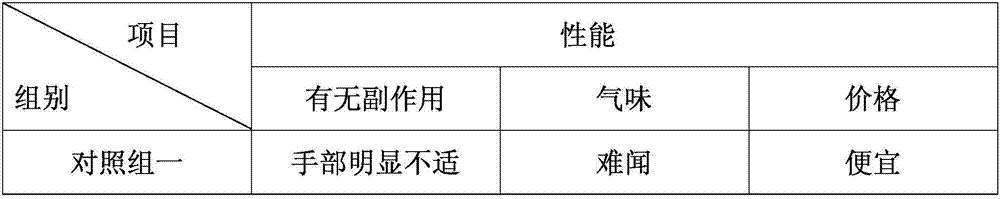

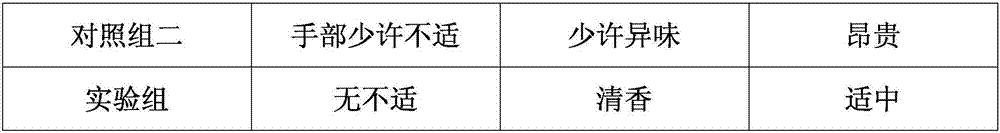

A cleaning agent and alkaline technology, applied in the field of alkaline cleaning agent and its preparation, can solve the problems of high price, damage to the surface of cleaning objects, poor cleaning effect, etc., and achieve the effect of low economic cost and good cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] An alkaline cleaning agent, consisting of fatty alcohol polyoxyethylene ether 50g, coconut oil alkanolamide 100g, oleic acid triethanolamine 40g, monoethanolamine 100g, benzotriazole 20g, disodium EDTA 20g, liquid citric acid 30g, Potassium silicate 18g, alkylbenzenesulfonic acid 15g, tetrapotassium pyrophosphate 27g, sodium metasilicate 14g, diethanolamine 34g, sodium dimethylbenzenesulfonate 9g, sodium hydroxide 12g and water 800g.

[0021] A kind of preparation method of alkaline cleaning agent, comprises the following steps:

[0022] 1) Put 50 g of fatty alcohol polyoxyethylene ether, 100 g of coconut oil alkanolamide and 40 g of triethanolamine oleate in a blender, stir for 5 minutes at a temperature of 20° C., and then pour the liquid into a glass container to obtain the first Mixture, spare;

[0023] 2) Put 100 g of monoethanolamine, 20 g of benzotriazole and 20 g of disodium EDTA in a blender, stir at 30°C for 10 min, then pour the liquid into a glass container...

Embodiment 2

[0030] An alkaline cleaning agent, consisting of fatty alcohol polyoxyethylene ether 80g, coconut oil alkanolamide 80g, oleic acid triethanolamine 20g, monoethanolamine 80g, benzotriazole 10g, EDTA disodium 10g, liquid citric acid 20g, Potassium silicate 16g, alkylbenzenesulfonic acid 14g, tetrapotassium pyrophosphate 25g, sodium metasilicate 13g, diethanolamine 30g, sodium dimethylbenzenesulfonate 7g, sodium hydroxide 11g and water 700g.

[0031] A kind of preparation method of alkaline cleaning agent, comprises the following steps:

[0032] 1) Put 80g of fatty alcohol polyoxyethylene ether, 80g of coconut oil alkanolamide and 20g of triethanolamine oleate in a blender, stir for 5min at 20°C, then pour the liquid into a glass container to prepare the first Mixture, spare;

[0033] 2) Put 80 g of monoethanolamine, 10 g of benzotriazole and 10 g of disodium EDTA in a blender, stir at 30° C. for 10 min, and then pour the liquid into a glass container to prepare the second mixed...

Embodiment 3

[0040]An alkaline cleaning agent, consisting of 65g of fatty alcohol polyoxyethylene ether, 90g of coconut oil alkanolamide, 30g of triethanolamine oleate, 90g of monoethanolamine, 15g of benzotriazole, 15g of disodium EDTA, 25g of liquid citric acid, Potassium silicate 17g, alkylbenzenesulfonic acid 14.5g, tetrapotassium pyrophosphate 26g, sodium metasilicate 13.5g, diethanolamine 32.5g, sodium dimethylbenzenesulfonate 8g, sodium hydroxide 11.5g and water 750g .

[0041] A kind of preparation method of alkaline cleaning agent, comprises the following steps:

[0042] 1) Put 65g of fatty alcohol polyoxyethylene ether, 90g of coconut oil alkanolamide and 30g of triethanolamine oleate in a blender, stir at 20°C for 5min, then pour the liquid into a glass container to prepare the first Mixture, spare;

[0043] 2) Put 90 g of monoethanolamine, 15 g of benzotriazole and 15 g of disodium EDTA in a blender, stir at 30° C. for 10 min, and then pour the liquid into a glass container t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com