ABS (Acrylonitrile Butadiene StyreneAcrylonitrile Butadiene Styrene) reinforced modified PBT (Polybutylece Terephthalate) composition

A composition and modification technology, which is applied in the field of polymer materials, can solve problems such as warping of parts and affecting appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

[0031] Prepared as follows:

[0032] The ABS resin was produced using a tandem polymerization apparatus in which 3 complete mixing type reactors were connected in series. The first stage consists of the first reactor and the second stage consists of the second reactor and the third reactor.

[0033] Use a plunger pump to contain 65.7 parts by weight of styrene, 21.4 parts by weight of acrylonitrile, 10.3 parts by weight of rubbery polymer, 0.12 parts by weight of tert-dodecyl mercaptan and 0.028 parts by weight of 1,1-bis(tert-butyl peroxy) - A first charge of 3,3,5-trimethylcyclohexane is continuously fed at a rate of 7.0 kg / hour into the first reactor where the monomer is polymerized. In this case, the polymerization temperature was adjusted so that the solid content at the outlet of the first reactor (i.e., the amount of the rubbery polymer and the styrene / acrylonitrile copolymer in the polymerization solution) was 22.1% by weight relative to the weight of the polymerizati...

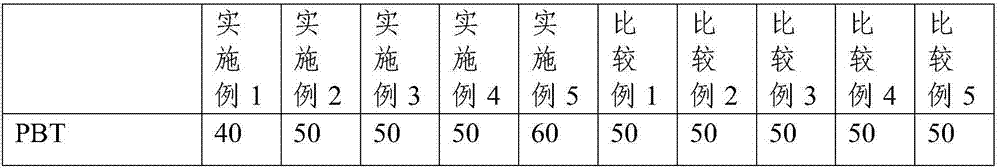

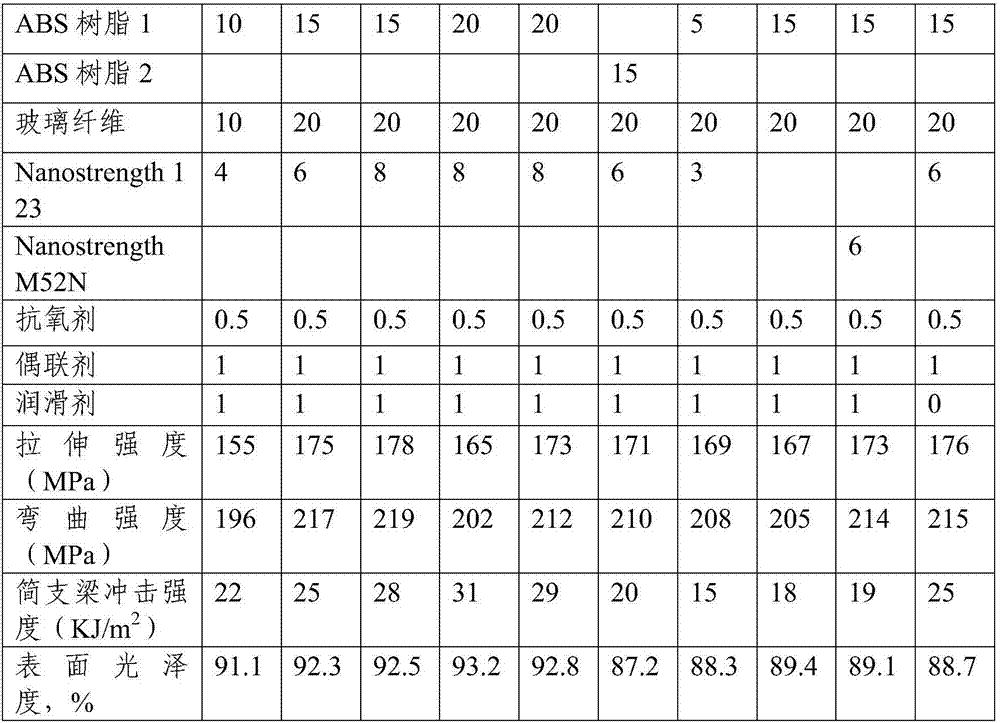

Embodiment

[0039] ABS reinforced modified PBT particles are prepared by the following methods:

[0040] a: Weigh PBT and ABS according to the weight ratio, mix them evenly, bake the PBT at 150°C for 2 hours before mixing, and control the moisture content to less than 0.05%;

[0041] b: Weigh the coupling agent and glass fiber according to the weight ratio, and mix them evenly;

[0042] c: Take the triblock copolymer, lubricant and antioxidant of poly(styrene) / poly(butadiene) / poly(methyl methacrylate) by weight ratio, mix them uniformly, and then mix them with Add the mixed materials in step a into the high-speed mixer and continue mixing until uniform. The speed of the high-speed mixer is 800 rpm, and the mixing time is 2-3 minutes;

[0043] d: Put the raw materials mixed in step c into the hopper of the twin-screw extruder, add the glass fiber modified by the silane coupling agent surface at the special glass fiber port of the twin-screw extruder, and melt and extrude it to produce Gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com