A composite nanofiltration membrane containing modified carbon nanotubes and its preparation method

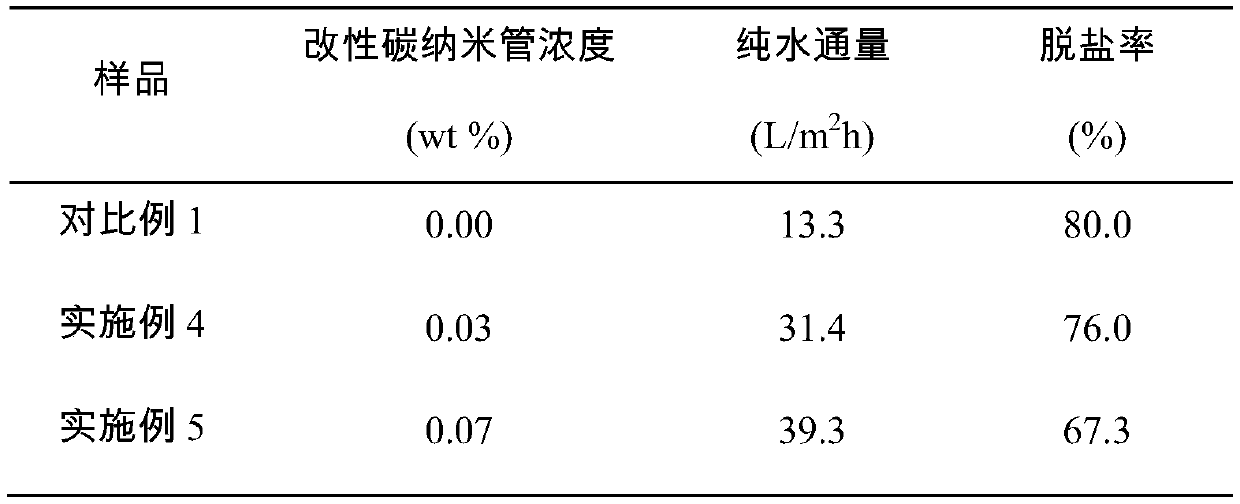

A composite nanofiltration membrane and carbon nanotube technology, applied in the fields of carbon compounds, chemical instruments and methods, membrane technology, etc., can solve the problems of long reaction time, low pure water flux of ultrafiltration membrane, etc., and achieve a simple modification method. , good industrial production basis, the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The embodiment of the present invention provides the above-mentioned preparation method of modified carbon nanotubes, comprising the following steps:

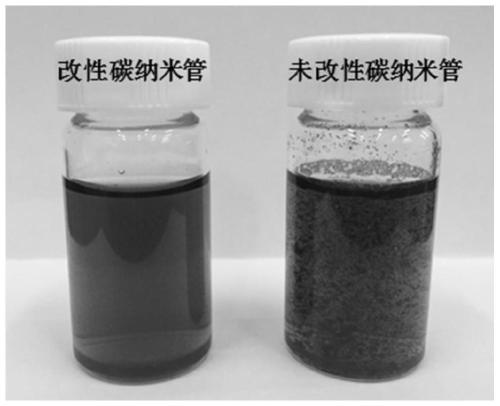

[0029] Disperse carbon nanotubes in water, add tannic acid solution, add iron salt solution after dispersion, and react under stirring to obtain modified carbon nanotubes.

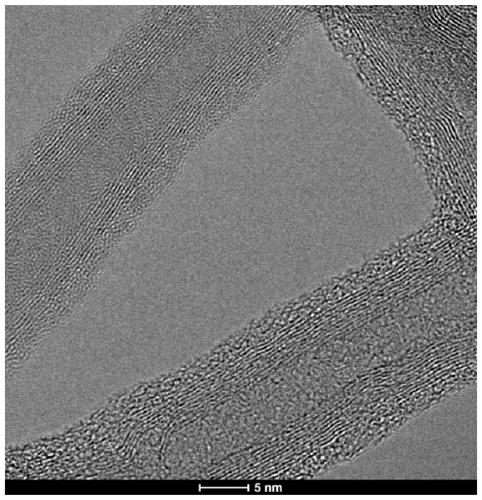

[0030] Specifically, ultrasonically disperse carbon nanotubes in water, add tannic acid solution for ultrasonication for a period of time, then add iron salt solution, react for a period of time under stirring, centrifuge, wash with deionized water, and freeze-dry to obtain modified carbon nanotubes. Further, in a preferred embodiment of the present invention, the carbon nanotubes are selected from one or more of single-walled carbon nanotubes, multi-walled carbon nanotubes, native carbon nanotubes, and modified carbon nanotubes. It can be understood that the modified carbon nanotubes may be carboxylated carbon nanotubes, hydroxylated carbon nanotube...

Embodiment 1

[0053] A kind of modified carbon nanotube provided by the present embodiment is prepared according to the following steps:

[0054] First, the content of 0.1wt% carbon nanotubes (multi-walled, OD3+ The molar ratio to tannic acid is 5 / 2), reacted for 1 min under stirring, centrifuged and washed with deionized water, and freeze-dried to obtain modified carbon nanotubes.

Embodiment 2

[0056] A kind of modified carbon nanotube provided by the present embodiment is prepared according to the following steps:

[0057] Firstly, carbon nanotubes with a content of 0.2wt% are ultrasonically dispersed in an aqueous solution, tannic acid solution (the weight ratio of tannic acid and carbon nanotubes is 5 / 1) is ultrasonically dispersed for 0.5h, and ferric chloride solution (Fe 3+ The molar ratio with tannic acid is 2 / 1), reacted with stirring for 0.5min, centrifuged and washed with deionized water, and freeze-dried to obtain modified carbon nanotubes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com