Multicomponent alloy coating for hot rolling roll and preparation method and coating method of multicomponent alloy coating

A multi-component alloy, hot roll technology, applied in metal material coating process, coating, melt spraying and other directions, can solve the thermal shock resistance of surface wear roll coating material, hot roll prone to thermal cracking, surface peeling, etc. problems, to achieve good high temperature oxidation resistance, reduce thermal stress, excellent heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

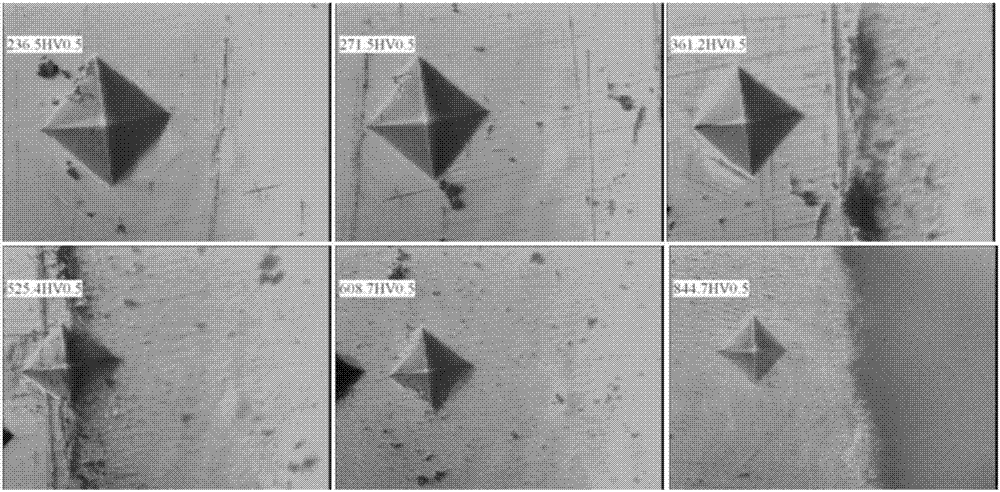

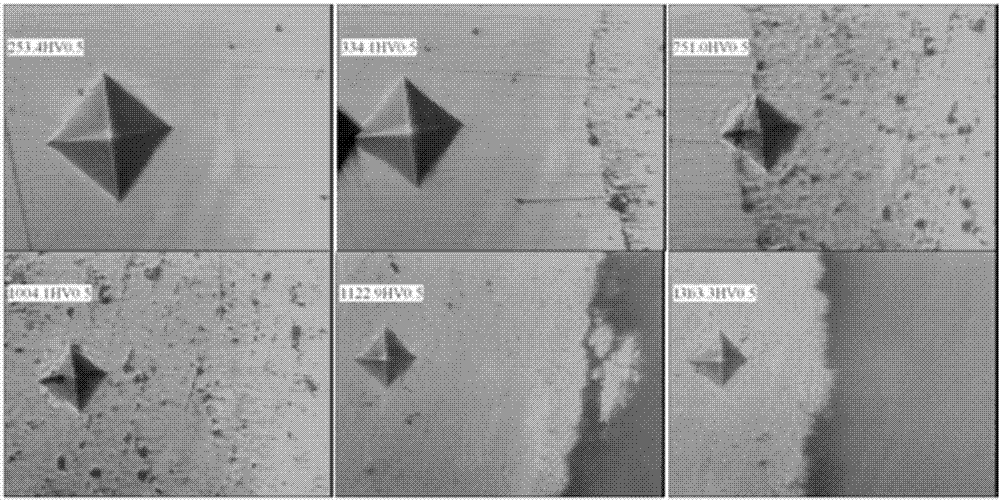

[0054] The hot roll multi-element alloy coating of the present embodiment, as figure 1 As shown, from the inside to the outside are the hot roll base layer, the transition layer and the working layer, the transition layer is NiCr sprayed layer; the working layer is NiCr-Cr 3 C 2 Composite coating.

[0055] The hot roll multi-element alloy coating material preparation of the present embodiment: NiCr nanopowder, NiCr-Cr 3 C 2 mixed nanopowder;

[0056] A kind of spraying method of the multi-component alloy coating of the present embodiment, the steps are:

[0057] Step 1) pre-treatment: mechanically grinding the surface of the hot roll, followed by sandblasting;

[0058] Step 2) Spraying: Spraying is performed by the HVOF method.

[0059] In the multi-element alloy coating of the hot roll and its preparation and spraying method in this embodiment, NiCr is sprayed on the base layer of the hot roll as a metal bonding layer, that is, a transition layer, which can eliminate th...

Embodiment 2

[0061] The basic structure of the multi-element alloy coating for hot rolling rolls in this embodiment is the same as that in Embodiment 1, except that the transition layer is a NiCrAl sprayed layer. Ni can react with Al to form intermetallic compounds and release a large amount of heat, so that the bonded bottom layer and the hot roll base layer form a micro-metallurgical bond, thereby improving the bonding strength of the bonded bottom layer and the hot roll base layer.

Embodiment 3

[0063] The basic structure of the multi-element alloy coating for hot rolling rolls of this embodiment is the same as that of Embodiment 1, the differences and improvements are: the thickness of the NiCr sprayed layer is 50 μm, the Cr content is 10%, and the Ni content is 90%; NiCr-Cr 3 C 2 Composite coating thickness is 200μm, Cr 3 C 2 The content is 70%, and NiCr is 30%. The NiCr bonding layer in this percentage range is compatible with NiCr-Cr 3 C 2 Cermets have good mutual melting properties.

[0064] The hot roll multi-element alloy coating material preparation of the present embodiment: NiCr nanopowder, NiCr-Cr 3 C 2 Mixed nano powder, wherein, nano Cr 3 C 2 The preparation method of powder is:

[0065] Step 1: Mixing: put ammonium dichromate powder and nano-carbon black powder in distilled water with a weight ratio of 1:0.17, mix and stir evenly to form a fluid state, and add it to a square mold Compression molding is a precursor; after compression, it is a blo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com