Oil sludge modifier and method for performing modified treatment on oil sludge to transform into novel regenerated solid fuel thereof

A solid fuel and modifier technology, applied in solid fuel, sludge treatment, chemical instruments and methods, etc., can solve the problems of limited treatment capacity, high treatment cost, secondary pollution, etc., and achieve good combustion performance and preparation process. Simple, high burn rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

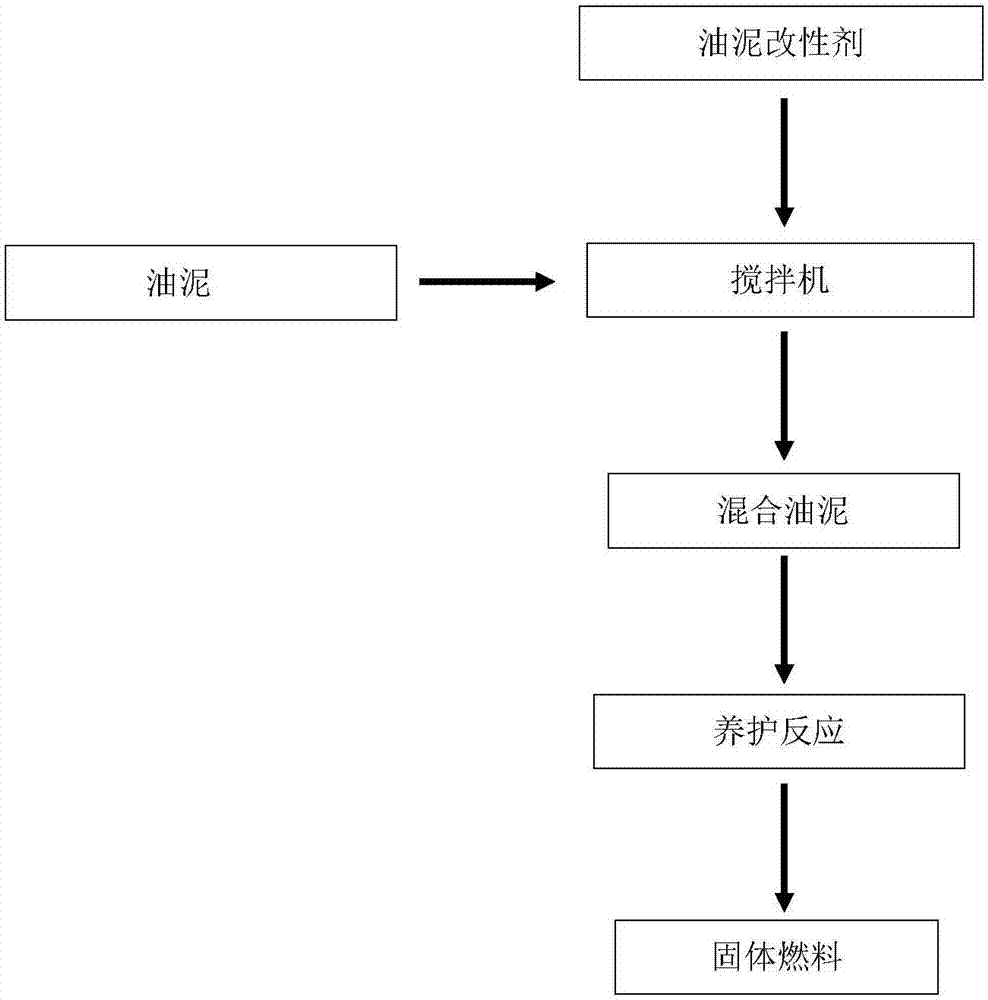

Method used

Image

Examples

Embodiment 1

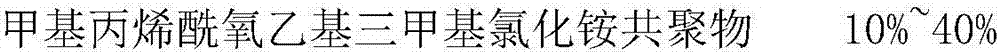

[0028] The oil sludge modifying agent of the present embodiment consists of methacryloyloxyethyl trimethyl ammonium chloride copolymer, dimethyl diallyl ammonium chloride and acrylamide copolymer, sodium carboxymethyl cellulose, pozzolan Mass percentage 10%:30%:30%:30% mixed evenly.

Embodiment 2

[0030] The oil sludge modifying agent of the present embodiment consists of methacryloyloxyethyl trimethyl ammonium chloride copolymer, dimethyl diallyl ammonium chloride and acrylamide copolymer, sodium carboxymethyl cellulose, pozzolan Mass percentage 30%: 20%: 25%: 25% mixed evenly.

Embodiment 3

[0032] The oil sludge modifying agent of the present embodiment consists of methacryloyloxyethyl trimethyl ammonium chloride copolymer, dimethyl diallyl ammonium chloride and acrylamide copolymer, sodium carboxymethyl cellulose, pozzolan Mass percentage 40%: 15%: 10%: 35% mixed evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com