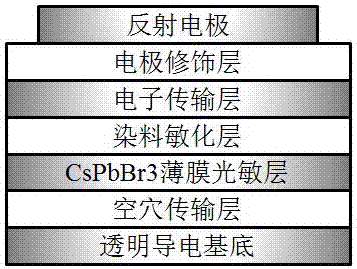

Phthalocyanine dye-sensitized CsPbBr3 photovoltaic cell and manufacturing method thereof

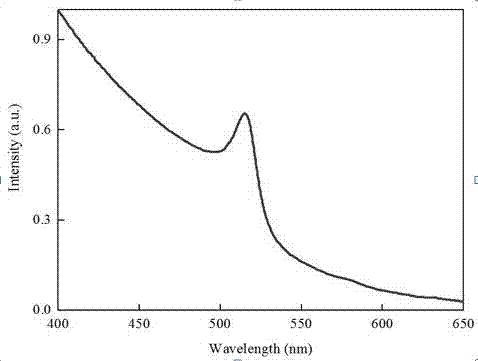

A photovoltaic cell and phthalocyanine dye technology, which is applied in the field of phthalocyanine dye-sensitized CsPbBr3 photovoltaic cells and its manufacturing field, can solve the limitation of CsPbBr3 cell photocurrent and cell energy conversion efficiency, cell short-circuit current, fill factor and open-circuit voltage characteristics Reduce parameters, increase the probability of electron-hole recombination, etc., to achieve the effect of increasing the photoresponse range, good protection, and improving energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

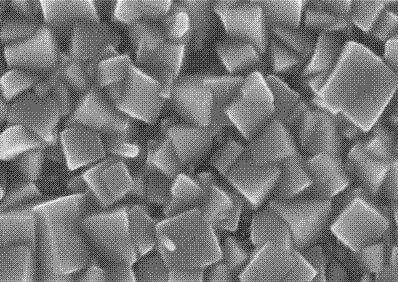

[0065] A phthalocyanine dye-sensitized CsPbBr3 photovoltaic cell and a manufacturing method thereof, the device structure is Glass / ITO / PEDOT:PSS / CsPbBr3 / SubPc / C60 / Bphen / Al from bottom to top.

[0066] An ITO glass substrate is provided, the ITO thickness is preferably 100-300 nm, the light transmittance is greater than 85%, and the sheet resistance is less than 10 Ω, and the CsPbBr3 photovoltaic cell is made according to the following steps:

[0067] (1) Cleaning of the transparent conductive substrate: The transparent conductive substrate is ultrasonically cleaned with acetone, isopropanol, and deionized water for 20 minutes in sequence, dried with nitrogen and irradiated with a UV lamp for 20 minutes;

[0068] (2) Form a hole transport layer on a transparent conductive substrate: take PEDOT:PSS as a hole transport layer, and deposit it on an ITO transparent conductive substrate by spin coating at a speed of 4000 rpm for 40 s, and then at 120°C Annealing on a heating plate fo...

Embodiment 2

[0086] A phthalocyanine dye-sensitized CsPbBr3 photovoltaic cell and a manufacturing method thereof, the device structure is Glass / ITO / PEDOT:PSS / CsPbBr3 / ClAlPc / PCBM / BCP / Ag from bottom to top.

[0087] Provide any of the above-mentioned ITO glass substrates, the ITO thickness is preferably 100-300 nm, the light transmittance is greater than 85%, and the sheet resistance is less than 10 Ω, and the CsPbBr3 photovoltaic cell is produced according to the following steps:

[0088] (1) Cleaning of transparent conductive substrate: same as embodiment one;

[0089] (2) Forming a hole transport layer on a transparent conductive substrate: same as embodiment one;

[0090] (3) Form a CsPbBr3 thin film photosensitive layer on the hole transport layer, and prepare the CsPbBr3 thin film photosensitive layer according to the following steps:

[0091]A, synthetic CsPbBr polycrystal: with embodiment one;

[0092] B, configuration CsPbBr Precursor solution: with embodiment one;

[0093] C. Sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface root mean square roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com