Method for preparing and comprehensively utilizing metal aluminum through coal ash pellet chlorination electrolysis

A technology for fly ash and metal aluminum, applied in chemical instruments and methods, silicon compounds, non-metallic elements, etc., can solve the problems of inability to comprehensively utilize, long process, and high energy consumption, so as to improve resource utilization and reduce emissions. , the effect of high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

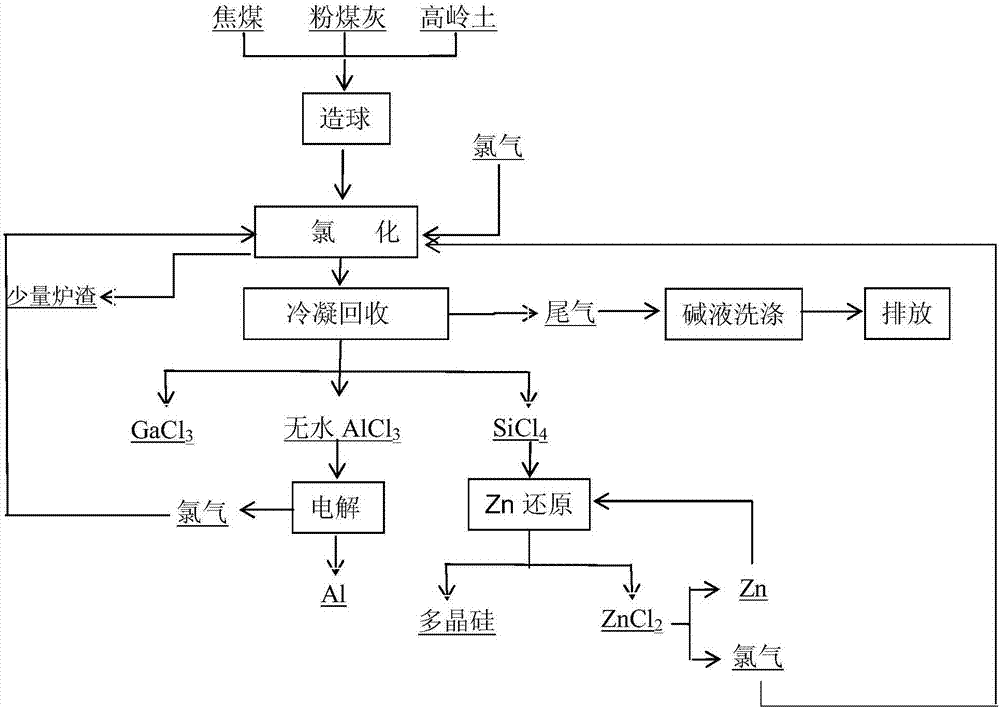

[0053] A method for preparing metal aluminum by chlorination and electrolysis of fly ash pellets and its comprehensive utilization, the process flow chart is as follows figure 1 As shown, it specifically includes the following steps:

[0054] (1) Ingredients:

[0055] Get alumina content and be 25%, the high-alumina fly ash that silicon oxide content is 54%, according to mass ratio, high-alumina fly ash: coking coal: kaolin=1: 0.2: 0.01 batching, mix uniformly, form mixed material, to Add the water glass of 1.0% of the total mass of the mixed material and the water of 2.0% of the total mass of the mixed material in the mixed material;

[0056] (2) Ball making:

[0057] Mix the mixed material, water glass and water evenly, make pellets to obtain pellets with a particle size of 5mm, and air-dry the pellets naturally for 10 hours;

[0058] (3) Pellet chlorination and separation:

[0059] After the pellets are heated and chlorinated by microwaves, a mixture of anhydrous alumin...

Embodiment 2

[0067] A method for preparing metal aluminum by chlorination and electrolysis of fly ash pellets and its comprehensive utilization, the process flow chart is as follows figure 1 As shown, it specifically includes the following steps:

[0068] (1) Ingredients:

[0069] Get alumina content and be 38%, the high-alumina fly ash that silicon oxide content is 41%, according to mass ratio, high-alumina fly ash: coking coal: kaolin=1: 0.2: 0.03 batching, mix uniformly, form mixed material, to Add the water glass of 1.8% of the total mass of the mixed material and the water of 4.6% of the total mass of the mixed material in the mixed material;

[0070] (2) Ball making:

[0071] Mix the mixed material, water glass and water evenly, make pellets to obtain pellets with a particle size of 16mm, and dry the pellets naturally for 22 hours;

[0072] (3) Pellet chlorination and separation:

[0073] After the pellets are heated and chlorinated by microwaves, a mixture of anhydrous aluminum ...

Embodiment 3

[0081] A method for preparing metal aluminum by chlorination and electrolysis of fly ash pellets and its comprehensive utilization, the process flow chart is as follows figure 1 As shown, it specifically includes the following steps:

[0082] (1) Ingredients:

[0083] Get alumina content and be 33%, the high-alumina fly ash that silicon oxide content is 47%, according to mass ratio, high-alumina fly ash: coking coal: kaolin=1: 0.4: 0.02 batching, mix uniformly, form mixed material, to Add the water glass of 1.4% of the total mass of the mixed material and the water of 2.6% of the total mass of the mixed material in the mixed material;

[0084] (2) Ball making:

[0085] Mix the mixed material, water glass and water evenly, pelletize to obtain pellets with a particle size of 10mm, and air-dry the pellets naturally for 14 hours;

[0086] (3) Pellet chlorination and separation:

[0087] After the pellets are heated and chlorinated by microwaves, a mixture of anhydrous aluminum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com