Phenolic resin microspheres as well as preparation method and application thereof

A phenolic resin and microsphere technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problem that the particle size, sphericity and roughness of microspheres are difficult to control, the preparation process of phenolic resin microspheres is cumbersome, and the phenolic resin microspheres are difficult to control. Non-uniform particle size and other problems, to achieve the effect of less energy consumption, high mechanical strength and good sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Weigh 5 mmol of phloroglucinol, 25 mmol of glyoxylic acid and 0.1 mmol of F127 and dissolve them in 100 mL of acetonitrile, ultrasonically dissolve, and then stir at 400 r / min for 30 min at room temperature to self-assemble the monomer and porogen, After stirring, the self-assembled hydrogel was placed in a water bath at 80 °C for 24 h. After the reaction, cool to room temperature, centrifuge at 15,000 r / min for 5 min, wash with deionized water 5 times, and then wash with ethanol 5 times to remove unreacted impurities and porogen F127. Vacuum dry at 40 °C Finally, phenolic resin microspheres were obtained.

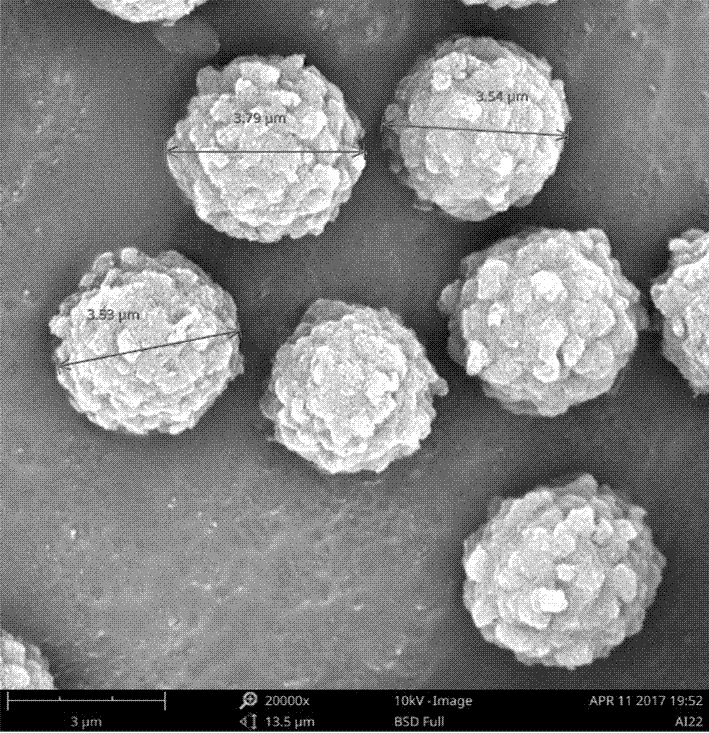

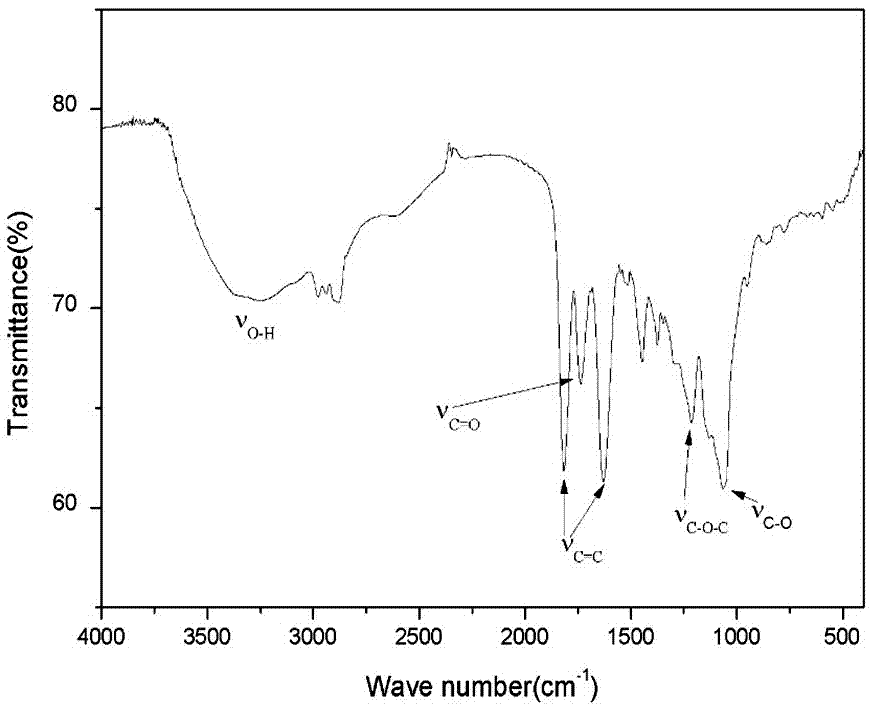

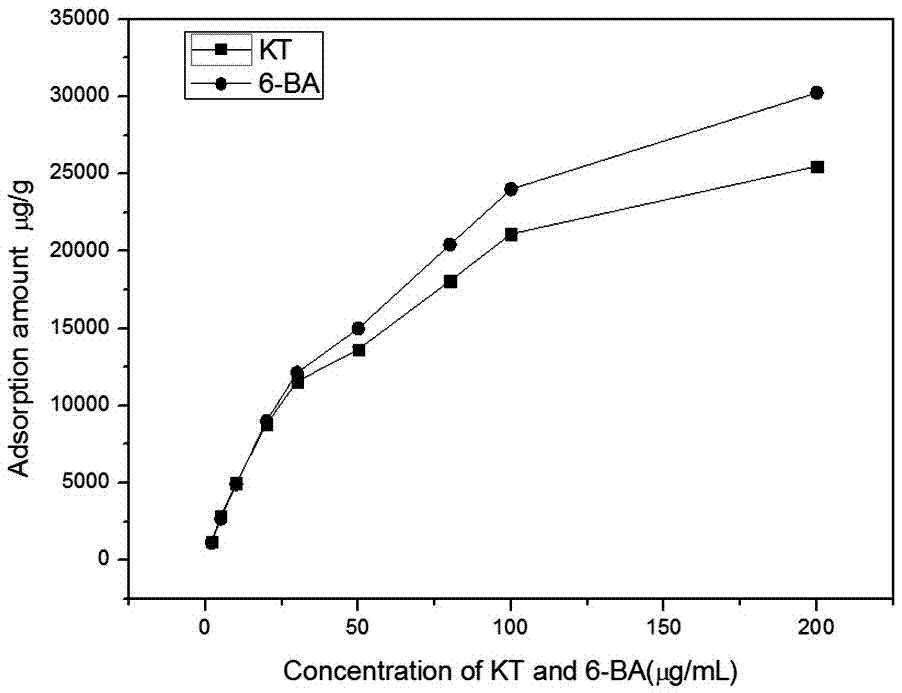

[0039] The obtained phenolic resin microspheres were characterized by SEM, and the obtained results were as follows: figure 1 shown. It can be seen from the figure that the surface of the phenolic resin microspheres is rough, the particle size distribution is uniform, and the particle size is 3.5 μm. The resulting phenolic resin microspheres were characterized by...

Embodiment 2

[0045]Weigh 5 mmol of phloroglucinol and 25 mmol of glyoxylic acid and dissolve them in 100 mL of acetonitrile, ultrasonically dissolve, and then stir at 400 r / min for 30 min at room temperature. ℃ in a water bath for 24 hours. After the reaction, cool down, centrifuge at 15000 r / min for 5 min, wash with deionized water for 5 times, and then wash with ethanol for 5 times to remove unreacted impurities. The phenolic resin microspheres were obtained after vacuum drying at 40 °C.

[0046] The obtained phenolic resin microspheres were characterized by SEM, and the obtained results were as follows: Figure 5 shown. It can be seen from the figure that the surface of the phenolic resin microspheres is smooth, the particle size distribution is uniform, and the particle size is 1 μm.

Embodiment 3

[0048] Weigh 5 mmol of phloroglucinol, 25 mmol of glyoxylic acid and 0.05 mmol of F127 into 100 mL of acetonitrile, ultrasonically dissolve, and then stir at room temperature with mechanical stirring at 400 r / min for 30 min to make the monomer and porogen After stirring, the self-assembled hydrogel was placed in a water bath at 80 °C for 24 h. After the reaction, cool to room temperature, centrifuge at 15000 r / min for 5 min, wash with deionized water for 5 times, then wash with ethanol for 5 times to remove unreacted impurities and porogen F127, and then in The phenolic resin microspheres can be obtained after vacuum drying at 40 °C.

[0049] The obtained phenolic resin microspheres were characterized by SEM, and the obtained results were as follows: Figure 6 shown. It can be seen from the figure that the surface of the phenolic resin microspheres is rough, the particle size distribution is uniform, and the particle size is 4 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com