Medium-high temperature firing soaking-free sliding gate brick and preparation method thereof

A medium-high temperature, sliding brick technology, applied in the field of inorganic non-metallic refractory materials, can solve the problems of a large number of harmful substances, high energy consumption, reduced erosion resistance, etc., and achieve the effect of performance advantages and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

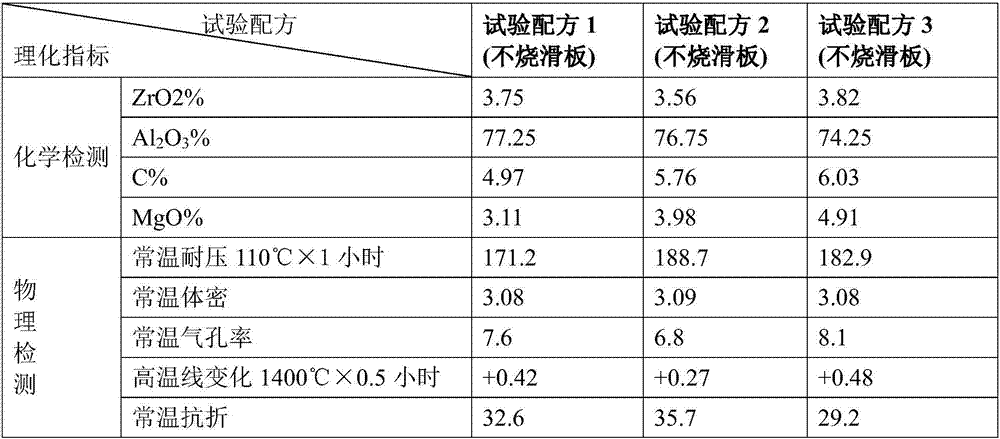

Examples

Embodiment 1

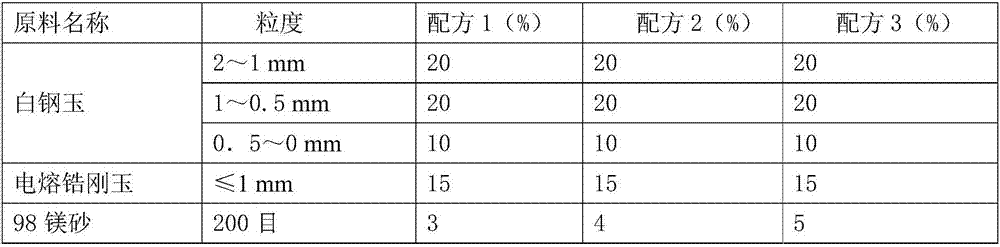

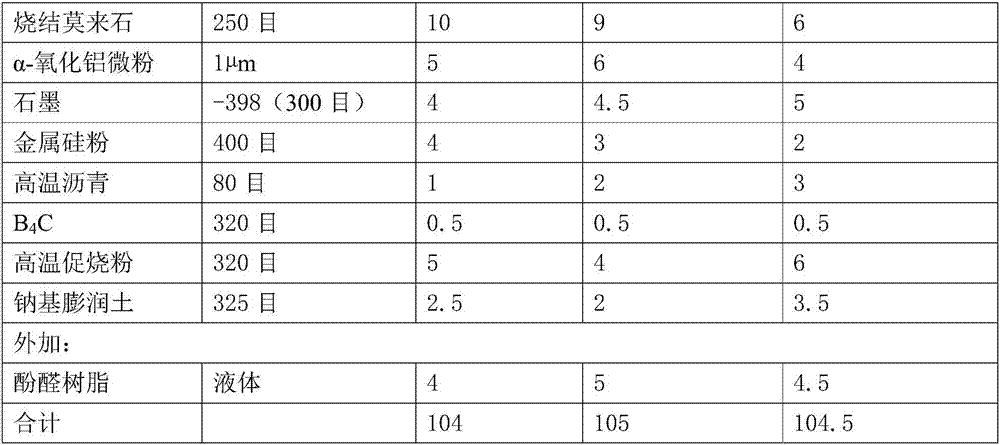

[0036] Raw material specifications are as follows:

[0037] White corundum Al 2 o 3 Content ≥ 98.5%;

[0038] Fused zirconia corundum: Al 2 o 3 Content ≥ 71%, ZrO2 content ≥ 24%;

[0039] 98 magnesia: MgO content ≥ 98%;

[0040] Sintered mullite: Al 2 o 3 Content ≥ 70%;

[0041] α-alumina fine powder (α-Al 2 o 3 ): alumina content ≥ 98%;

[0042] Graphite: C content ≥ 98%;

[0043] Metal silicon powder: Si content ≥ 97%;

[0044] High temperature asphalt: C content ≥ 60%;

[0045] Boron carbide: C content ≥ 20%, B content ≥ 74%;

[0046] High temperature burning powder: Al 2 o 3 Content ≥ 75%;

[0047] Sodium bentonite: Al 2 o 3 Content ≥ 10%, SiO2 content ≥ 65%;

[0048] Phenolic resin: carbon residue 45±4, solid content 75-80%, viscosity 16000-18000mpa.

[0049] The basic production process of the inventive product is: according to the formula in Table 1, alumina raw material (white corundum) and fused zirconia corundum are batched according to the formu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com