High-humidity vinegar residue gasification direct combustion utilization device and method thereof

A technology of vinegar grains and high humidity, which is applied in the field of high-humidity vinegar grains gasification and direct combustion utilization devices, can solve the problems of insufficient utilization of vinegar grains energy, lower heat transfer efficiency of gas boilers, and potential safety hazards, so as to reduce external supply heat, save storage and landfill space, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

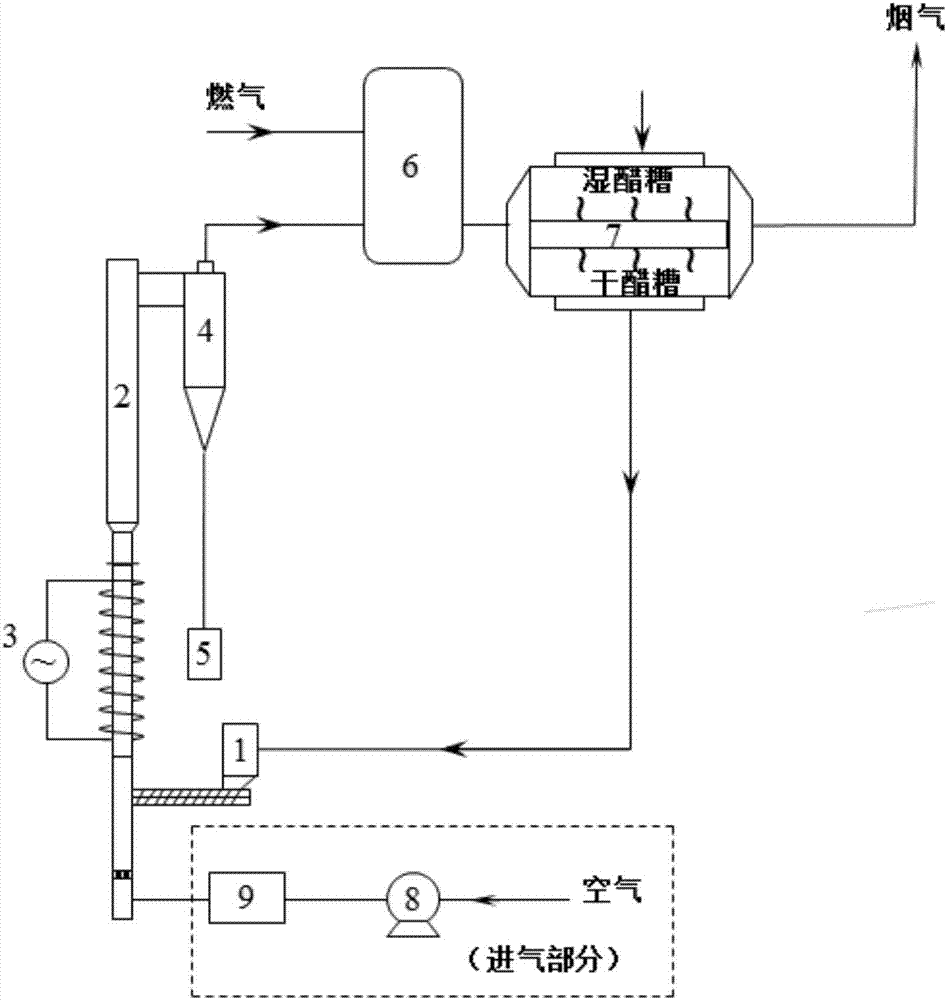

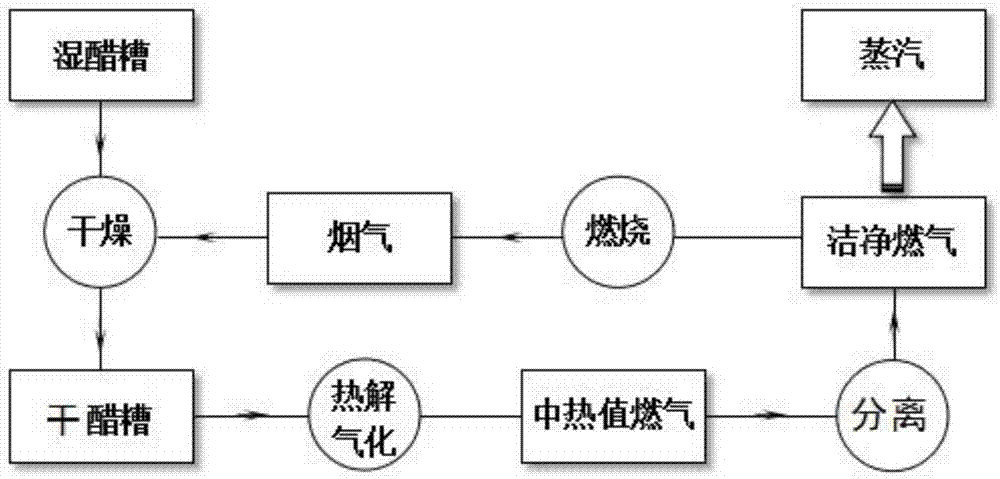

[0041] A company produces and discharges 2.6 million tons of vinegar grains every year. The vinegar grains contain 6% to 10% of crude protein, 2% to 5% of crude fat, 20% to 30% of nitrogen-free extracts, 13% to 17% of ash, and 0.25% of calcium. %~0.45%, phosphorus 0.16%~0.37%. Taking the vinegar grains discharged by the company as the test object, gas is produced on a small-scale test device, and medium calorific value gas is produced and separated to replace or mix with commercial gas for direct combustion to obtain high-temperature steam necessary for the vinegar brewing process.

[0042]First, the high-humidity vinegar grains with a moisture content of 70% are pretreated with quicklime to obtain wet vinegar grains with a moisture content of 30-35%, and then the wet vinegar grains are sent to the vinegar grain drying device 7 at a speed of 220 kg per hour. After treatment, dry vinegar grains with a moisture content of 26% to 30% are obtained; then the dried vinegar grains ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com