Chitosan-platinum nano particle simulation oxidase

A technology of platinum nanometer and chitosan, which is applied in the nanometer field to achieve the effect of efficiently simulating the activity of oxidase, and the preparation process is simple and fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

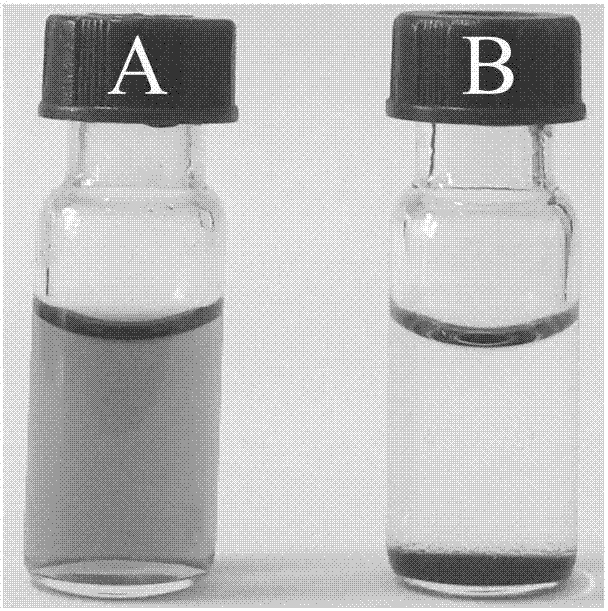

[0034] Weigh 0.1 g of chitosan and dissolve it in 50 mL of acetic acid with a concentration of 1% (v / v), and stir for 15 minutes to completely dissolve the chitosan to obtain a chitosan solution with a concentration of 0.2% (m / v). Add 2 mL of 10 mmol / L chloroplatinic acid to 47 mL of 0.2% (m / v) chitosan solution, stir for 30 minutes, and then add 1 mL of freshly prepared 0.2 mol / L chitosan solution dropwise. Sodium borohydride solution (completely added within 5 minutes), placed in the dark and stirred for 90 minutes to obtain a dark brown chitosan-platinum nanoparticle solution. Place chitosan-platinum nanoparticles and platinum nanoparticles without chitosan protection (i.e. bare platinum nanoparticles) at room temperature for 7 days, the results are as follows: figure 1 shown. As can be seen from the figure, after being placed at room temperature for 7 days, the chitosan-platinum nanoparticle solution was uniform and stable without precipitation (see figure 1 Panel A in t...

Embodiment 2

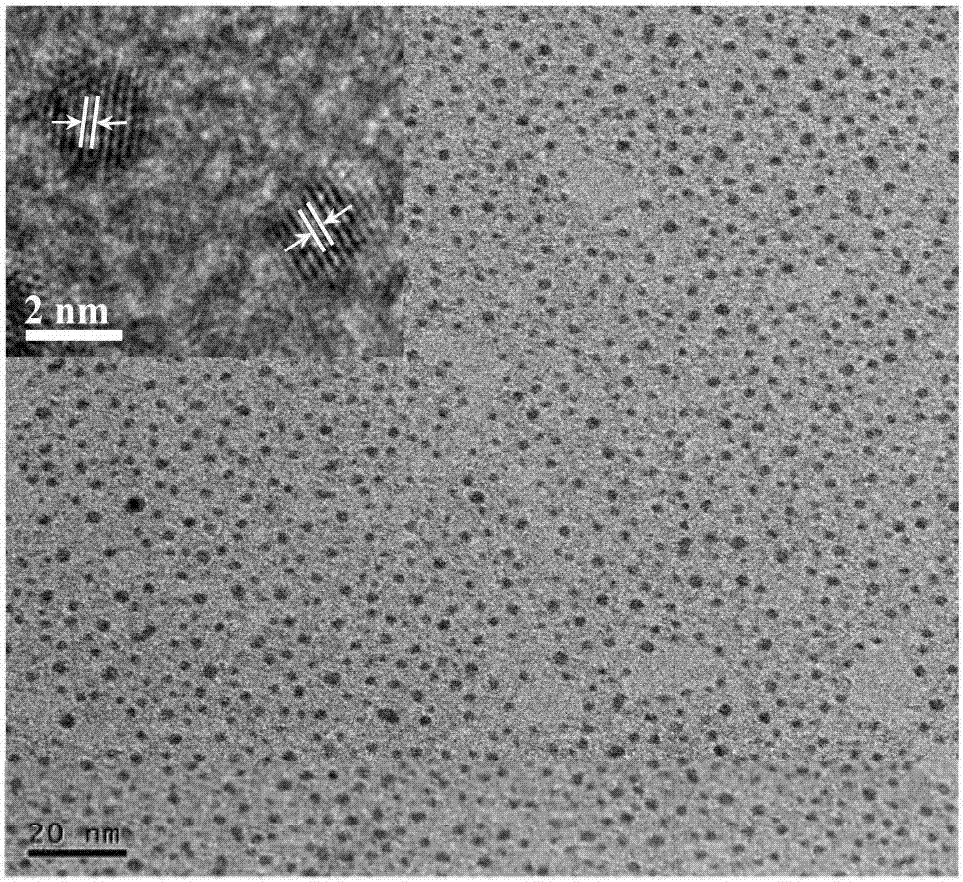

[0036] The chitosan-platinum nanoparticle solution prepared in Example 1 was drop-coated on a copper grid for transmission electron microscope testing. The results showed that the chitosan-platinum nanoparticles had an average particle size of 2.1 ± 0.3 nm (see figure 2 ). The interplanar spacing of the resulting nanoparticles is 0.224 nm, corresponding to the 111 crystal plane of the platinum crystal (see figure 2 illustration in ).

Embodiment 3

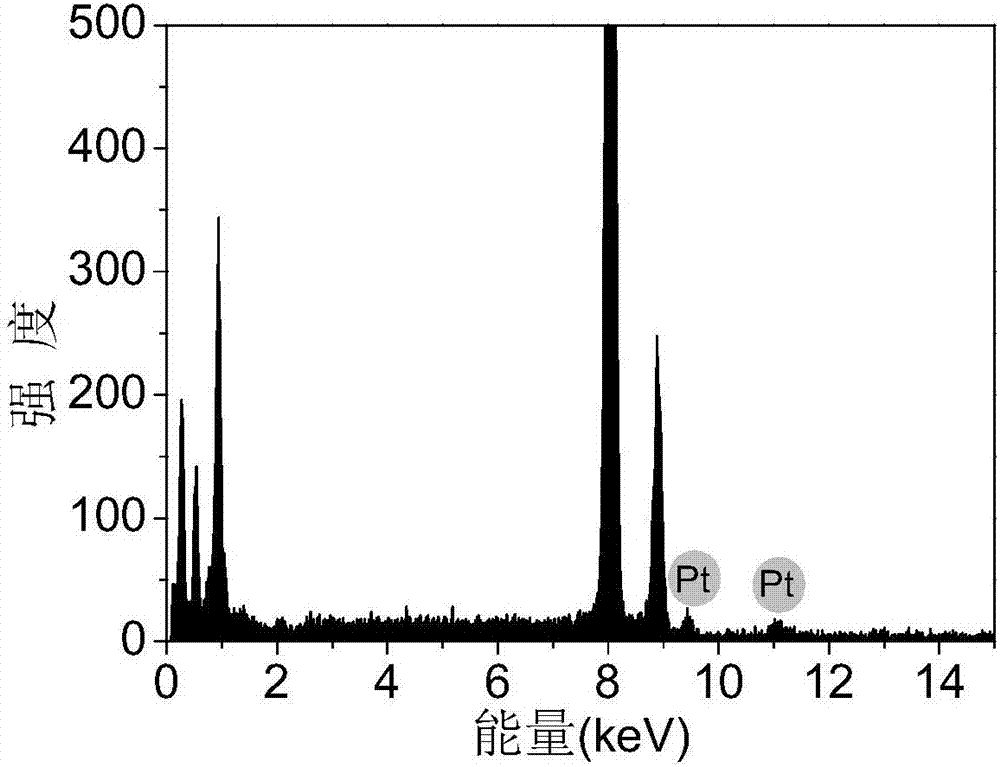

[0038] The chitosan-platinum nanoparticle solution obtained in Example 1 is freeze-dried to obtain powder, and the obtained powder is taken for elemental analysis (see image 3 ). The results showed that the obtained nanoparticles contained platinum element.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| lattice spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com