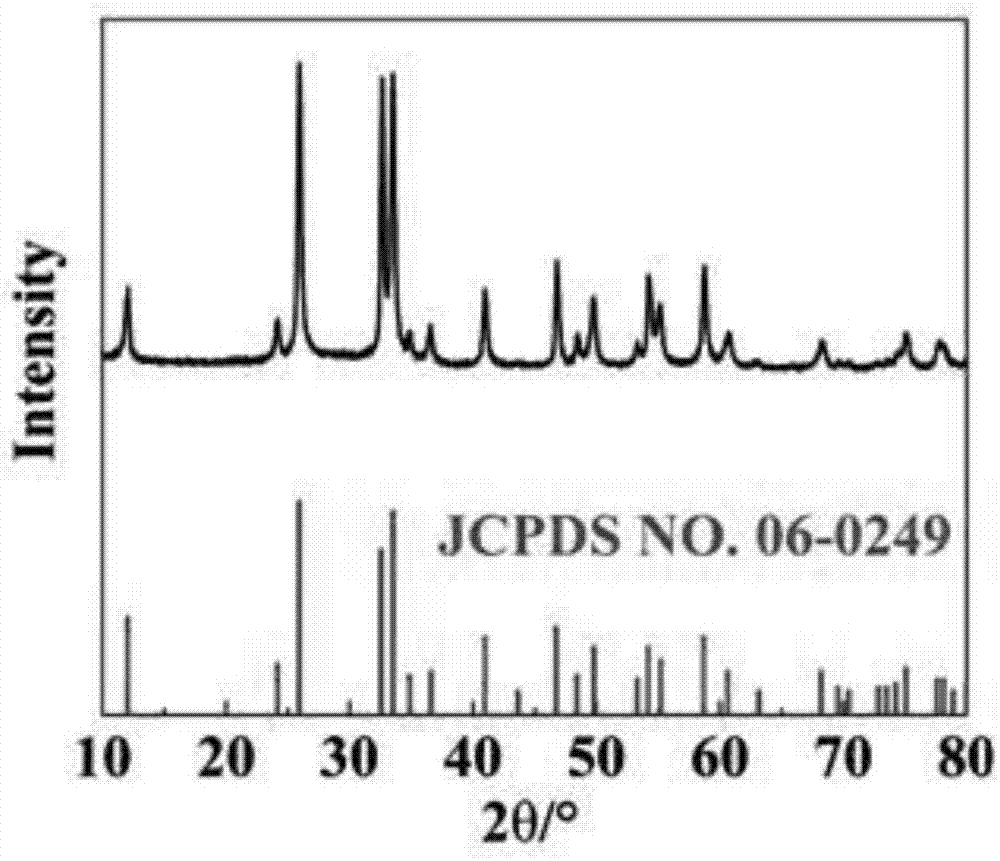

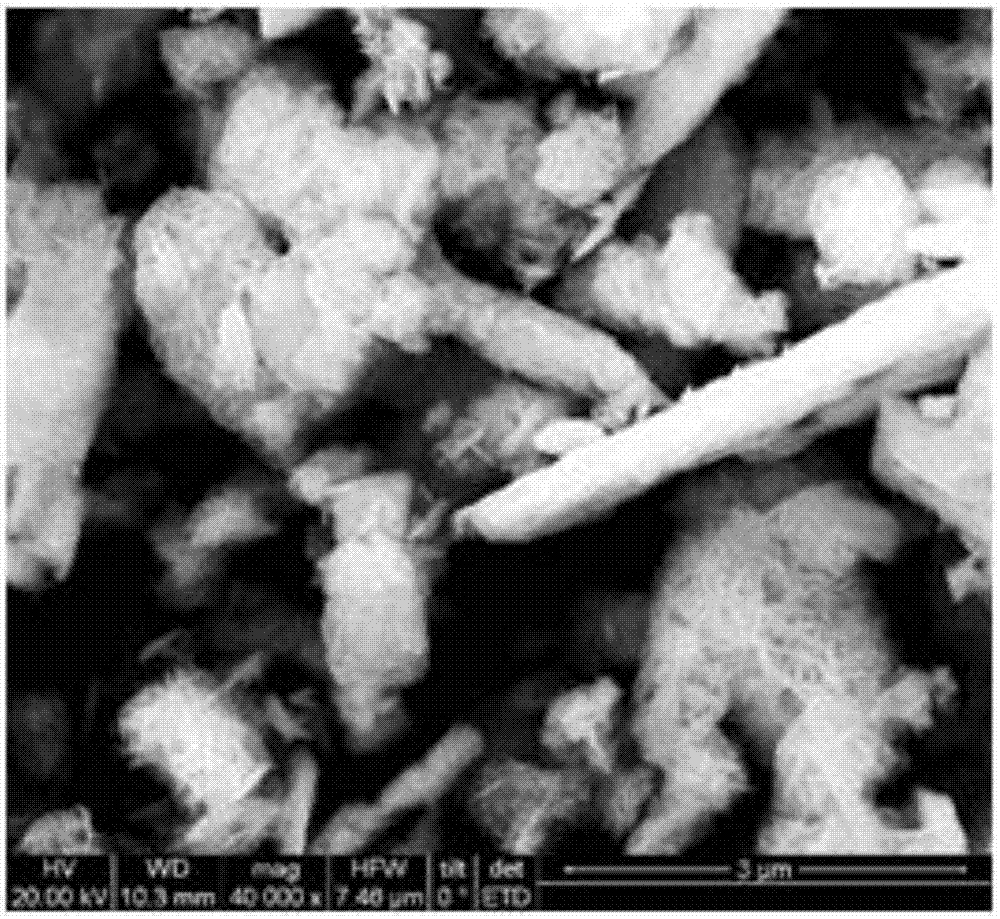

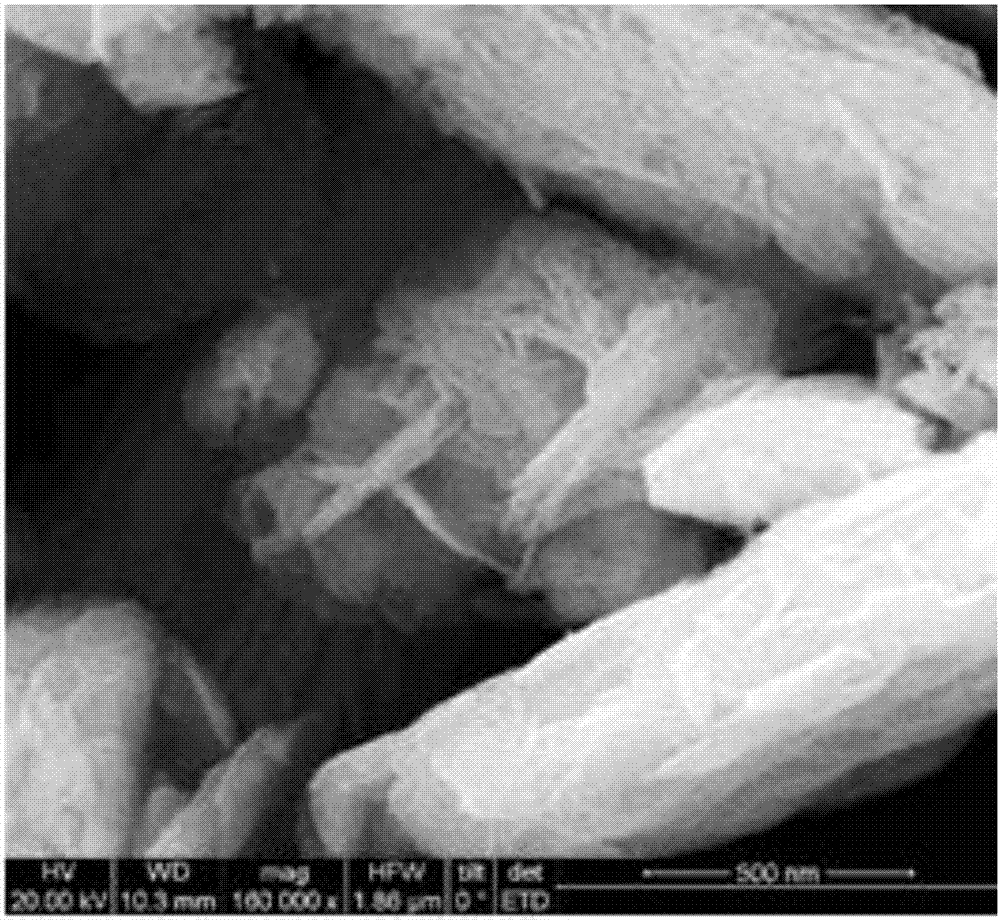

Preparation method of BiOCl nanometer photocatalyst, prepared photocatalyst, and application of prepared photocatalyst

A nano-photocatalyst and photocatalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, inorganic chemistry, etc., can solve the problems of easy precipitation of copper ions, cumbersome operation, pollution and waste, and achieve low requirements for preparation equipment, The effect of convenient operation and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment B

[0028] The preparation method of BiOCl nanometer photocatalyst of the embodiment of the present invention, described method comprises the following steps:

[0029] (1) Dissolve bismuth nitrate and sodium carboxymethylcellulose in water, stir evenly to obtain a bismuth-containing mixed solution; the mass dosage ratio of described bismuth nitrate and sodium carboxymethylcellulose is: (0.3-5): 1; the viscosity of the sodium carboxymethylcellulose is: 200-500mPas;

[0030] (2) Adding chloride solution dropwise to the mixed solution obtained in step (1), stirring evenly to obtain a bismuth-containing precursor solution;

[0031] (3) Adjust the pH value of the bismuth-containing precursor solution obtained in step (2) to 5.0-6.5, and stir to form a reactant evenly;

[0032] (4) Reacting the reactant obtained in step (3) at 150-160° C. for 24-30 h to obtain a precipitate; (5) washing and drying the precipitate obtained in step (4) to obtain BiOCl powder.

[0033] The source of bism...

Embodiment 1

[0040] Weigh the Bi(NO 3 ) 3 ·5H 2O and 0.1g sodium carboxymethylcellulose (viscosity: 200-500mPa s) in a beaker, dissolve it with 25mL deionized water and make it mix uniformly to obtain a mixed solution containing bismuth, weigh 2.238gKCl and join in 150ml ultrapure water , ultrasonicated for 30 min, and stirred until uniform to obtain a KCl solution. Slowly titrate 5ml of the prepared KCl solution into the bismuth-containing mixed solution, stir evenly to form a bismuth-containing precursor solution; weigh 5.611g of KOH, dissolve it in 50ml of deionized water, and set aside; use the above-prepared KOH Solution Adjust the pH of the bismuth-containing precursor solution to 6.0, transfer all the bismuth precursor solution to a polytetrafluoroethylene high-pressure reactor, and then put the reactor into an oven at 160°C, and heat it at a constant temperature for 24 hours to obtain precipitation; The precipitate was washed several times with deionized water and ethanol, and t...

Embodiment 2

[0045] Weigh the Bi(NO 3 ) 3 ·5H 2 0 and 0.3g sodium carboxymethylcellulose (viscosity: 200-500mPa s) in a beaker, dissolve it with 25mL deionized water and make it mix uniformly to obtain a mixed solution containing bismuth, weigh 2.238gKCl and join in 150ml ultrapure water , ultrasonicated for 30 min, and stirred until uniform to obtain a KCl solution. Slowly titrate 5ml of the prepared KCl solution into the bismuth-containing mixed solution, stir evenly to form a bismuth-containing precursor solution; weigh 5.611g of KOH, dissolve it in 50ml of deionized water, and set aside; use the above-prepared KOH Solution Adjust the pH of the bismuth-containing precursor solution to 6.0, transfer all the bismuth precursor solution to a polytetrafluoroethylene high-pressure reactor, and then put the reactor into an oven at 160°C, and heat it at a constant temperature for 24 hours to obtain precipitation; The precipitate was washed several times with deionized water and ethanol, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com