Reflective thermal-insulation coating stone-like paint and preparation method thereof

A technology of real stone paint and weight percentage, which is applied to exterior wall decoration coatings, reflective heat insulation plastering real stone paint, and the field of preparing the real stone paint, which can solve the problem of high construction environment requirements, poor wall insulation effect, and high spray pressure. and other problems, to meet the requirements of reducing the quality of construction personnel and construction conditions, better reflection and heat insulation effect, and reduce the power consumption of air conditioners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Example 1: Preparation of a reflective and heat-insulating plastered real stone paint

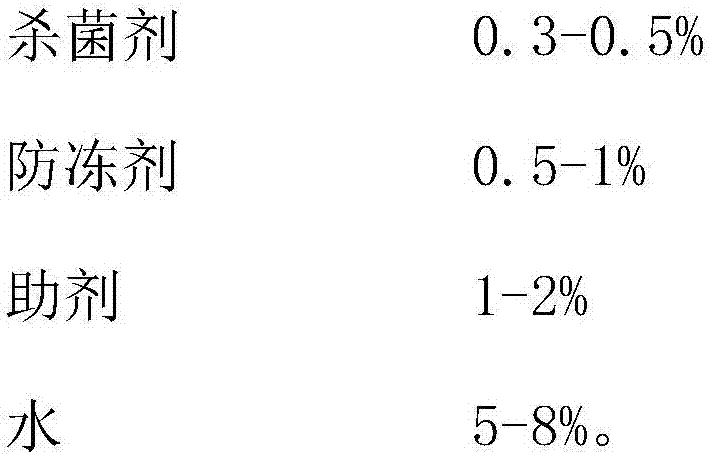

[0057] Table 1 embodiment 1-3 reflective heat-insulating plaster real stone paint formula table (w / w%)

[0058]

Example 1

Example 2

Example 3

Natural colored sand

65

55

59

19

25

19

hollow glass microspheres

5

9

10

Protective Colloidal Salt

1

2

1.5

0.5

0.5

0.5

0.3

0.3

0.3

1

0.8

0.8

Auxiliary

1

2

2

water

7.2

5.4

6.9

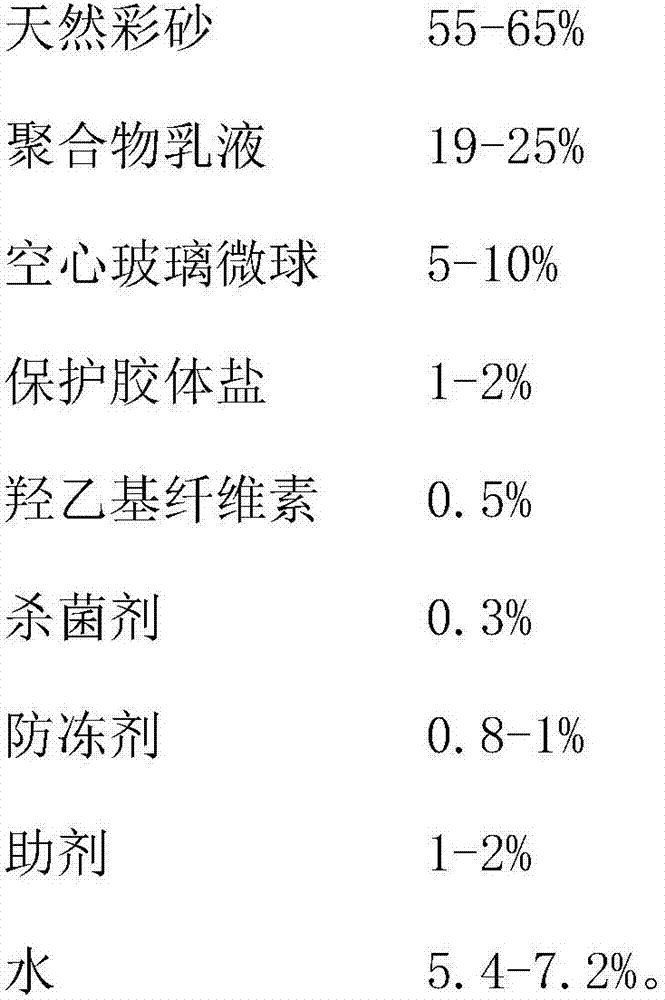

[0059] The raw material formula is shown in Table 1, wherein:

[0060] The particle size of natural colored sand is 40-120 mesh; the polymer emulsion is acrylic pure acrylic emulsion; the hollow glass microspheres are produced by 3M Company, and the model is VS5500 hollow glass microspheres; the protective colloid salt is LAPONITE- S482; hydrox...

Embodiment 2

[0068] Example 2: Preparation of a reflective and heat-insulating plastered real stone paint

[0069] The raw material formula is shown in Table 1, wherein:

[0070] The particle size of natural colored sand is 40-120 mesh; the polymer emulsion is acrylic silicon acrylic emulsion; the hollow glass microspheres are hollow glass microspheres produced by 3M Company, the model is S15; the protective colloid salt is LAPONITE- RDS; hydroxyethyl cellulose is a non-ionic water-soluble cellulose ether; the antifreeze is glycerol; the bactericide is an isothiazolinone bactericide; The thickener is a mixture of 10:10:2:5 by mass, the coalescent is a mixture of dipropylene glycol monomethyl ether and diethylene glycol butyl ether; the defoamer is a mineral oil defoamer; the thickener It is a polyacrylate alkali swelling thickener.

[0071] The preparation method is the same as in Example 1.

Embodiment 3

[0072] Example 3: Preparation of a reflective and heat-insulating plastered real stone paint

[0073] The raw material formula is shown in Table 1, wherein:

[0074] The particle size of natural colored sand is 40-120 mesh; the polymer emulsion is acrylic silicon acrylic emulsion; the hollow glass microspheres are hollow glass microspheres produced by 3M Company, the model is S15; the protective colloid salt is LAPONITE- RDS; Hydroxyethyl cellulose is non-ionic water-soluble cellulose ether; Antifreeze is propylene glycol; The thickener is a mixture of 10:10:2:5 by mass; the defoamer is mineral oil defoamer; the thickener is polyacrylic acid salt-alkali swelling type thickener; the film-forming aid is dipropylene glycol Mixture of methyl ether and TEXANOL.

[0075] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com