In-vitro intervention embolism therapy simulation system

A technology of simulation system and treatment system, applied in teaching models, instruments, educational appliances, etc., can solve the problem of inability to evaluate the performance of embolic agents, achieve convenient data accumulation scheme, and inhibit the effect of neovascularization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

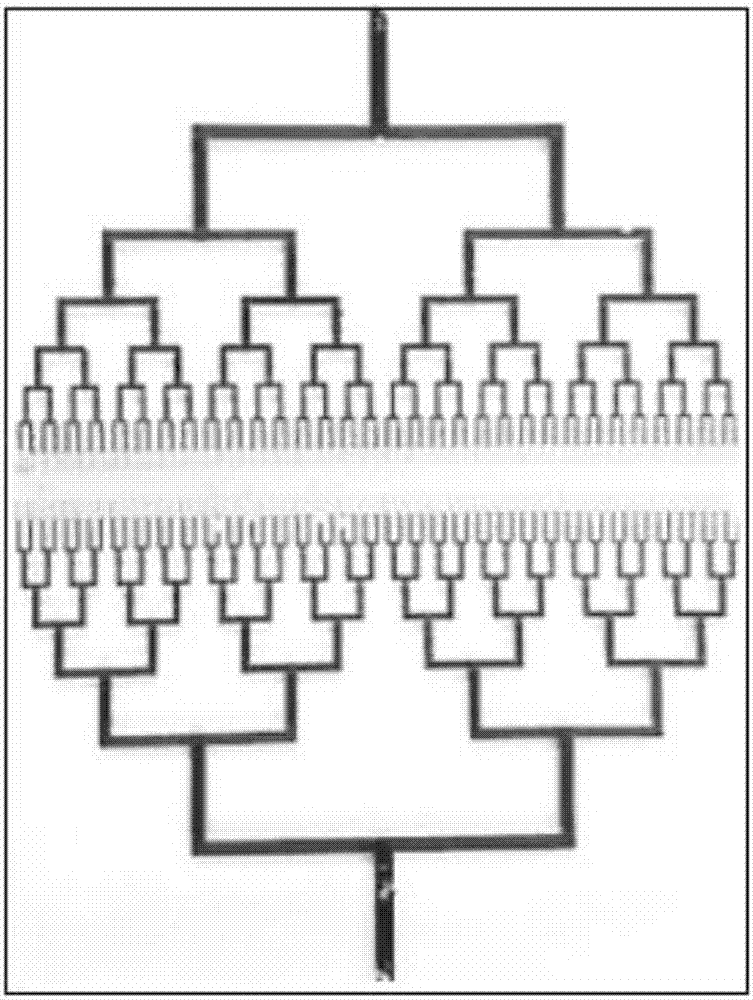

[0047] Wherein, the preparation method of the microfluidic chip 3 includes the following steps,

[0048] 1) Mix polydimethylsiloxane and curing agent according to the mass ratio of 10:1, put it in a beaker, stir and mix evenly with a glass rod, and pour the mixture on a mold with a chip in place, at 60°C Curing for 2 hours;

[0049] 2) Use a blade to cut off the cured substrate, and use a puncher to make holes at the punching positions;

[0050] 3) Bond the cured upper and lower substrates, and store them in an oven at 50° C. for 30 minutes to complete the bonding.

[0051] The curing agent adopted in the present invention is Dow Corning Sylgard184.

[0052] In the present invention, the simulated blood flow medium 5 is phosphate buffer solution with pH=7.4 or 0.9% physiological saline.

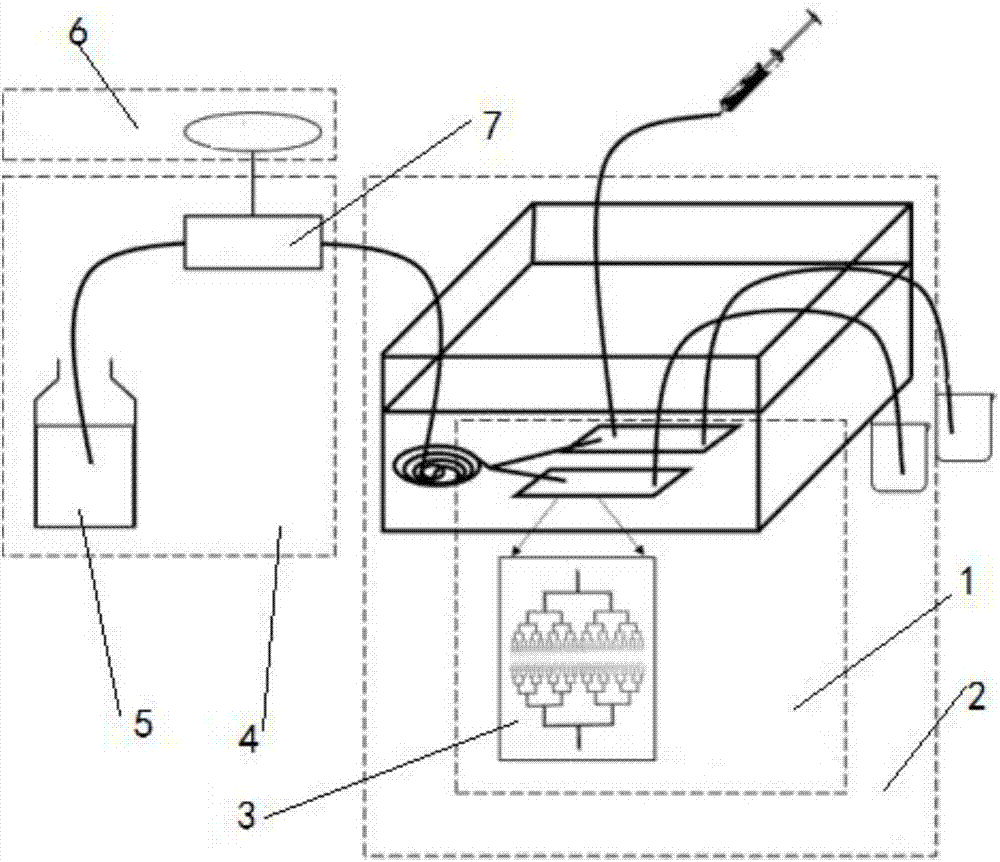

[0053] The simulation system for extracorporeal interventional embolization therapy in the present invention is realized in the following ways:

Embodiment 1

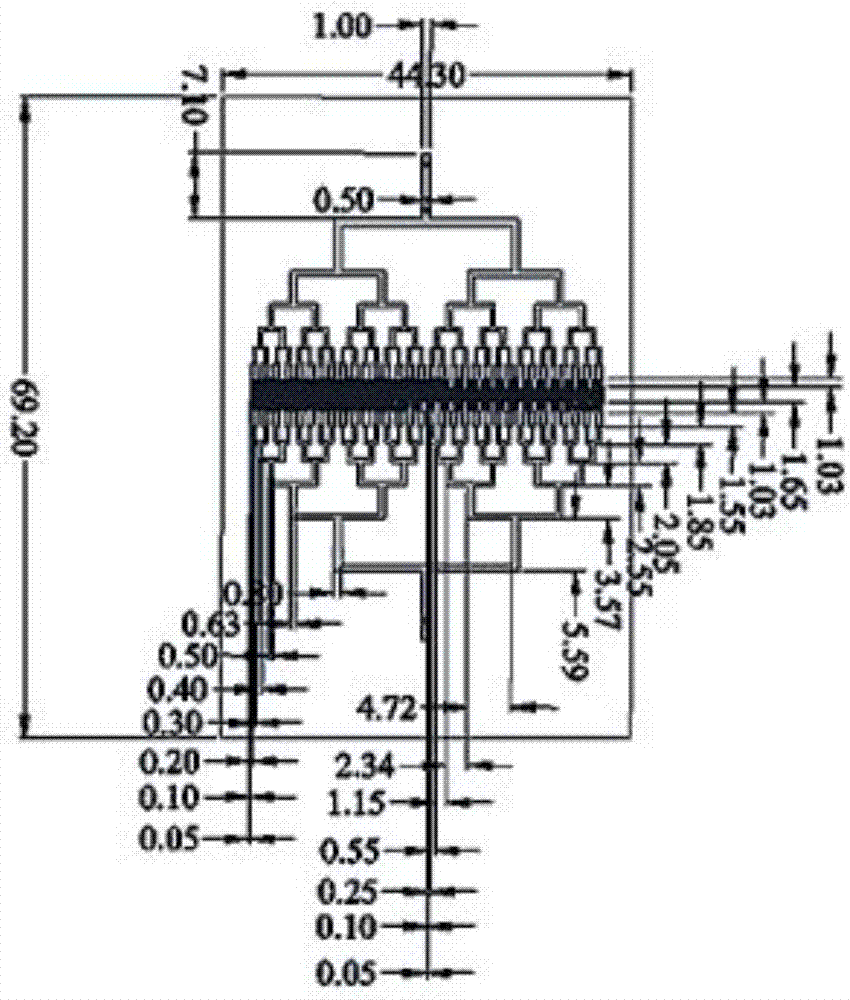

[0055] Step 1: Mix polydimethylsiloxane and curing agent according to the mass ratio of 10:1, put it in a beaker, stir with a glass rod for 30 minutes, stir well, and pour the mixture on the mold (pipeline design in the mold Classified into 9 grades, the pipe widths are 1000 μm, 800 μm, 630 μm, 500 μm, 400 μm, 300 μm, 200 μm, 100 μm, 50 μm, and the pipe height is 20-50 μm), cured at 60 ° C for 2 hours;

[0056] Step 2: Use a blade to cut off the cured substrate, and use a puncher to make a hole at the punching position;

[0057] Step 3: Bond the cured substrate to the glass, and store it in an oven at 50°C for 30 minutes to make the bonding complete, and obtain a microvascular simulation chip;

[0058] Step 4: Repeat the above steps to prepare 2 or more microvascular simulation chips;

[0059] Step Five: Follow the figure 1 After the construction of each component is completed, turn on the thermostat 2, set the system temperature to 37°C, turn on the constant flow pump 7 and...

Embodiment 2

[0061] Step 1: Mix polydimethylsiloxane and curing agent according to the mass ratio of 10:1, put it in a beaker, stir with a glass rod for 30 minutes, stir well, and pour the mixture on the mold (pipeline design in the mold Classified into 9 grades, the pipe widths are 1000 μm, 800 μm, 630 μm, 500 μm, 400 μm, 300 μm, 200 μm, 100 μm, 50 μm, and the pipe height is 50-100 μm), cured at 60 ° C for 2 hours;

[0062] Step 2: Use a blade to cut off the cured substrate, and use a puncher to make a hole at the punching position;

[0063] Step 3: Bond the cured substrate to the glass, and store it in an oven at 50°C for 30 minutes to make the bonding complete, and obtain a microvascular simulation chip;

[0064] Step 4: Repeat the above steps to prepare 2 or more microvascular simulation chips;

[0065] Step Five: Follow the figure 1 After the construction of each component is completed, turn on the thermostat 2, set the system temperature to 37°C, turn on the constant flow pump 7 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com