Antifouling soaping agent comprising polyoxyethylene ether chain quaternary ammonium salt and preparation method thereof

A technology of polyoxyethylene ether and alcohol polyoxyethylene ether, which is applied in the field of anti-fouling soaping agent and its preparation, can solve the problems of lack of anti-staining ability, not widely used, and high price, and achieve the protection of white ground , Excellent cleaning and dispersing ability, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A kind of antifouling soaping agent containing polyoxyethylene ether chain quaternary ammonium salt of the present embodiment comprises the following components in parts by weight: polyoxyethylene ether chain quaternary ammonium salt cationic surfactant: 15 parts; fatty alcohol Polyoxyethylene ether: 12 parts; Alkyl glycoside APG: 10 parts; Sorbitan laurate: 12.5 parts; Tetrasodium iminodisuccinate: 11 parts; Sodium citrate: 6.5 parts; Sodium tripolyphosphate: 9 parts; defoamer: 2 parts; water: balance.

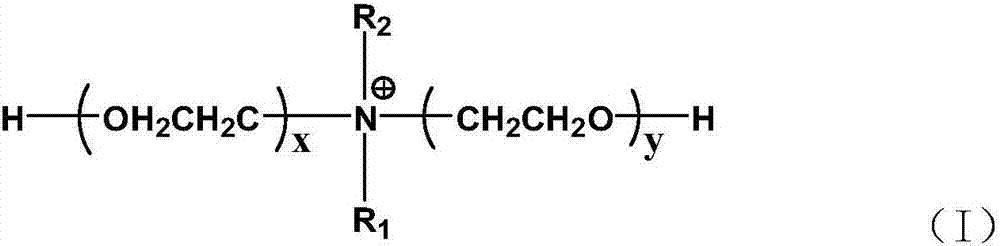

[0045] In the molecular structural formula of the polyoxyethylene ether chain quaternary ammonium salt cationic surfactant, R1 is -CH 2 (CH 2 CH 2 ) 8 CH 3 , R2 is -CH 2 CH 2 OH, x=y=30.

[0046] A kind of preparation method of the antifouling soaping agent containing polyoxyethylene ether chain quaternary ammonium salt, comprises the steps:

[0047] (1) First raise the water temperature to 40°C, then add polyoxyethylene ether chain quaternary ammonium salt cat...

Embodiment 2

[0052] A kind of antifouling soaping agent containing polyoxyethylene ether chain quaternary ammonium salt of the present embodiment comprises the following components in parts by weight: polyoxyethylene ether chain quaternary ammonium salt cationic surfactant: 2 parts; fatty alcohol Polyoxyethylene ether: 15 parts; Alkyl glycoside APG: 5 parts; Sorbitan laurate: 5 parts; Tetrasodium iminodisuccinate: 5 parts; Sodium citrate: 3 parts; Sodium tripolyphosphate: 3 parts; defoamer: 2 parts; water: balance.

[0053] In the molecular structural formula of the polyoxyethylene ether chain quaternary ammonium salt cationic surfactant, R1 is -CH 2 (CH 2 CH 2 ) 3 CH 3 , R2 is x=y=10.

[0054] A kind of preparation method of the antifouling soaping agent containing polyoxyethylene ether chain quaternary ammonium salt, comprises the steps:

[0055] (1) First raise the water temperature to 50°C, then add polyoxyethylene ether chain quaternary ammonium salt cationic surfactant, fatty ...

Embodiment 3

[0060] A kind of antifouling soaping agent containing polyoxyethylene ether chain quaternary ammonium salt of the present embodiment comprises the following components in parts by weight: polyoxyethylene ether chain quaternary ammonium salt cationic surfactant: 25 parts; fatty alcohol Polyoxyethylene ether: 20 parts; Alkyl glycoside APG: 10 parts; Sorbitan laurate: 9 parts; Tetrasodium iminodisuccinate: 12 parts; Sodium citrate: 8 parts; Sodium tripolyphosphate: 5 parts; defoamer: 3 parts; water: balance.

[0061] In the molecular structural formula of the polyoxyethylene ether chain quaternary ammonium salt cationic surfactant, R1 is -CH 2 (CH 2 CH 2 ) 5 CH 3 , R2 is x=y=60.

[0062] A kind of preparation method of the antifouling soaping agent containing polyoxyethylene ether chain quaternary ammonium salt, comprises the steps:

[0063] (1) First raise the water temperature to 60°C, then add polyoxyethylene ether chain quaternary ammonium salt cationic surfactant, fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com