Method for silver nanowire purification through vibration and sedimentation

A technology of silver nanowires and purification methods, which is applied in nanotechnology, transportation and packaging, metal processing equipment, etc., can solve the problems of prolonging the processing cycle, consuming a large amount of acetone, and large consumption of reagents, so as to shorten the purification time and reduce consumption Quantity, good effect of purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

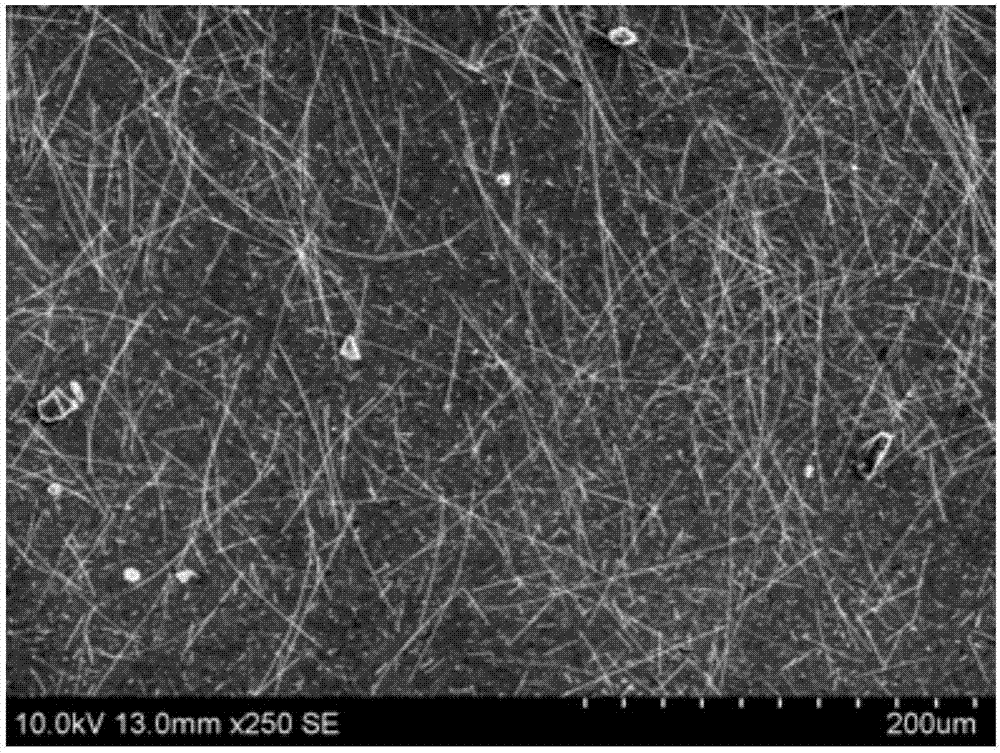

[0024] Embodiment 1: prepare silver nanowire according to polyol method, operation is as follows: first prepare solution, comprise A(CuCl 2 Soluble in ethylene glycol (EG), Cl - Concentration is 1mM), B (190mg PVP dissolved in 15mL EG, where PVP molecular weight is 1,300,000), C (240mgAgNO 3 dissolved in 15 mL EG). Add 3.17mL of solution A into 46.8mL of EG, preheat to 170°C, add 15mL of solution B, heat to 170°C, add 15mL of solution C to the above solution evenly within 60 minutes, and keep warm at 170°C for 20 minutes. Cool in air to obtain silver nanowire mother liquor. The solid content in the mother liquor is about 1.9mg / mL. figure 1 It is a scanning electron micrograph of unpurified nanowires, and the length of the nanowires is between 0-220 μm. In addition to nanowires, the product also contains more nanoparticles. Follow the steps below to purify:

[0025] Step 1. Take 3mL of mother liquor, add 9mL of acetone to it, use a mixer to vibrate at a rate of 2000 rpm f...

Embodiment 2

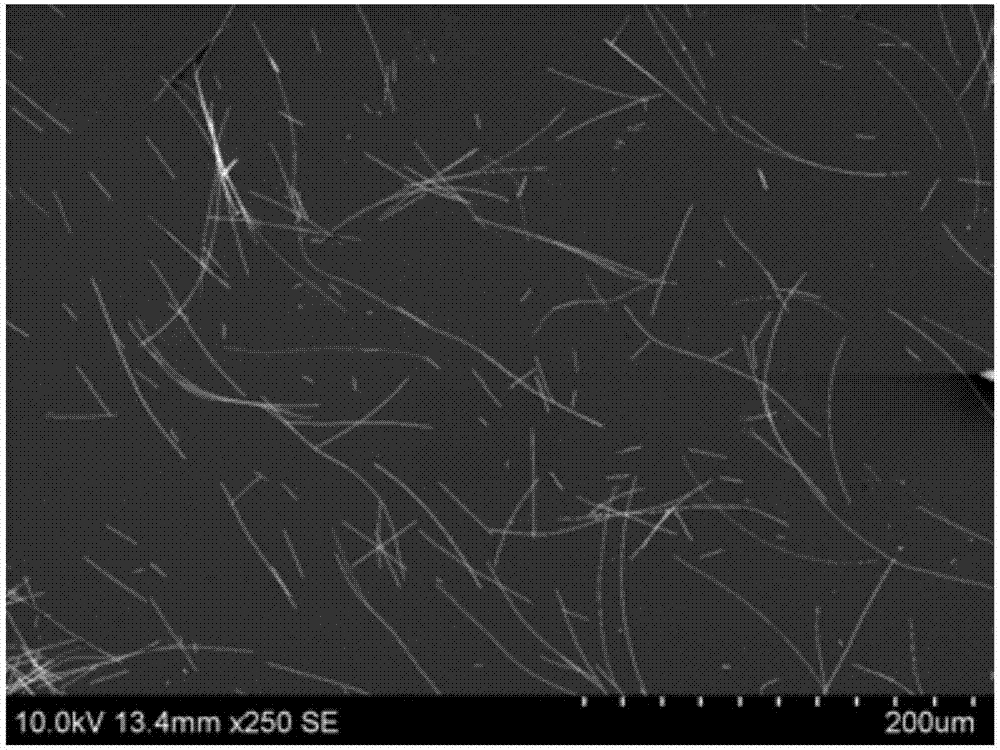

[0029] Embodiment 2: prepare silver nanowire according to polyol method, operation is as follows: first preparation solution, solvent is EG, comprises A (KBr solution, concentration is 2mM), B (PVP solution, concentration is 300mM, wherein PVP molecular weight is 1,300,000 ), C (AgNO 3 solution, the concentration is 300mM). Add 12.008mL of EG, 2.116mL of solution A, 3.526mL of solution B, and 2.351mL of solution C into the flask in turn, stir for 30min, put it in a preheated oil bath and heat to 150°C, keep it warm for 3h without stirring, and in air cooling in medium to obtain silver nanowire mother liquor. The solid content in the mother liquor is about 3.8mg / mL. image 3 It is a scanning electron micrograph of unpurified nanowires, and the length of the nanowires is between 0-80 μm. In addition to nanowires, the product also contains more stubby nanorods, submicron and micron particles. Purify as follows:

[0030] Step 1. Take 6mL of mother liquor, add 18mL of acetone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com