Production method of white granulated sugar

A production method, white granulated sugar technology, applied in the direction of using adsorbent purification, etc., to achieve the effect of reducing SO2 content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

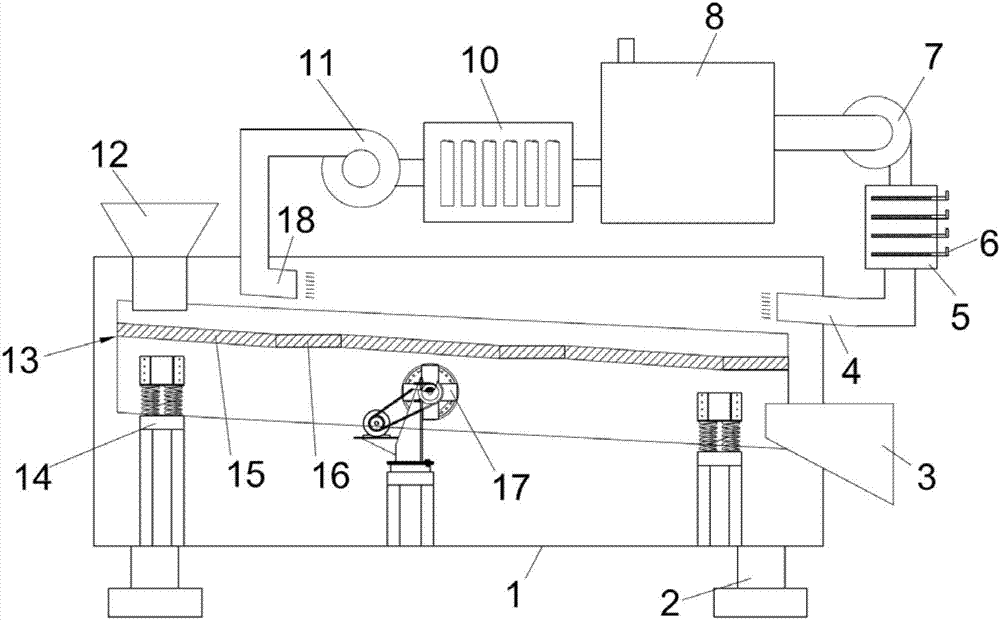

Image

Examples

Embodiment 1

[0025] The method for producing white granulated sugar of the present invention includes the following steps: filtering the sugarcane juice to obtain clear juice, then mixing the clear juice and phosphoric acid in a juice mixing box, heating the mixed mixed juice to 78°C and adding the sub Sodium bisulfate and polydimethyldiallylammonium chloride; then pass into the first-stage reactor and add lime milk and calcium saccharification to fully mix, and then pass the syrup obtained by mixing in the first-stage reactor into Add chitosan and cationic acrylic amide to the secondary reactor and mix thoroughly, heat the syrup obtained by mixing in the secondary reactor to 95°C, and then pass it to the settler to settle, and the clear juice that passes through the settler is then obtained through the separation system Clear syrup, evaporate, crystallize, separate honey and cool and dry the clear syrup to obtain white granulated sugar.

[0026] The said separation system adopts an ultrafilt...

Embodiment 2

[0029] The method for producing white granulated sugar of the present invention includes the following steps: filtering the sugarcane juice to obtain clear juice, then mixing the clear juice and phosphoric acid in a juice mixing box, heating the mixed mixed juice to 75°C and adding the sub Sodium bisulfate and polydimethyldiallylammonium chloride; then pass into the first-stage reactor and add lime milk and calcium saccharification to fully mix, and then pass the syrup obtained by mixing in the first-stage reactor into Add chitosan and cationic acrylic acid amide to the secondary reactor and mix thoroughly. The syrup obtained by mixing in the secondary reactor is heated to 105°C, and then passed into the settler to settle, and the clear juice after passing through the settler is obtained through the separation system Clear syrup, evaporate, crystallize, separate honey and cool and dry the clear syrup to obtain white granulated sugar.

[0030] The said separation system adopts an ...

Embodiment 3

[0033] The method for producing white granulated sugar of the present invention includes the following steps: filtering the sugarcane juice to obtain clear juice, then mixing the clear juice and phosphoric acid in a juice mixing box, heating the mixed mixed juice to 80°C and adding the sub Sodium bisulfate and polydimethyldiallylammonium chloride; then pass into the first-stage reactor and add lime milk and calcium saccharification to fully mix, and then pass the syrup obtained by mixing in the first-stage reactor into Add chitosan and cationic acrylic acid amide to the secondary reactor and mix thoroughly. The syrup obtained by mixing in the secondary reactor is heated to 90°C, and then passed into the settler to settle, and the clear juice after passing through the settler is obtained through the separation system. Clear syrup, evaporate, crystallize, separate honey and cool and dry the clear syrup to obtain white granulated sugar.

[0034] The said separation system adopts an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com