Method for in-situ preparation of g-C3N4-TiO2 nano heterojunction photocatalyst film

A photocatalytic film, g-c3n4-tio2 technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of poor film stability, difficult recycling, complex composite methods, etc. , to achieve the effect of stable structure, uniform distribution and favorable mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

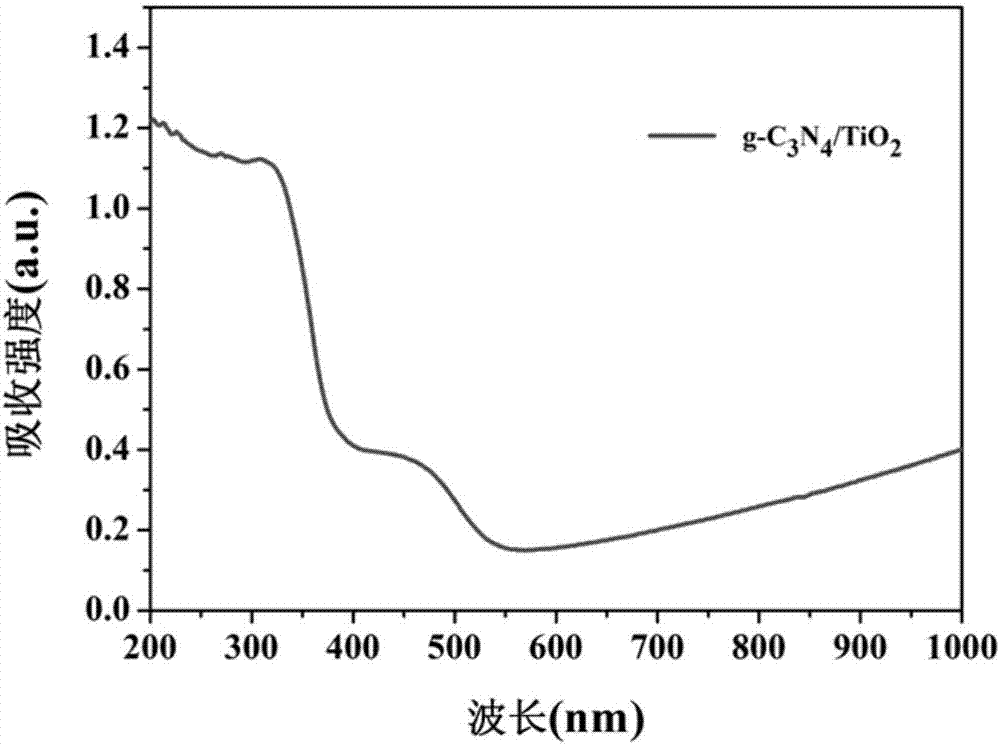

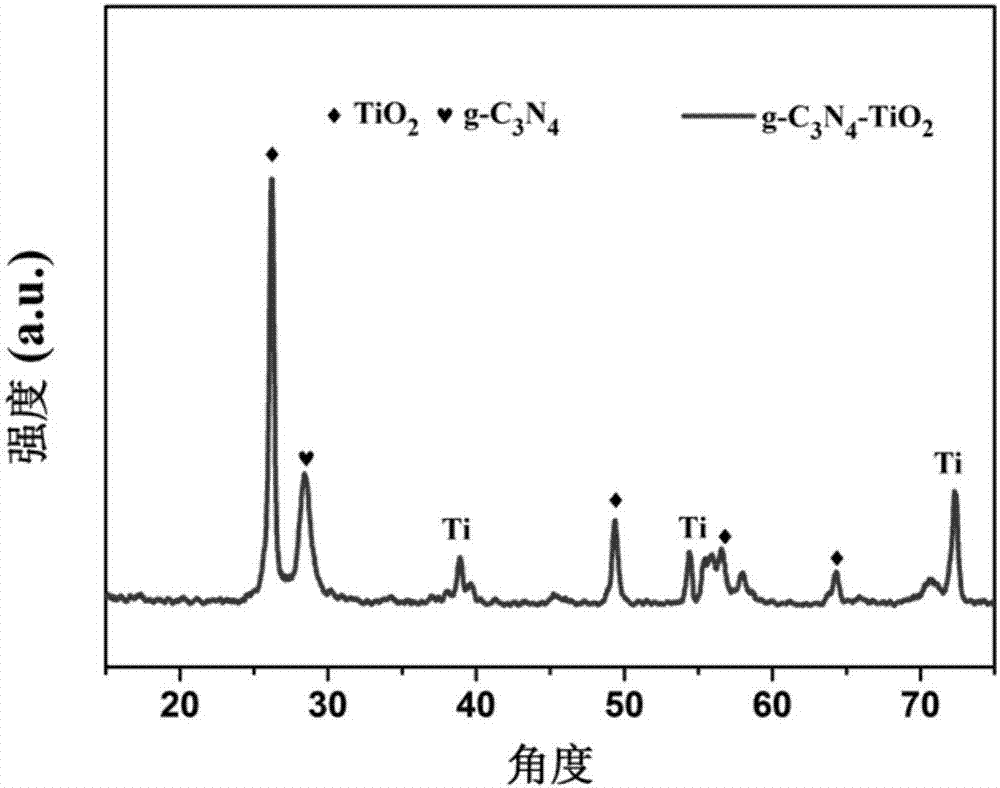

[0035] At room temperature, 0.5g NaOH, 0.7g KOH, 25mL ethylene glycol and 25mL deionized water were stirred for 1 hour to obtain a mixed solution, which was transferred to a 100mL polytetrafluoroethylene-lined reactor, and titanium The slice (21mm×42mm) was immersed in the above reaction solution, and kept at 160°C for 72h. After the reaction solution was cooled to room temperature, the titanium sheet was taken out, rinsed repeatedly with ethanol and water, then acidified in 0.5 wt% hydrochloric acid aqueous solution for 24 hours, and TiO2 was obtained after drying. 2 Precursor nanofilms. TiO 2 Precursor nano film and 0.5g melamine were placed in a crucible together, then placed in a microwave muffle furnace, heated to 550°C at a heating rate of 30°C / min, kept for 0.1h, and then naturally cooled to room temperature to obtain g-C 3 N 4 -TiO 2 Nano-heterojunction photocatalytic composite thin film. Its UV-Vis absorption spectrum and XRD pattern are shown in figure 1 and ...

Embodiment 2

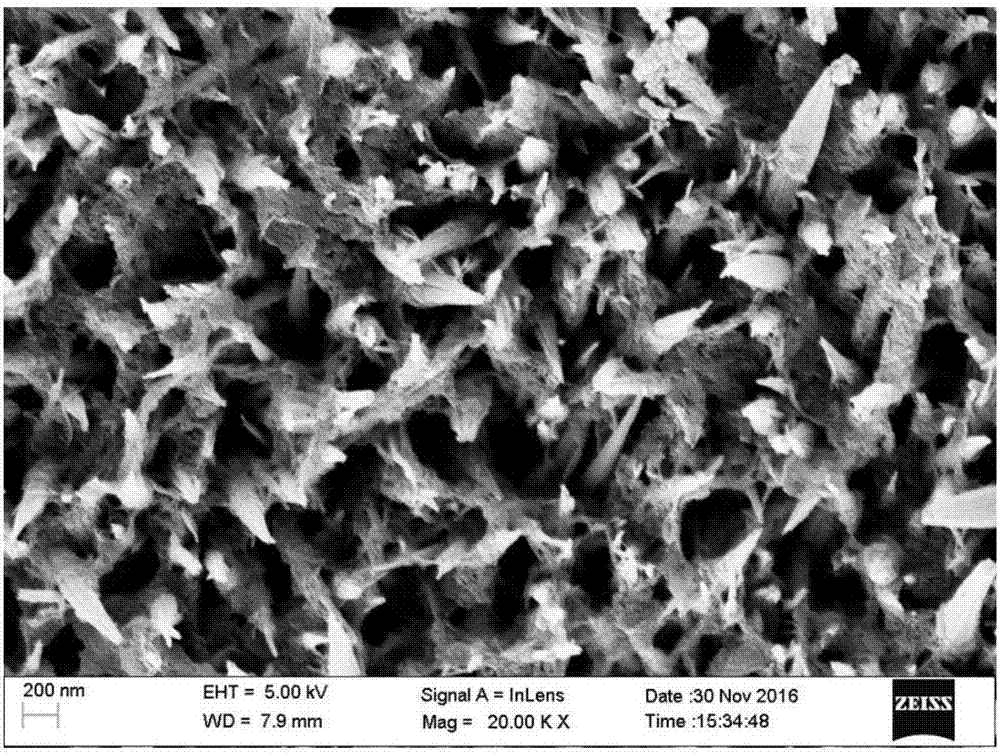

[0037] At room temperature, 1.0g NaOH, 1.4g KOH, 25mL glycerin and 25mL deionized water were stirred for 1h to obtain a mixed solution, which was transferred to a 100mL polytetrafluoroethylene-lined reactor, and the titanium The slice (21mm×42mm) was immersed in the above reaction solution, and kept at 180°C for 12h. After the reaction solution was cooled to room temperature, the titanium sheet was taken out, rinsed repeatedly with ethanol and water, and then acidified in 0.5wt% nitric acid aqueous solution for 24 hours, and TiO2 was obtained after drying. 2 Precursor nanofilms. TiO 2 Precursor nano film and 2.0g melamine were placed in a crucible together, then placed in a microwave muffle furnace, heated to 600°C at a heating rate of 20°C / min and kept for 0.25h, and then naturally cooled to room temperature to obtain g-C 3 N 4 -TiO 2 Nano-heterojunction photocatalytic composite thin film. It looks like Figure 4 As shown, the composite film has a pore structure, and th...

Embodiment 3

[0039] At room temperature, 0.5g NaOH, 2.1g KOH, 25mL ethylene glycol and 25mL deionized water were stirred for 1 hour to obtain a mixed solution, which was transferred to a 100mL polytetrafluoroethylene-lined reactor, and titanium The slice (21mm×42mm) was immersed in the above reaction solution, and kept at 220°C for 3h. After the reaction solution was cooled to room temperature, the titanium sheet was taken out, rinsed repeatedly with ethanol and water, then acidified in 0.3 wt% aqueous sulfuric acid solution for 24 hours, and TiO2 was obtained after drying. 2 Precursor nanofilms. TiO 2 Precursor nano film and 3.0g melamine were placed in a crucible together, then placed in a microwave muffle furnace, heated to 650°C at a heating rate of 15°C / min, kept for 0.5h, and then naturally cooled to room temperature to obtain g-C 3 N 4 -TiO 2 Nano-heterojunction photocatalytic composite thin film. It looks like Figure 5 As shown, the composite film has a pore structure, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com