Preparation and application of ferrite magnet/pucherite composite material

A technology of composite materials and precursor films, applied in electrolytic coatings, electrodes, electrophoretic plating, etc., can solve problems such as thickness and uniformity quality influence, film thickness, unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

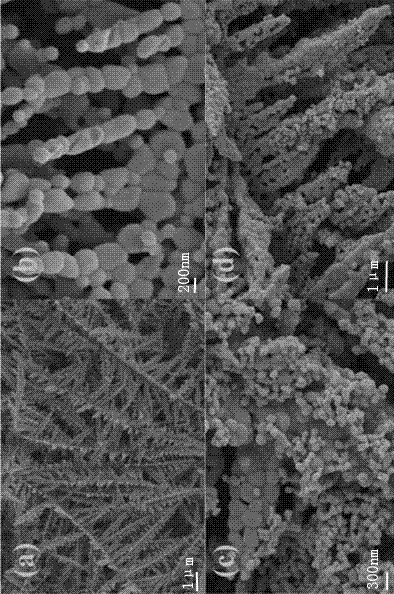

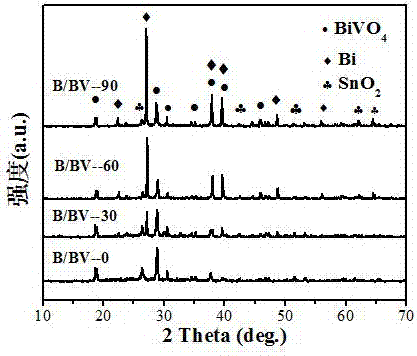

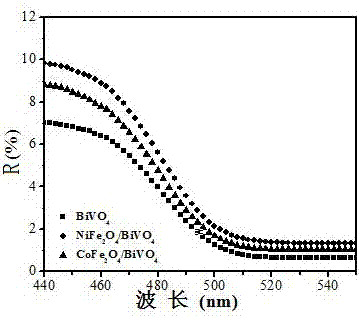

[0032] Example 1, NiFe 2 o 4 / BiVO 4 preparation of

[0033] (1) Preparation of Bi precursor film: The electrolyte was composed of 100mL ethylene glycol and 50mL containing 0.01mol Bi(NO 3 ) 3 ·5H 2 O, 0.03mol Zn (NO 3 ) 2 ·6H 2 O's distilled water composition. Using 1 × 2.5 cm F-doped SnO 2 Coated glass (FTO) conductive substance was used as working electrode, Ag / AgCl (3.5M) was used as reference electrode, and platinum sheet was used as counter electrode. After electrodeposition by chronoamperometry (i-t) at a constant potential of −0.6 V at a scan rate of 50 mV / s for 200 s, the Bi precursor film was completely washed with absolute ethanol and dried in ambient air.

[0034] (2) Leaf structure BiVO 4 Preparation of the film: 0.1 mL of 0.2 mol / L VO(acac)2 in DMSO solution was dropped onto the Bi precursor film prepared above using a syringe, and heated to 450 °C in air (heating rate was 2 °C / min) , sintered for 2 hours; naturally cooled to room temperature and ...

Embodiment 2

[0038] Example 2, CoFe 2 o 4 / BiVO 4 preparation of

[0039] (1) Preparation of Bi precursor film: same as Example 1;

[0040] (2) Leaf structure BiVO 4 The preparation of membrane: with embodiment 1;

[0041] (3) CoFe 2 o 4 Preparation: Co(CH 3 COO) 2 4H 2 O and Fe 2 o 3 Mix in a mortar with a molar ratio of 1:2~3:2, add a small amount of absolute ethanol, grind back and forth continuously for 30~40 minutes, package the mixture in porcelain, and heat at 700~800°C for 6~8 Hours, the remaining product was collected and ground into powder to obtain CoFe 2 o 4 ;

[0042] (4) CoFe 2 o 4 / BiVO 4 Preparation: 20~40mg NiFe 2 o 4 Powder added to contain 5~10mgI 2 50mL of acetone solution, ultrasonic dispersion for 40 minutes to obtain a suspension; BiVO 4 The electrode membrane was inserted into the suspension and connected to the negative pole of the DC power supply, with the FTO glass parallel to the BiVO 4 The electrode is inserted into the suspension and conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com