Preparation method of copper nanosheet/zinc oxide nanosheet composite material and application

A zinc oxide nanometer and composite material technology is applied in the field of preparation of nano copper sheet/zinc oxide nanosheet composite material, which can solve the problems of low utilization rate of sunlight and high recombination rate of zinc oxide electrons and holes, and achieves the operation method. Simple, broad development prospects and practical application space, the effect of few synthesis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

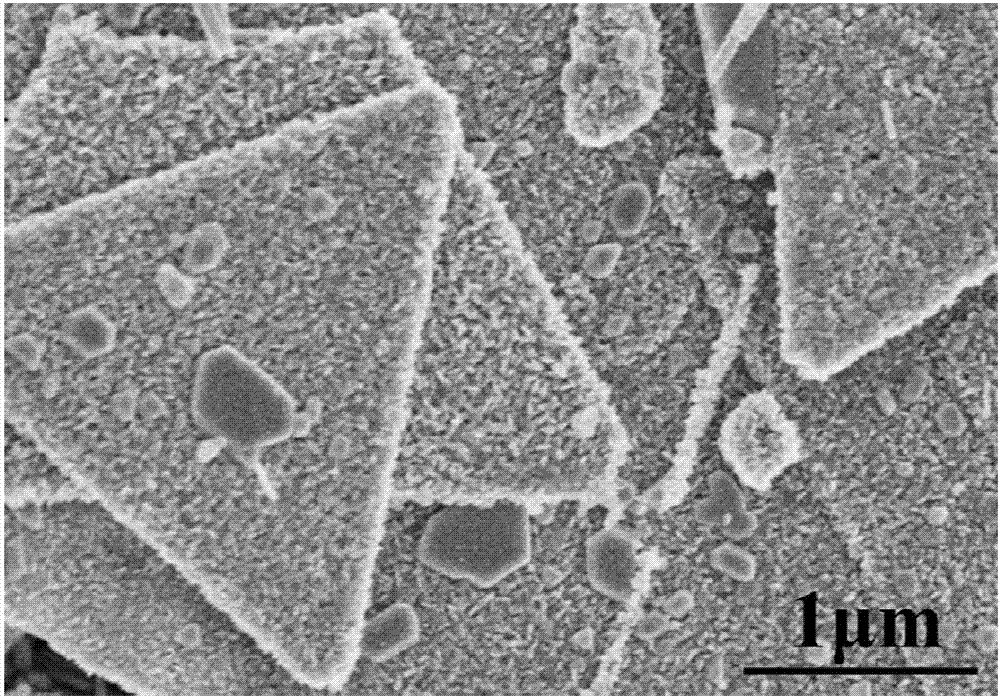

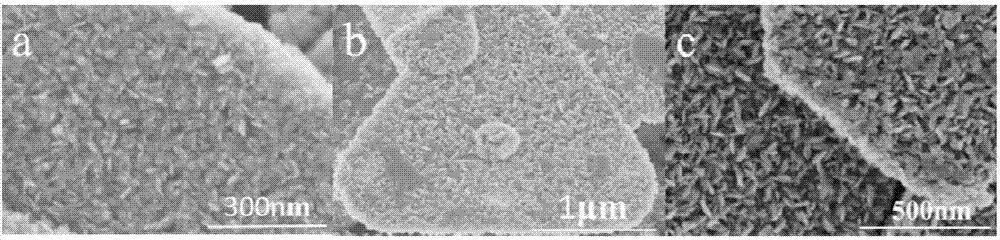

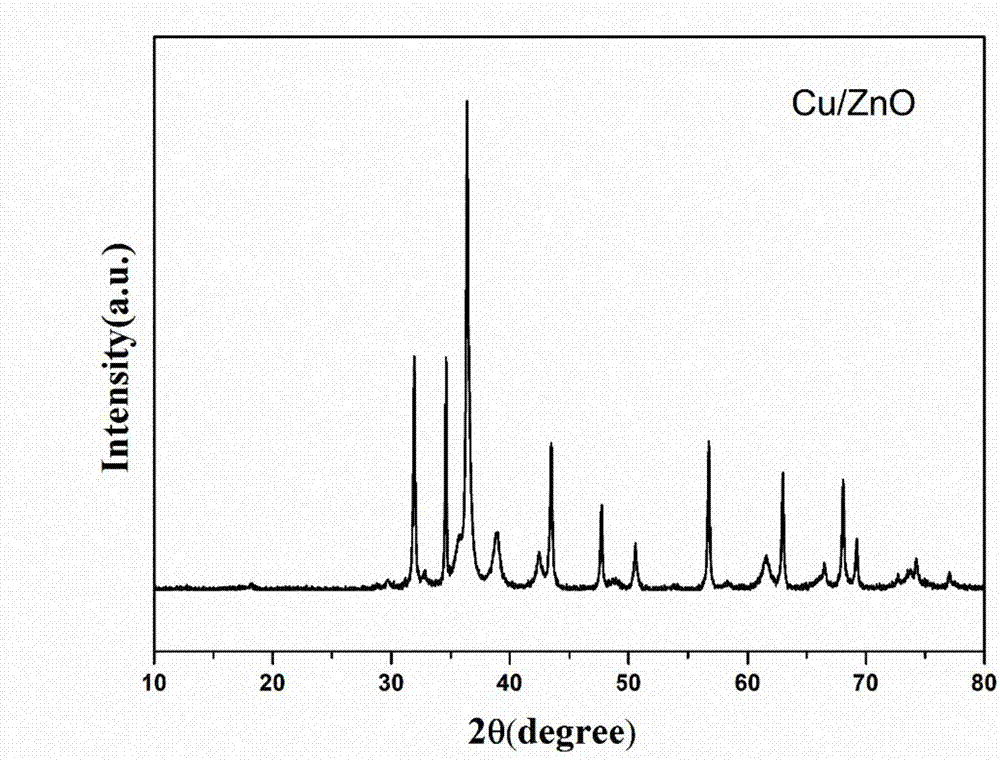

[0032] A method for preparing a nano-copper flake / zinc oxide nano-flake composite material having a strong degradation effect on rhodamine B and methyl orange, the specific steps are as follows:

[0033] (1) Synthesis of nano-copper flakes: First, 0.1 mmol of copper bromide was dissolved in distilled water, ultrasonically dissolved, and magnetically stirred. Add 0.05 mmol CTAB (cetyltrimethylammonium bromide), and stir magnetically. Add 2mmolVC (ascorbic acid), and magnetically stir. Slowly add 2ml of 0.5mol / L NaOH solution dropwise and stir. Finally, transfer it to the liner of a polytetrafluoroethylene reactor, and heat it with water at 110° C. for 1 hour. After naturally cooling to room temperature, the product was collected, washed several times with distilled water and ethanol, and centrifuged. Finally, it was dried in a vacuum oven for further characterization.

[0034] (2) Preparation of seed crystal solution: Weigh 0.2094g of zinc acetate, dissolve it in 120ml of a...

Embodiment 2

[0042] A method for preparing a nano-copper flake / zinc oxide nano-flake composite material having a strong degradation effect on rhodamine B and methyl orange, the specific steps are as follows:

[0043] (1) Synthesis of nano-copper flakes: First, 0.1 mmol of copper bromide was dissolved in distilled water, ultrasonically dissolved, and magnetically stirred. Add 0.05 mmol CTAB (cetyltrimethylammonium bromide), and stir magnetically. Add 2mmolVC (ascorbic acid), and stir magnetically. Slowly add 2ml of 0.5mol / L NaOH solution dropwise and stir. Finally, transfer it to the liner of a polytetrafluoroethylene reactor, and heat it with water at 110° C. for 1 hour. After naturally cooling to room temperature, the product was collected, washed several times with distilled water and ethanol, and centrifuged. Finally, it was dried in a vacuum oven for further characterization.

[0044] (2) Preparation of seed crystal solution: Weigh 0.2094g of zinc acetate, dissolve it in 120ml of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com