Ocean-sourced Microbacterium keratanolyticum MCDA02, method for producing enzyme from ocean-sourced Microbacterium keratanolyticum MCDA02, and product

A technology of keratin and microbacteria, applied in the field of microorganisms, can solve the problems of low enzyme production activity, few reports, poor deacetylation effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

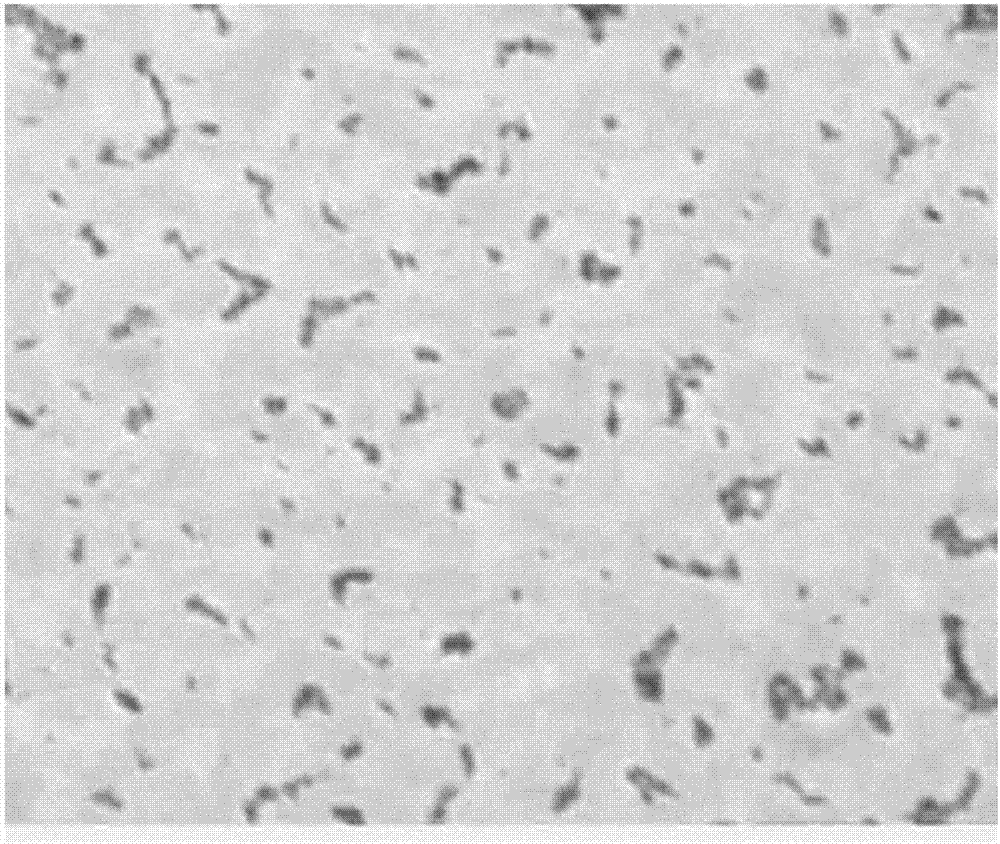

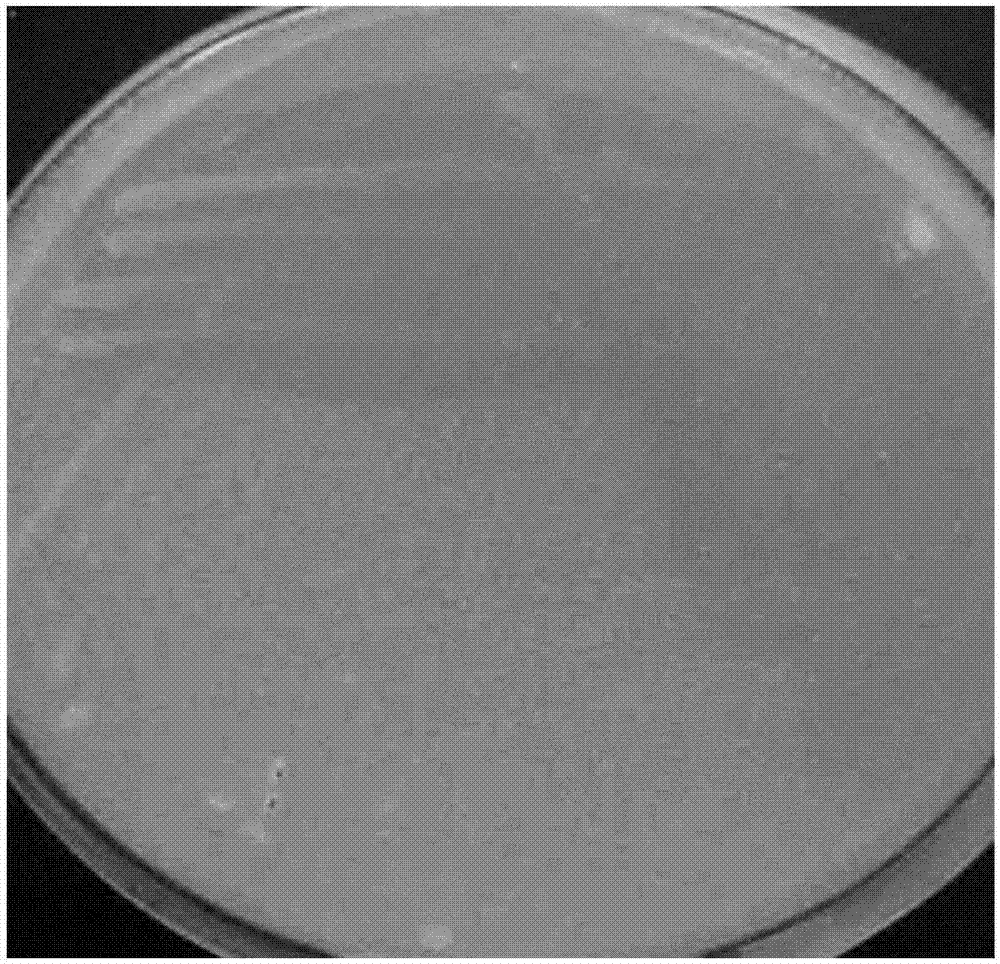

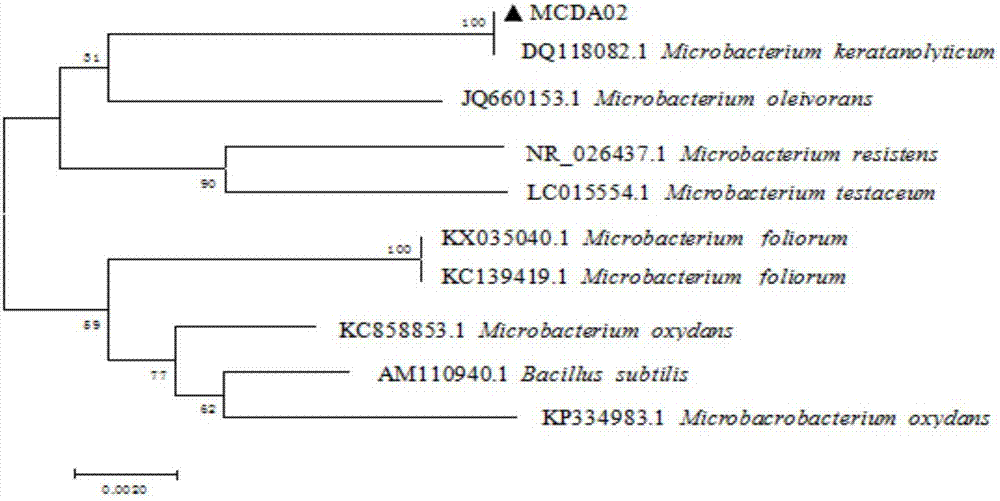

[0081] Example 1, a marine microbacterium keratanolyticum MCDA02 (Microbacterium keratanolyticum) CGMCC NO.13539. The bacterial strain has the following characteristics: the bacterial strain is Gram-negative short bacilli without spores. After the strain was cultured on 2216E solid culture for 48 hours: yellow, translucent, smooth and moist surface, round shape, neat edges, slightly protruding center, easy to pick. A yellow discolouration can be produced on selection media containing colloidal chitin and p-nitro-N-acetanilide. The strain's starch hydrolysis, indole test, hydrogen sulfide production, and arginine decarboxylase tests were all positive, and the citrate utilization, catalase, gelatin liquefaction, VP test, methyl red, glucose fermentation, and nitrate reduction tests were all positive. Negative. The strain grows slowly below 5°C and above 45°C, and the optimum growth temperature is 30°C. The suitable pH range for growth is 6.0-10.0, and the optimal growth pH is...

Embodiment 2

[0082] Example 2, a method for producing chitin deacetylase by fermentation of Microbacterium keratinolyticum MCDA02 as described in Example 1, the steps are as follows: Inoculate the bacterial strain MCDA02 preserved on the 2216E slant into the seed medium, fill the solution Inoculate the seed liquid with 1% inoculation amount in the enzyme-producing medium, and incubate at 20% liquid volume, 180 r / min, and 30°C for 48 hours , centrifuged at 10000r / min for 10min, and the supernatant was obtained as crude chitin deacetylase enzyme. The seed medium is: yeast powder 0.1%, peptone 0.5%, NaCl 1%, prepared from old sea water, pH 7.0; fermentation medium: corn steep liquor 0.5%, soluble starch 0.3%, NH 4 SO 40.3%, KH 2 PO 4 0.15%, MgSO 4 0.05%, powdered chitin 1%, prepared with aged sea water, pH 8.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com