A kind of preparation method of high-energy low-explosion temperature nitrocellulose

A nitrocellulose and explosion temperature technology, applied in organic chemistry and other directions, can solve the problems of large shooting smoke, endanger the safety of the environmental shooter, and low temperature, and achieve the effect of less smoke and flame, improving the probability of self-survival, and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

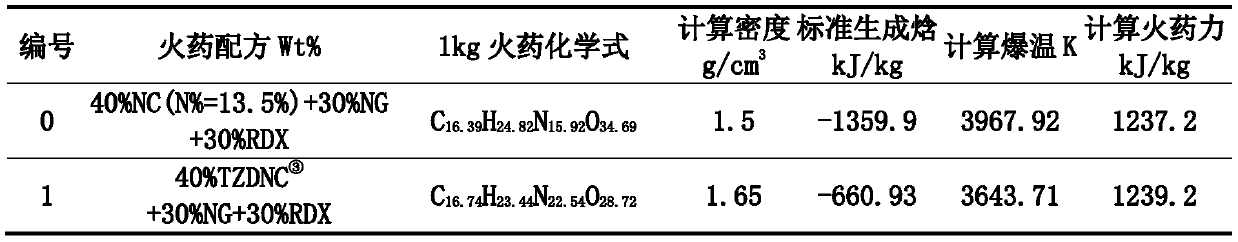

Examples

Embodiment 1

[0033] 1), the synthesis of dipotassium azobistetrazolium

[0034] A certain amount of KOH is made into a solution of 0.15-0.18mol / L, and then according to the ratio of the amount of substances, pentaaminotetrazole is added in a ratio of KOH: pentaaminotetrazole=(2.3-2.6):1, and then at 70 Stir at ℃~80℃ for 20~30min, then slowly add KMnO with a ratio of 0.7~0.85 to pentaaminotetrazole 4 , react for 4-5 hours, then add ethanol equal to the volume of KOH solution, boil for 2-3 minutes, filter while hot to obtain the filtrate, freeze and filter to obtain a yellow needle-like solid, dry to obtain dipotassium azobistetrazolium.

[0035] 2), the synthesis of ethyl azobistetrazolium diacetate

[0036] Dissolve the obtained dipotassium azobistetrazolium completely in methanol, and then add BrCH with a molar ratio of 3 to 3.2 to the dipotassium azobistetrazolium substance 2 COOC 2 h 5 , reacted for 12 hours, and then heated to reflux around 90-110°C. Take out and spin dry to obtai...

Embodiment 2

[0042] 1), the synthesis of N, N-two tetrazole potassium amines

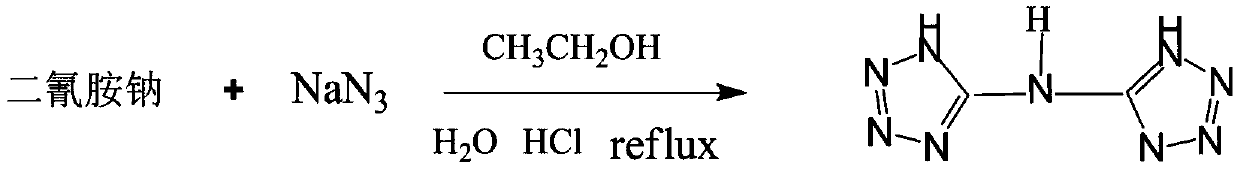

[0043]Dissolve sodium dicyanamide and sodium azide in ethanol solution at a ratio of 1:1 according to the following formula, adjust the pH to 6-7 with HCI solution, react at 60°C for 12 hours, spin dry, wash with water, and dry by spin Get N, N-two tetrazolium amine.

[0044]

[0045] Then dissolve the prepared N,N-bistetrazole amine in ethanol, slowly add KMnO4 with a substance ratio of 1.8-2 to N,N-bistetrazole amine at 60°C, and react for 3-4 hours, Raise the temperature to 80°C and keep for 3-5 minutes, filter while hot to obtain the filtrate, freeze and filter to obtain a solid, and dry to obtain N,N-bistetrazole potassium amine.

[0046] 2), the synthesis of N, N two tetrazole ethyl diacetate

[0047] Dissolve the obtained N,N di-tetrazole potassium amine completely in methanol, and then add BrCH with a ratio of 3 to 3.2 to N,N di-tetrazole methyl amine 2 COOC 2 h 5 , reacted for 12 hours, and then...

Embodiment 3

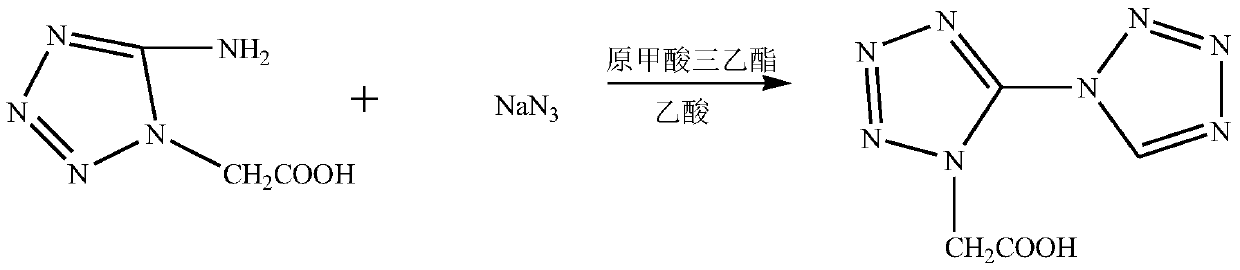

[0053] 1) Synthesis of 5,1'-tetrazole-1-acetic acid:

[0054]

[0055] Aminotetrazoleacetic acid and sodium azide were reacted in a 1:1 mixed solution of triethyl orthoformate and acetic acid at 80°C for 12 hours according to the ratio of substances of 1:1, spin-dried, washed with water, and dried by filtration to obtain 5 , 1'-Bitrazol-1-acetic acid.

[0056] 2) Preparation of nitrocellulose grafted with 5,1'-tetrazole-1-acetic acid

[0057] Add the 5,1'-bitetrazol-1-acetic acid prepared in the previous step to the microcrystalline cellulose substance at a ratio of 1 / 4 to 1 / 3 to the N,N-dimethylacetamide dissolved The microcrystalline cellulose solution is added with anhydrous LiCl in an amount of 0.9 to 1 in a molar ratio to the microcrystalline cellulose substance, and after stirring at 60 to 70°C for 24 hours, then added in a molar ratio to the microcrystalline cellulose substance of 2 to 2.2 HNO3, after reacting for 6-7 hours, drop KOH until the solution is neutral, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com