Membrane separation process of tobacco extracting solution

A tobacco extract liquid and membrane separation technology, applied in the field of membrane separation, can solve the problems of poor taste quality of tobacco, incomplete separation and impurity removal methods, etc., and achieve reduced concentration polarization, stable membrane flux, and high tangential flow velocity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the examples, but it is not any limitation of the content scope of the present invention.

[0036] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

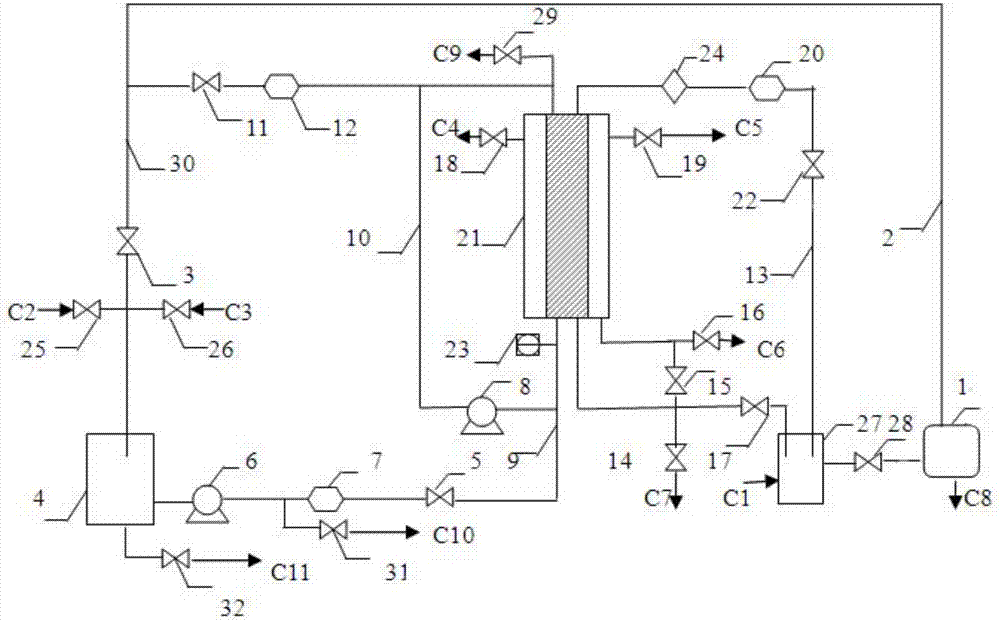

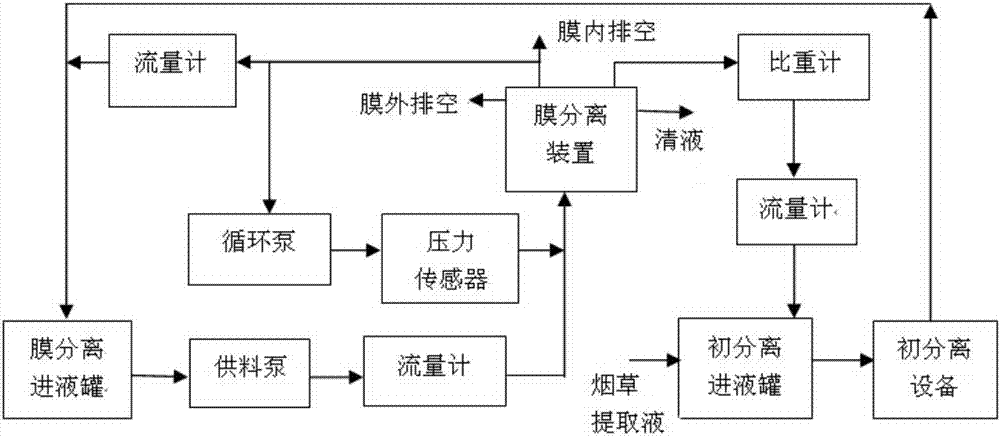

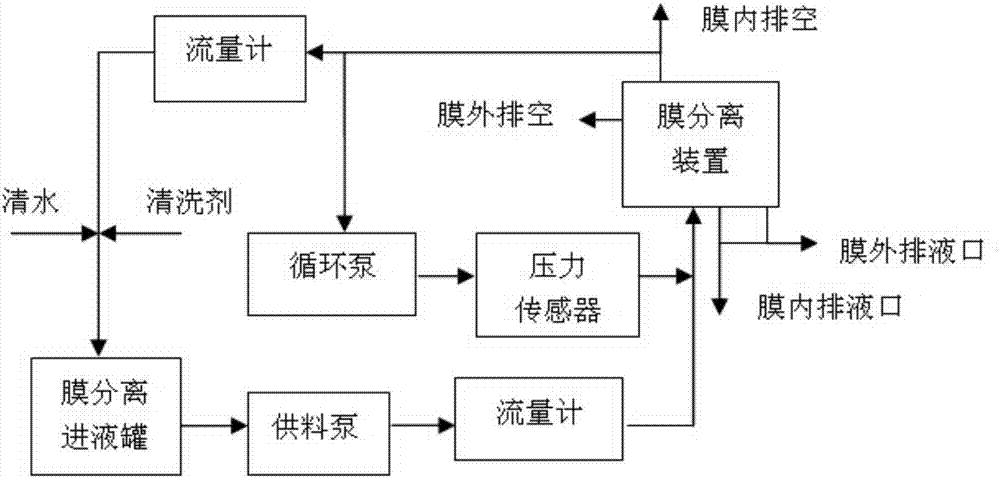

[0037] like figure 1 As shown, the membrane separation system consists of five parts: a pretreatment device, a membrane separation device, a reflux device, a cleaning device and an emptying device, among which:

[0038] Described pre-processing device comprises interconnected tobacco extraction liquid storage tank 27 and primary separation device 1, and primary separation device 1 connects membrane separation liquid inlet tank 4 through pipeline 2, and liquid valve 3 is set on pipeline 2; Membrane separation The liquid inlet tank 4 is connected to the membrane separation dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com