A method and device for extracting xylooligosaccharides from straw with steam explosion pretreatment

A xylooligosaccharide and pretreatment technology, which is applied in the direction of xylose production, sugar production, sugar production, etc., can solve the problems of staff hazards, noise pollution, straw intermingling, etc., to achieve easy separation and recycling, and to protect health , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

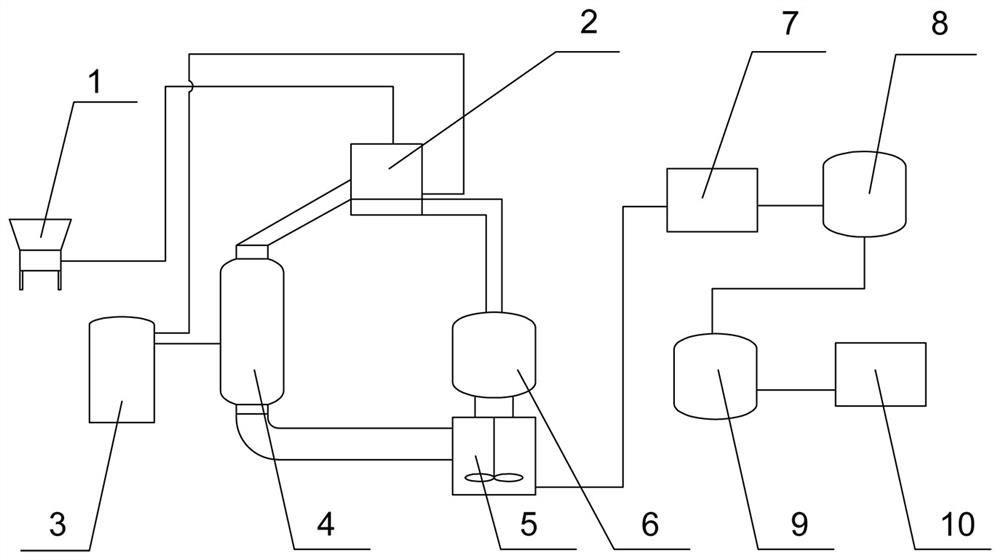

[0034] Such as figure 1 As shown, a method for extracting xylooligosaccharides from steam explosion pretreatment stalks comprises the following steps:

[0035] a. Material preparation: Take the straw and add it to the pulverizer 1 for mechanical crushing. The crushed straw does not exceed 3 cm. Pour the crushed straw into the preheating tank 2, and use the steam tank 3 to deliver steam to the warm up;

[0036] b. Steam explosion treatment: Add the straw preheated in step a directly into the steam explosion tank 4, seal it, and use the steam tank 3 to transport steam to the steam explosion tank 4 to a temperature of 208-223°C and a pressure of 1.3-1.5MPa, and maintain 90 ~105 seconds, rapid pressure release, steam returns to preheating tank 2 to preheat straw, and the material is released into the atmospheric pressure container 5 with water inside;

[0037] c. Filtration: the material in the step b atmospheric pressure vessel is filtered through the plate and frame filter pre...

Embodiment 2

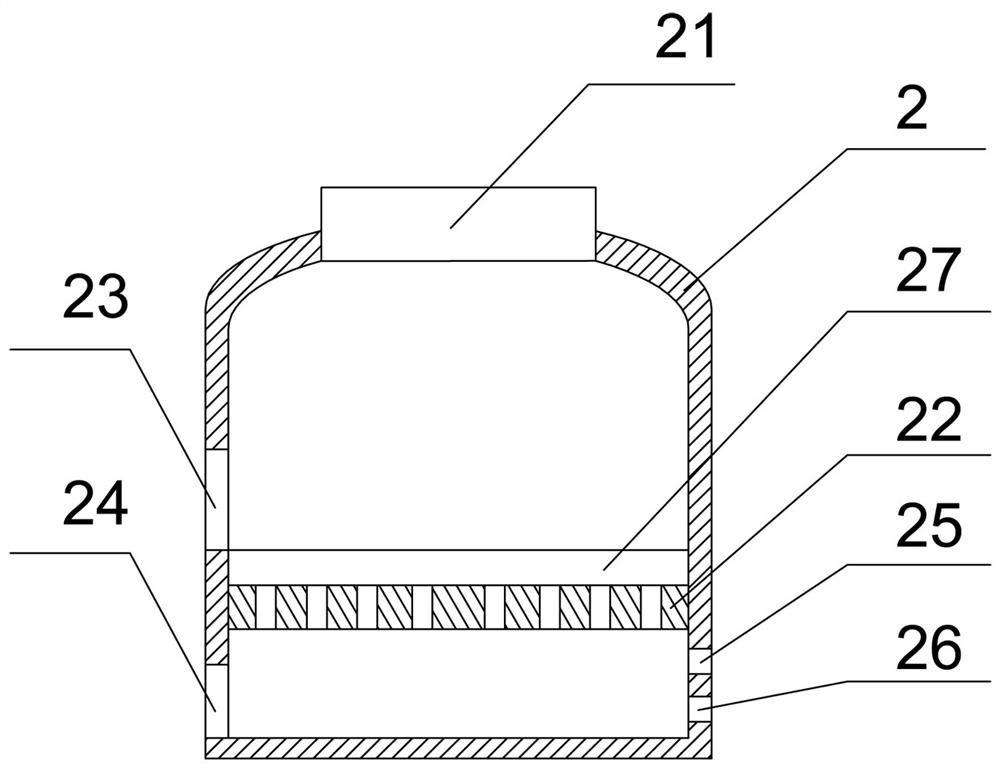

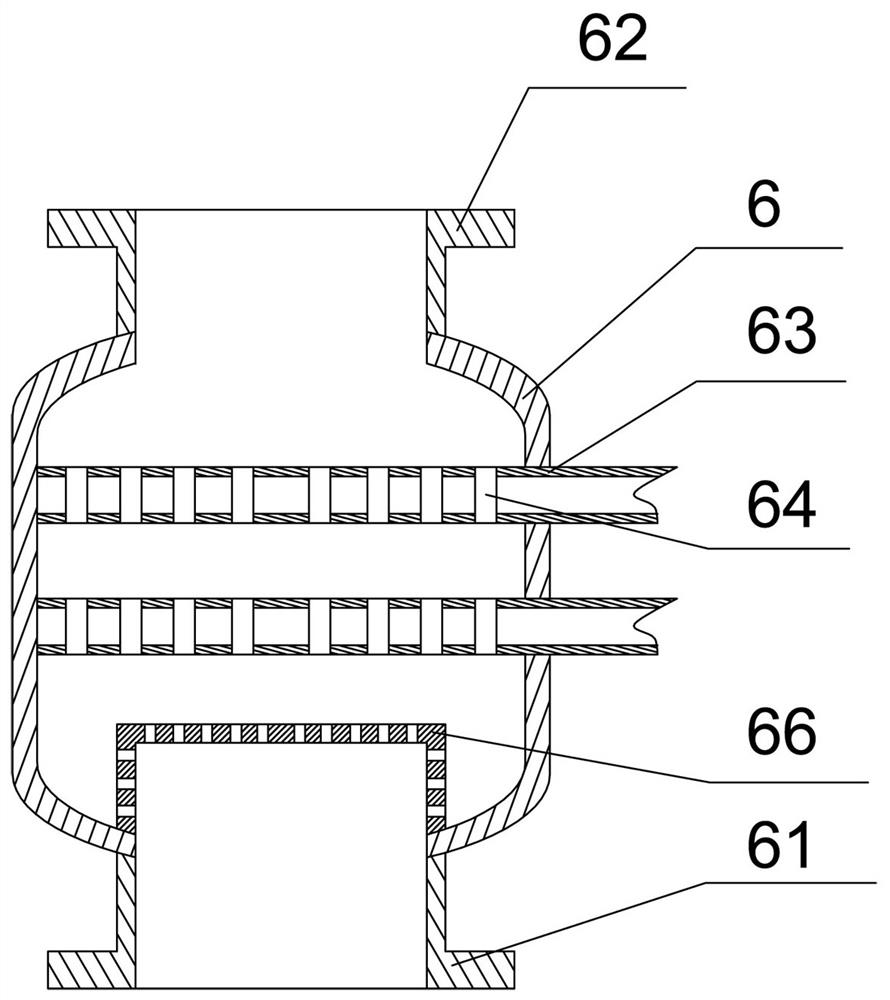

[0042] Such as Figure 2 to Figure 7 As shown, a device for extracting xylo-oligosaccharides from straw with steam explosion pretreatment includes a pulverizer 1, a steam tank 3, a steam explosion tank 4, an atmospheric pressure vessel 5, a plate and frame filter press 7, a decolorization tank 8, and a reaction kettle 9 and evaporation crystallizer 10, also includes noise reduction tank 6 and preheating tank 2, described pulverizer 1, is used for the mechanical pulverization of straw; Provide steam; the atmospheric pressure container 5 is used to accept and rapidly cool the material after the steam explosion; the plate and frame filter press 7 is used to remove the solid slag in the blasting material; the decolorization tank 8 is used to remove Impurities of the filtrate obtained in step c; the reaction kettle 9 is used for the degradation of the xylan solution to prepare the xylooligosaccharide solution; the evaporation crystallizer 10 is used for evaporating and concentratin...

Embodiment 3

[0044] Such as Figure 1 to Figure 7 As shown, a method for extracting xylo-oligosaccharides from steam-explosion pretreated straws and its device, a method for extracting xylo-oligosaccharides from steam-explosion pretreated straws includes the following steps:

[0045] a. Material preparation: Take the straw and add it to the pulverizer 1 for mechanical crushing. The crushed straw does not exceed 3 cm. Pour the crushed straw into the preheating tank 2, and use the steam tank 3 to deliver steam to the warm up;

[0046] b. Steam explosion treatment: Add the straw preheated in step a into the steam explosion tank 4, seal it, use the steam tank 3 to transport steam to the steam explosion tank 4 to a temperature of 208-223°C, a pressure of 1.3-1.5MPa, and maintain a temperature of 90- 105 seconds, rapid pressure relief, steam returns to the preheating tank 2 to preheat the straw, and the material is released into the atmospheric pressure container 5 with water inside;

[0047] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com