Method for synthesizing ZSM-48 zeolite through solvent-free solid-phase synthesis

A ZSM-48, solid-phase synthesis technology, applied in chemical instruments and methods, inorganic chemistry, molecular sieves and alkali exchange compounds, etc., can solve problems such as low synthesis efficiency, limited application, safety hazards, etc. Crystallinity and purity, loss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: Solvent-free solid-phase synthesis ZSM-48 zeolite

[0023] Grind 1.6g of solid silica gel, 0.8g of ammonium fluoride, and 1g of organic template (T) in a grinding mill, and then crystallize at 180°C for 4 days to complete the crystallization. The product is suction filtered and dried to obtain ZSM- 48 Zeolite products.

[0024] The molar ratio of the reaction raw materials is as follows: 1SiO 2 :0.8NH 4 F:0.3T

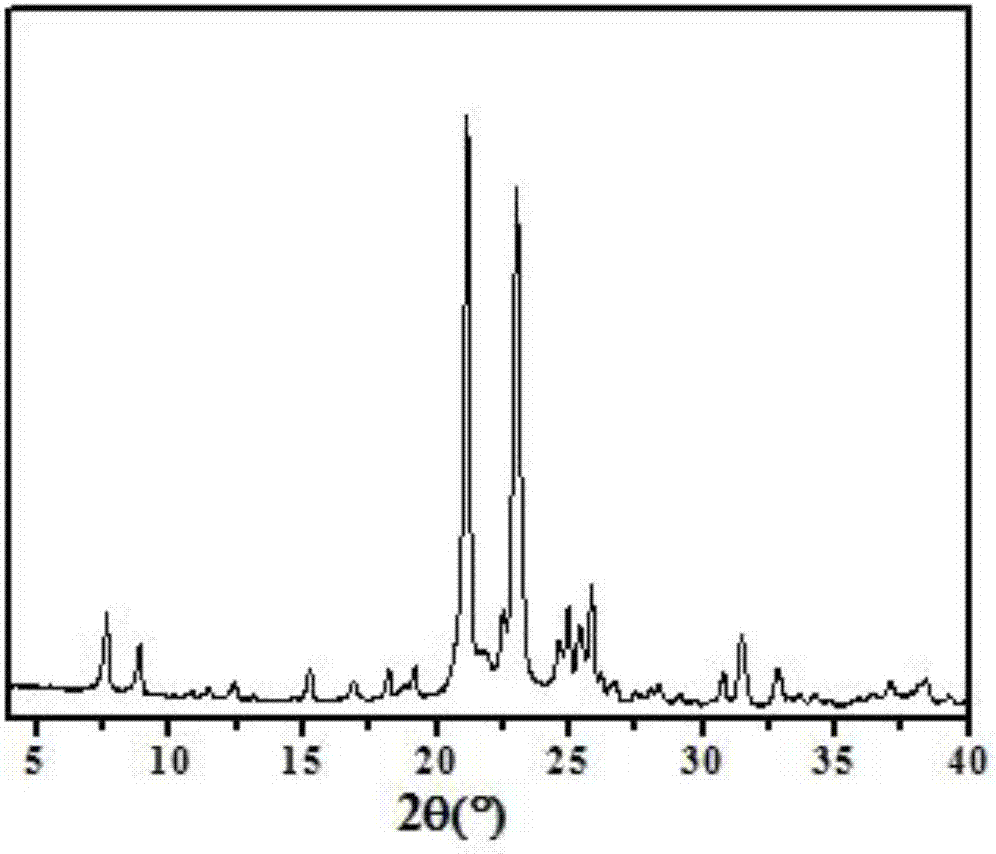

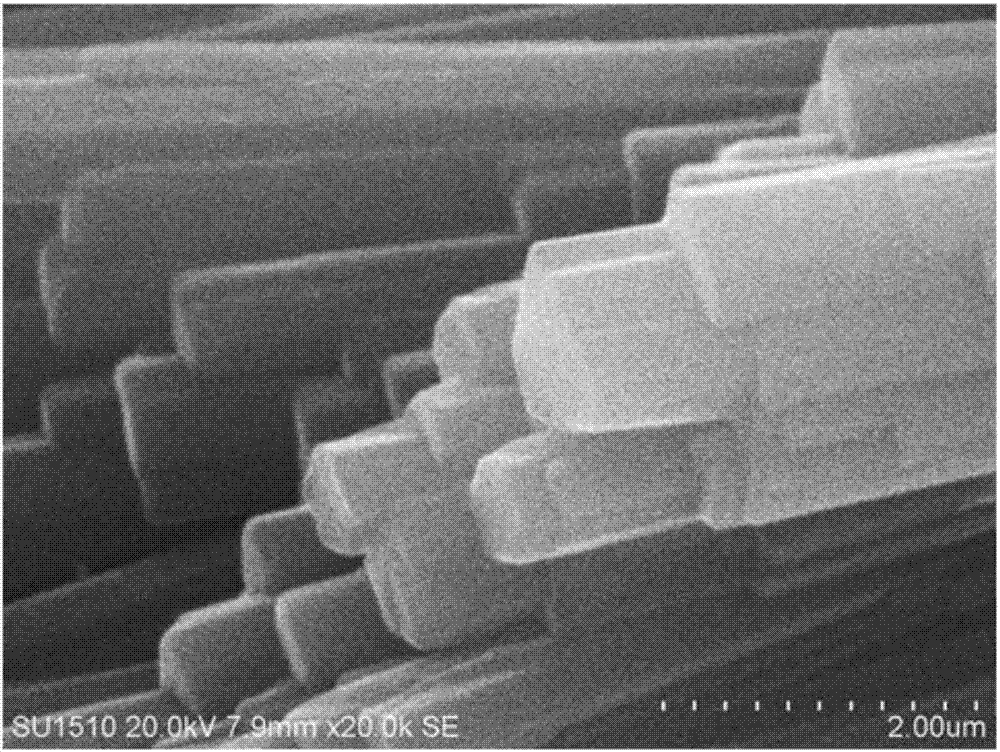

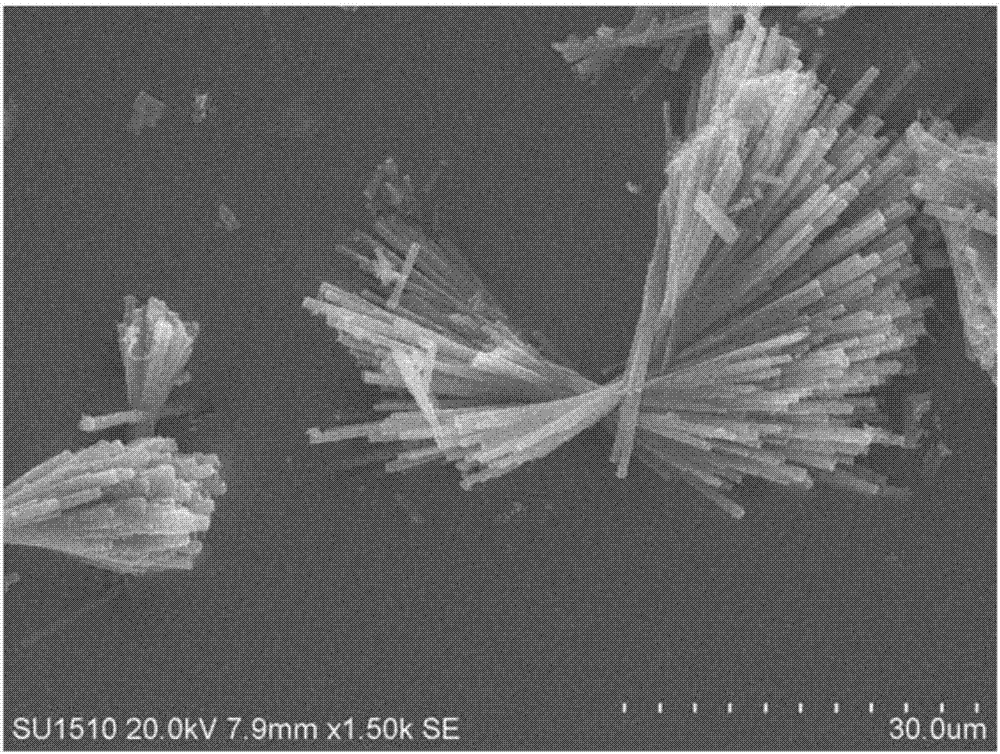

[0025] Through XRD analysis, its structure of the product that obtains is ZSM-48 zeolite ( figure 1 ), and find out by SEM photo, the ZSM-48 zeolite that this method obtains is the morphology of long rod ( figure 2 and image 3 ).

Embodiment 2

[0026] Embodiment 2: Solvent-free solid-phase rapid synthesis of ZSM-48 zeolite

[0027] Put 1.6g of white carbon black, 0.5g of ammonium fluoride, 0.33g of organic template and 0.1g of ZSM-48 seeds in a grinding mill, and then crystallize at 200°C for 1 day to completely crystallize, and the product is suction filtered. After drying, the ZSM-48 zeolite product can be obtained.

[0028] The molar ratio of the reaction raw materials is as follows: 1SiO 2 :0.5NH 4 F:0.1T

Embodiment 3

[0029] Embodiment 3: Solvent-free solid-phase synthesis of aluminum-containing ZSM-48 zeolite

[0030] Grind 1.6g of solid silica gel, 0.2g of boehmite, 1g of ammonium fluoride, and 0.5g of organic template in a grinding mill, and then crystallize at 160°C for 6 days to complete crystallization. The product is suction filtered and dried A ZSM-48 zeolite product is available.

[0031] The molar ratio of the reaction raw materials is as follows: 1SiO 2 :0.8NH 4 F:0.05Al 2 o 3 :0.15T

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com