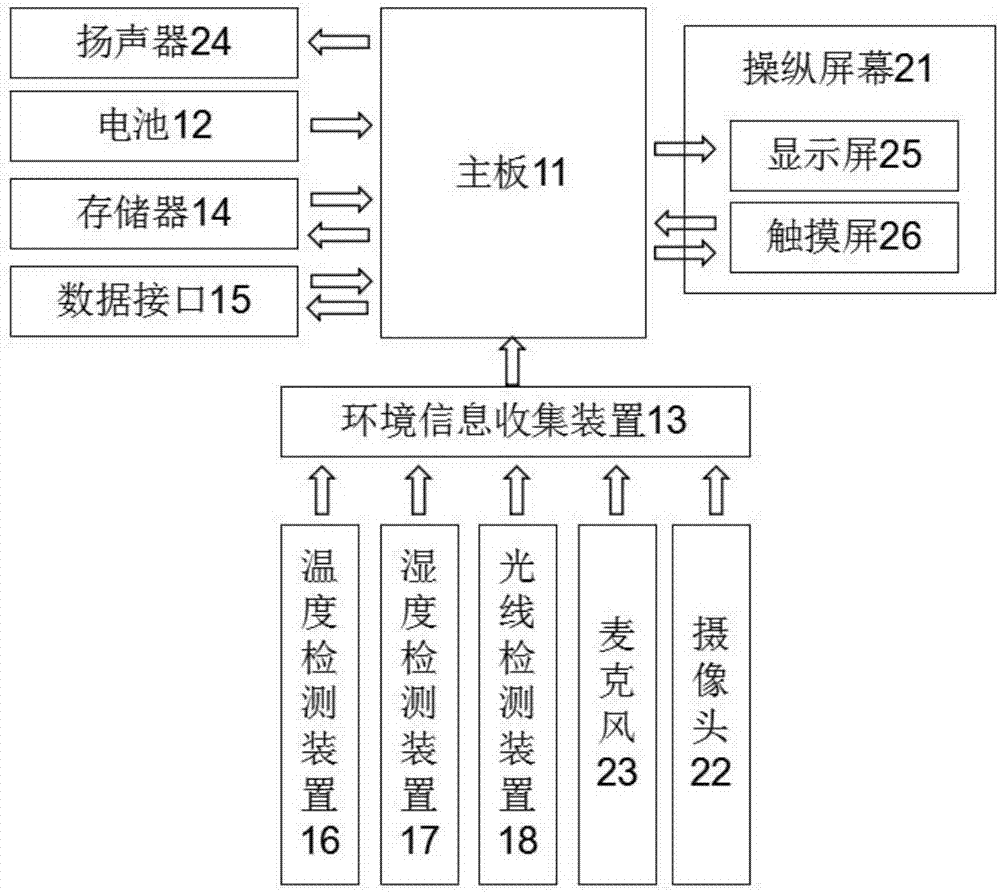

Touch type elevator control box and elevator control system

A manipulation box, touch-type technology, applied in circuits, electrical components, transistors, etc., can solve the problems of increasing the footprint of the manipulation box, affecting the appearance, and troublesome control of high-rise buildings, so as to improve functionality and convenience, and avoid safety. Hidden dangers and the effect of preventing major fires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The preparation steps of the thin film field effect transistor 37 include:

[0055] Step 1: Deposit tungsten-doped indium oxide thin film on the glass substrate, using DC reactive magnetron sputtering coating process, sputtering current 120mA, sputtering voltage 300-320V, sputtering at room temperature for 15min, to obtain the thickness of tungsten-doped indium oxide thin film 100nm;

[0056] Step 2: Prepare Al source-drain electrodes, using thermal evaporation process, when the vacuum degree is lower than 3×10-3Pa, turn on the evaporation power supply, heat the tungsten boat to evaporate Al, the evaporation current is 120mA, and the time is 1.5min to ensure that the prepared Al The electrode sheet resistance is less than 5Ω, the thickness is 100nm, and the resistivity is lower than 3×10-5Ω·cm;

[0057] Step 3: Prepare the PVP gate dielectric layer, dissolve polytetravinylphenol powder in absolute ethanol solution, stir until completely dissolved to obtain a solution w...

Embodiment approach

[0059] As a preferred embodiment, the first step includes the following steps:

[0060] Step 1.1: Immerse the glass substrate in an acetone ultrasonic bath for 10 minutes, then place it in fast-flowing warm water for 5 minutes, and finally wash it with deionized water for 5-10 minutes until a uniform water film is formed on the surface of the glass substrate;

[0061] Step 1.2: immerse the glass substrate in absolute ethanol and ultrasonically clean it for 15 minutes;

[0062]Step 1.3: Take out the glass substrate and place it in deionized water for ultrasonic cleaning for 10 minutes, then take out the glass substrate and dry it in a constant temperature oven at 120°C;

[0063] Step 1.4: Introduce argon and nitrogen, the total working pressure is 0.35Pa, keep the flow ratio of argon and nitrogen at 2:1, and use DC reactive magnetron sputtering to obtain the tungsten-doped indium oxide film with a thickness of 100nm .

[0064] This embodiment also provides an elevator control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com