Dual-layer polarization uncooled infrared detector structure and preparation method thereof

An uncooled infrared and detector technology, used in the manufacture of microstructure devices, microstructure technology, microstructure devices, etc., can solve the problems of complex optical components, complex optical path systems, and difficult design, and achieve obvious contour characteristics and simplification. Optical system, the effect of reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A method for preparing a double-layer polarization uncooled infrared detector structure, comprising the following steps:

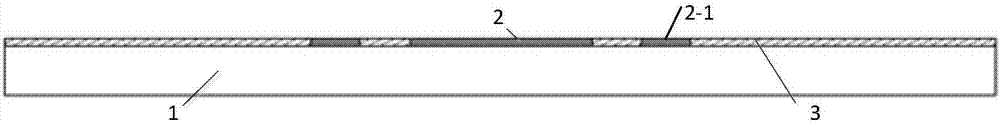

[0063] Step 1: Fabricate a metal reflective layer 2 on a semiconductor base 1 containing a readout circuit, and perform patterning on the metal reflective layer 2, and the patterned metal reflective layer 2 forms several metal blocks 2-1; the metal The block 2-1 is electrically connected to the readout circuit on the semiconductor base 1; then, an insulating dielectric layer 3 is deposited on the patterned metal reflective layer 2, and the insulating dielectric layer 3 is patterned to expose the metal block 2 -1, if figure 1 shown;

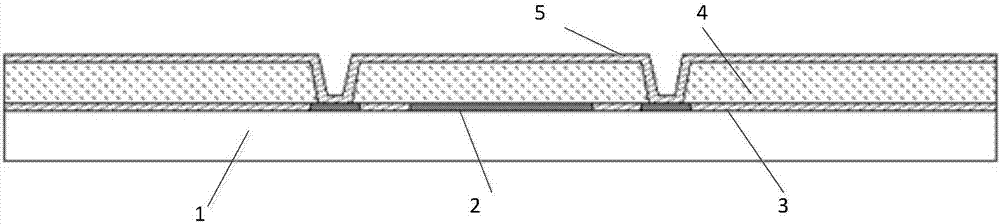

[0064] Step 2: Depositing a first sacrificial layer 4 on the insulating dielectric layer 3, and patterning the first sacrificial layer 4, depositing a first supporting layer 5 on the patterned first sacrificial layer 4, Such as figure 2 shown;

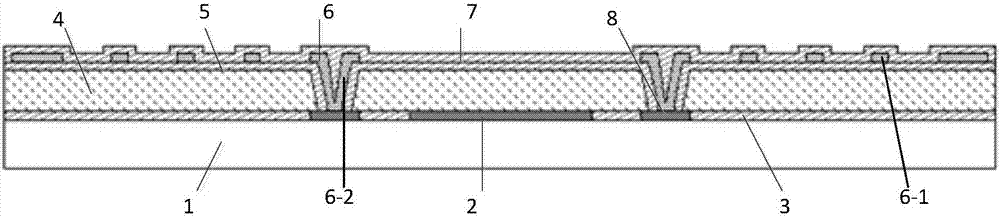

[0065] Step 3: Using photolithography and etching methods, etch away p...

Embodiment 2

[0075] The difference from Example 1 is that when the metal grating structure is prepared in step 10, the photoresist or PI is first spin-coated on the second support layer, and the grating pattern is obtained on the photoresist coating or PI coating by photolithography technology, The grating interval is 10-500nm, then, use physical vapor deposition or sputtering to deposit or sputter a metal film on the photoresist or PI coating that has been photoresisted, and finally, use the stripping process to remove the photoresist or PI coating, and Peel off excess metal film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com