Method for preparing large-area non-cracking colloidal photonic crystal membrane

A colloidal photonic crystal, large-area technology is applied in the field of enhancing the fluorescence intensity of quantum dots, which can solve the problems of complex film-forming steps of photonic crystals, difficult to construct in a large area, easy to crack, etc. good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add polyurethane emulsion to the monodisperse polystyrene microsphere emulsion with a particle size of 228nm and a monodispersity coefficient of 1% to make a mixed solution, wherein the mass fraction of polystyrene microspheres is 30%, polyurethane The mass fraction is 1%. Sonicate to disperse evenly until there are no air bubbles. Then use a silk rod to scrape the surface of the PET plastic film with a contact angle of 18°, and wait for the solvent to dry to obtain a non-cracking photonic crystal film.

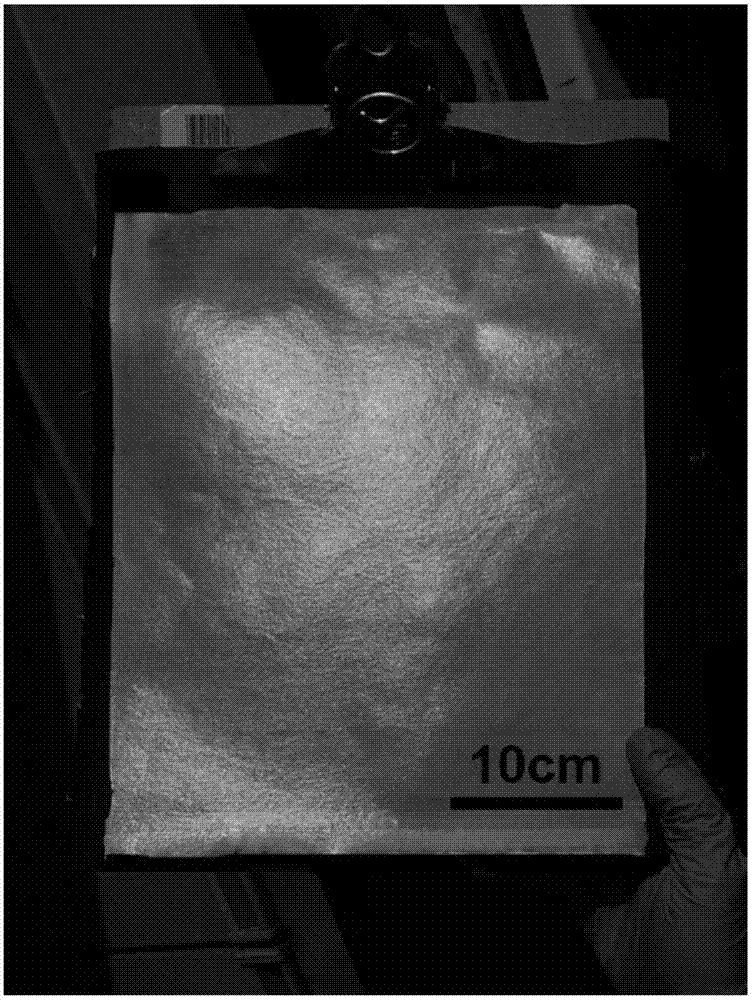

[0026] figure 1 It is the physical picture of the photonic crystal film, the size is 30*40cm, the photonic crystal film shows a bright green structural color, and the surface is uniform without cracking.

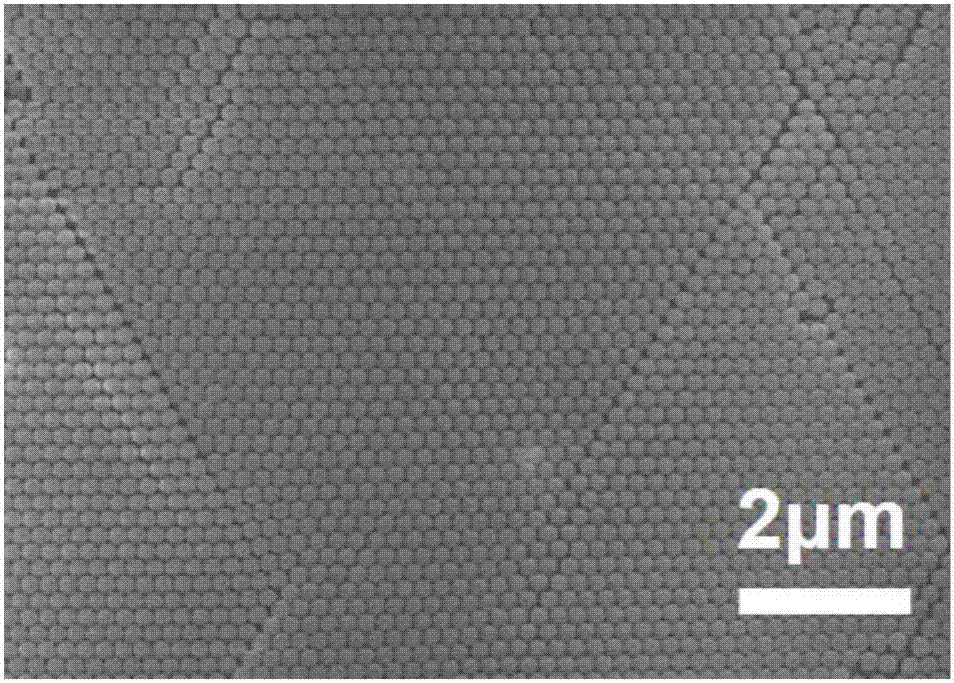

[0027] The photonic crystal film is scanned by electron microscope, the results can be found in figure 2 , the results show that the prepared photonic crystal film is composed of monodisperse colloidal particles, which are closely arranged in short-range order. ...

Embodiment 2

[0034] The particle size is 211nm, and the monodispersity coefficient is 3% surface carboxyl modified monodisperse polystyrene microspheres, add polyurethane emulsion, in the mixed solution that makes, polystyrene microsphere mass fraction is 35%, polyurethane mass fraction The score is 3%. Sonicate to disperse evenly until there are no air bubbles. Then scrape-coat the glass surface with a contact angle of 13° with a silk rod, and wait for the solvent to dry to obtain a non-cracking photonic crystal film.

[0035] Aqueous phase CdTe (emission peak 500nm) was added to 1% PVA aqueous solution to prepare a mixed solution. In the mixed solution, the mass fraction of CdTe was 0.5%, and the mass fraction of PVA was 1%. CdTe / PVA solution was added dropwise on the colloidal photonic crystal film, and spin-coated at a speed of 1500rpm for 45s.

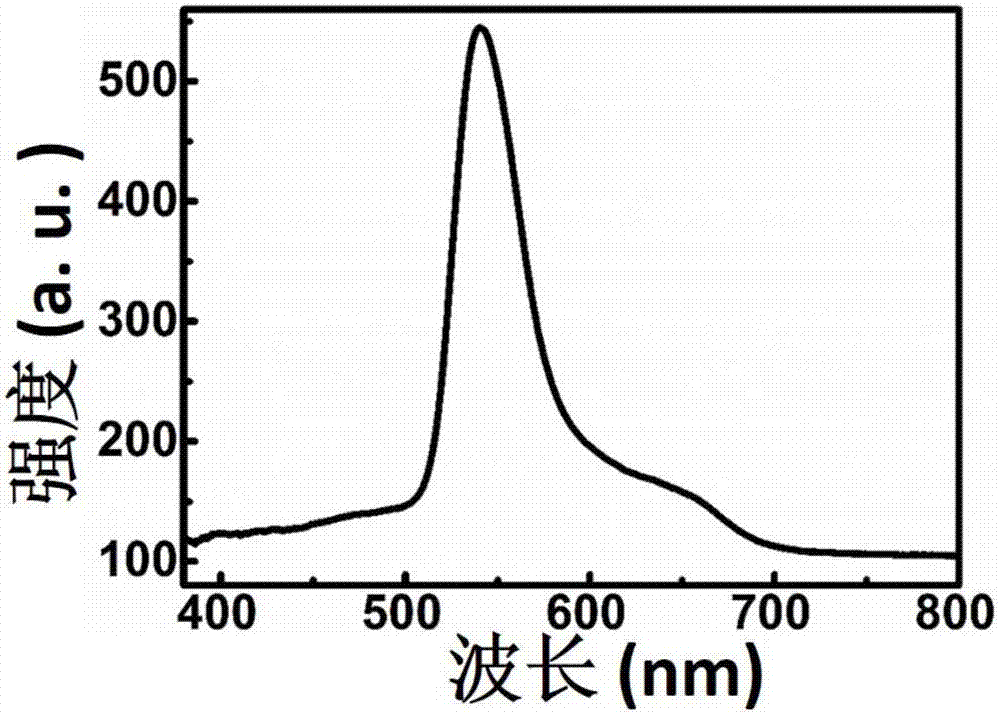

[0036] The size of the obtained photonic crystal film is 35*42cm. The reflection spectrum test of the obtained colloidal photonic crystal f...

Embodiment 3

[0038] Add polyurethane emulsion to the monodisperse polystyrene microspheres with a particle size of 256nm and a monodispersity coefficient of 5%, and in the mixed solution made, the mass fraction of polystyrene microspheres is 25%, and the mass fraction of polyurethane is 25%. The score is 5%. Sonicate to disperse evenly until there are no air bubbles. Then scrape coating on the surface of the silicon wafer with a contact angle of 24° with a wire rod, and the photonic crystal film without cracking can be obtained after the solvent is dried.

[0039] Aqueous phase CdTe (emission peak 610nm) was added to 1.5% PVA aqueous solution to prepare a mixed solution. In the mixed solution, the mass fraction of CdTe is 1%, and the mass fraction of PVA is 1.5%. CdTe / PVA solution was added dropwise on the colloidal photonic crystal film at the forbidden band position 610nm, and spin-coated at a speed of 2000rpm for 60s.

[0040] The size of the obtained photonic crystal film is 32*41cm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com